Benefits of Using SUS 402, 201, 304L, 316L, 410S, 430 Seamless Stainless steel Metal Pipe in Gas and Petroleum Production

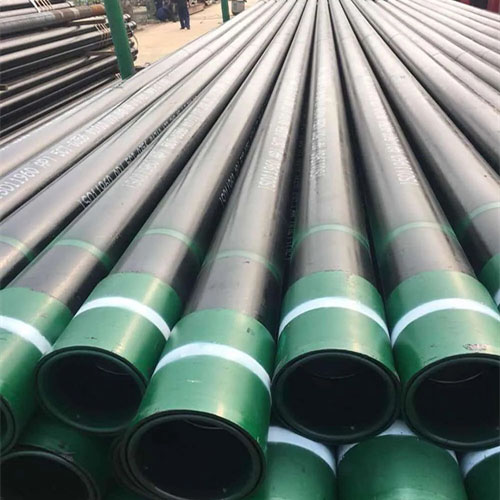

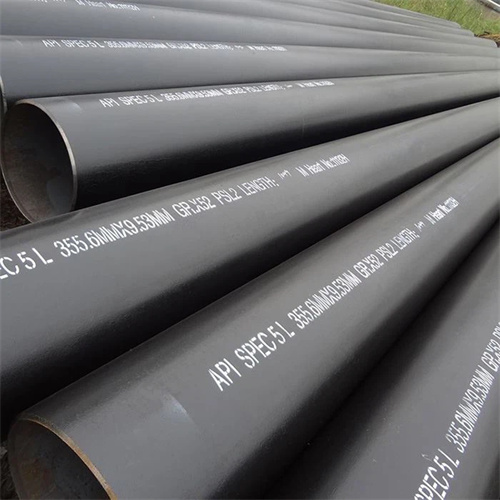

Stainless steel is a popular Material choice for various industries, including gas and petroleum production. Its durability, Corrosion resistance, and high strength make it an ideal material for pipes used in these industries. SUS 402, 201, 304L, 316L, 410S, and 430 are some of the most commonly used grades of stainless steel for seamless metal pipes in gas and petroleum production.

One of the key benefits of using Stainless steel pipes in gas and petroleum production is their resistance to corrosion. The harsh environments in which these pipes operate can cause traditional materials to corrode quickly, leading to leaks and potential safety hazards. Stainless steel, on the other hand, is highly resistant to corrosion, making it a reliable choice for transporting gas and petroleum.

In addition to corrosion resistance, stainless steel pipes are also known for their high strength and durability. This is crucial in gas and petroleum production, where pipes are subjected to high pressure and temperature fluctuations. Stainless steel pipes can withstand these extreme conditions without compromising their structural integrity, ensuring the safe and efficient transportation of gas and petroleum.

Another advantage of using stainless steel pipes in gas and petroleum production is their ease of maintenance. Stainless steel is easy to clean and sanitize, making it a hygienic choice for industries where cleanliness is paramount. This reduces the risk of contamination and ensures the quality of the gas and petroleum being transported through the pipes.

Furthermore, stainless steel pipes are known for their longevity. Unlike other materials that may degrade over time, stainless steel pipes have a long service life, reducing the need for frequent replacements and maintenance. This not only saves time and money but also minimizes downtime in gas and petroleum production operations.

stainless steel flexible hose pipeSUS 402, 201, 304L, 316L, 410S, and 430 are all versatile grades of stainless steel that offer different properties to suit various applications in gas and petroleum production. For example, SUS 304L is a low-carbon variant of SUS 304, making it suitable for applications where Welding is required. SUS 316L, on the other hand, contains molybdenum, which enhances its corrosion resistance, making it ideal for environments with high chloride levels.

Overall, the use of SUS 402, 201, 304L, 316L, 410S, and 430 seamless stainless steel metal pipes in gas and petroleum production offers numerous benefits, including corrosion resistance, high strength, durability, ease of maintenance, and longevity. These properties make stainless steel pipes a reliable and cost-effective choice for transporting gas and petroleum in a safe and efficient manner. By choosing the right grade of stainless steel for the specific requirements of the application, gas and petroleum production companies can ensure the reliability and longevity of their pipelines.