Avantages de l’utilisation de tuyaux sans soudure en acier inoxydable Inconel 400 Uns N04400 600 800 601 dans les applications industrielles

Comparaison des tuyaux sans soudure en acier inoxydable Inconel 400 Uns N04400 600 800 601 avec d’autres matériaux pour divers projets d’ingénierie

En conclusion, les tuyaux sans soudure en acier inoxydable fabriqués à partir d’Inconel 400, Uns N04400, 600, 800 et 601 offrent des propriétés uniques qui les rendent idéaux pour divers projets d’ingénierie. Leur haute résistance, leur résistance à la corrosion et leurs excellentes performances à des températures élevées en font un choix privilégié pour les industries telles que le pétrole et le gaz, le traitement chimique et l’aérospatiale. Grâce à leurs propriétés supérieures et leur facilité de fabrication, ces matériaux sont bien adaptés aux applications exigeantes où la fiabilité et la durabilité sont primordiales.

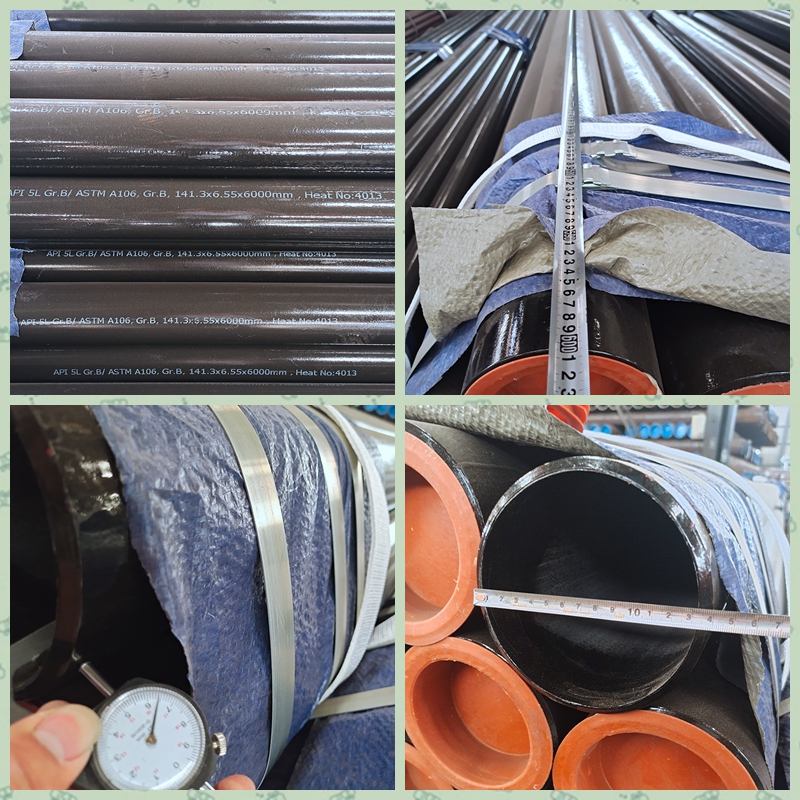

Stainless steel Seamless pipes are widely used in various engineering projects due to their durability, Corrosion resistance, and high strength. Inconel 400, Uns N04400, 600, 800, and 601 are some of the popular materials used for manufacturing stainless steel seamless pipes. These materials offer unique properties that make them suitable for different applications in industries such as Oil and gas, chemical processing, and aerospace.

Inconel 400 is a nickel-copper alloy known for its excellent corrosion resistance in a wide range of environments, including seawater and chemical processing. It is often used in marine applications, heat exchangers, and chemical processing equipment. Uns N04400 is a variant of Inconel 400 with improved Mechanical properties and higher strength. Both materials are suitable for high-temperature applications and offer good weldability.

Inconel 600 is a nickel-chromium alloy that offers excellent resistance to oxidation and corrosion at high temperatures. It is commonly used in furnace components, chemical processing equipment, and nuclear reactors. Inconel 800 is a nickel-iron-chromium alloy with added aluminum and titanium for improved strength and oxidation resistance. It is often used in high-temperature applications such as heat exchangers and steam generators.

Inconel 601 is a nickel-chromium alloy with added aluminum for improved oxidation resistance. It is commonly used in industrial furnaces, heat treatment equipment, and petrochemical processing. These materials offer superior performance in high-temperature and corrosive environments, making them ideal for demanding engineering projects.

When compared to other materials such as Carbon steel, stainless steel seamless pipes made from Inconel 400, Uns N04400, 600, 800, and 601 offer several advantages. They have higher strength, better corrosion resistance, and superior performance at elevated temperatures. This makes them suitable for applications where reliability and durability are crucial.

Inconel alloys are also known for their excellent resistance to stress corrosion cracking, making them ideal for applications in harsh environments. They can withstand extreme temperatures and pressures without losing their mechanical properties, making them a preferred choice for critical engineering projects.

In addition to their superior performance, stainless steel seamless pipes made from Inconel alloys are also easy to fabricate and install. They can be welded, bent, and machined to meet specific project requirements, making them versatile and cost-effective solutions for a wide range of applications.

In conclusion, stainless steel seamless pipes made from Inconel 400, Uns N04400, 600, 800, and 601 offer unique properties that make them ideal for various engineering projects. Their high strength, corrosion resistance, and excellent performance at elevated temperatures make them a preferred choice for industries such as oil and gas, chemical processing, and aerospace. With their superior properties and ease of fabrication, these materials are well-suited for demanding applications where reliability and durability are paramount.