Benefits of Using Stainless steel Seamless Pipe Inconel 400 Uns N04400 600 800 601 in Industrial Applications

Stainless steel seamless pipes made from Inconel 400, Uns N04400, 600, 800, and 601 are widely used in various industrial applications due to their numerous benefits. These pipes are known for their high strength, Corrosion resistance, and durability, making them ideal for use in demanding environments. In this article, we will explore the benefits of using stainless steel seamless pipes in industrial applications.

One of the key advantages of stainless steel seamless pipes is their superior corrosion resistance. These pipes are highly resistant to corrosion from chemicals, acids, and high temperatures, making them suitable for use in harsh industrial environments. This corrosion resistance helps to extend the lifespan of the pipes, reducing the need for frequent maintenance and replacement.

In addition to their corrosion resistance, stainless steel seamless pipes are also known for their high strength. These pipes can withstand high pressure and temperature conditions, making them ideal for use in applications where strength and durability are essential. The high strength of stainless steel seamless pipes helps to ensure the integrity of the piping system, reducing the risk of leaks and failures.

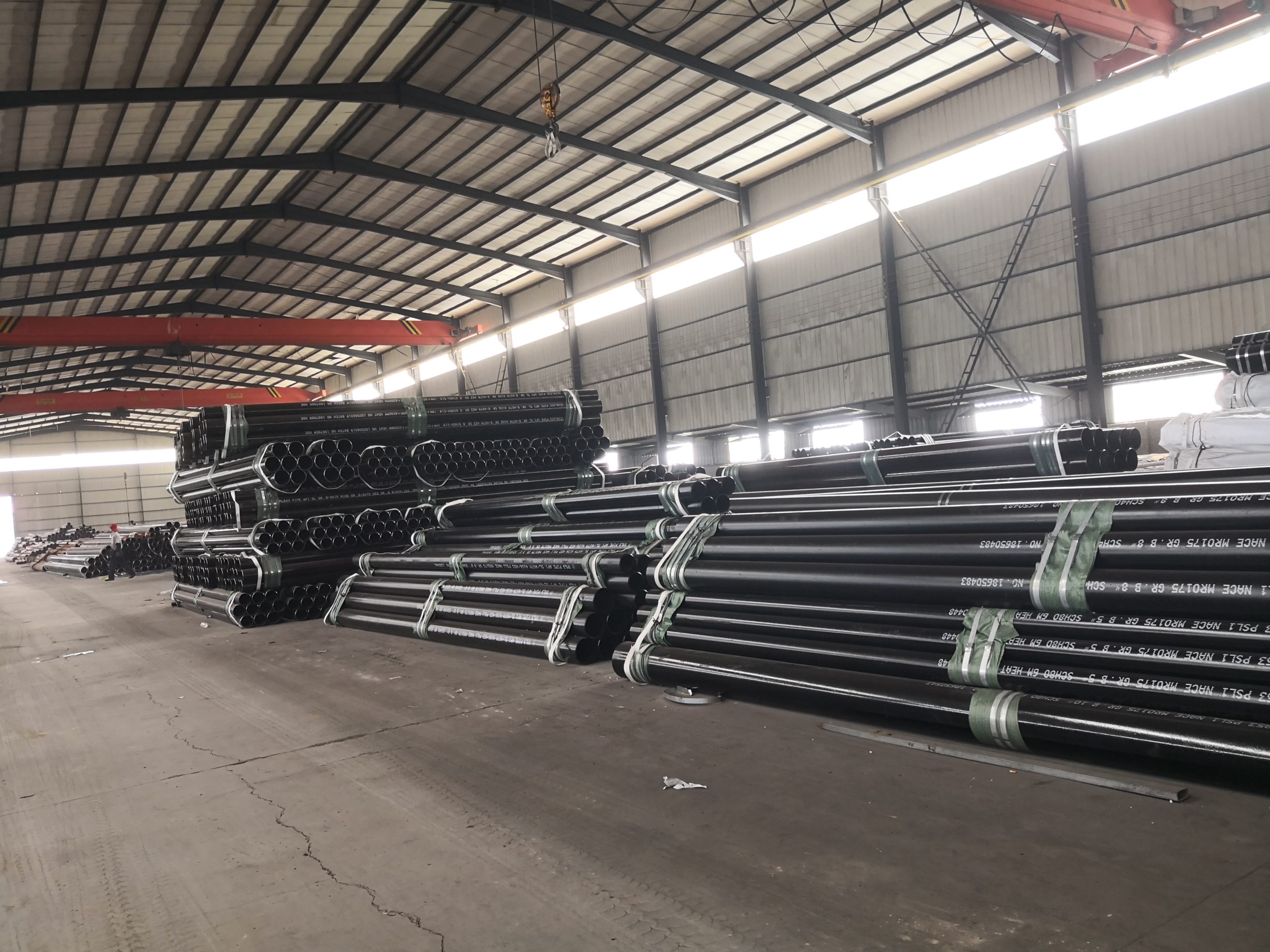

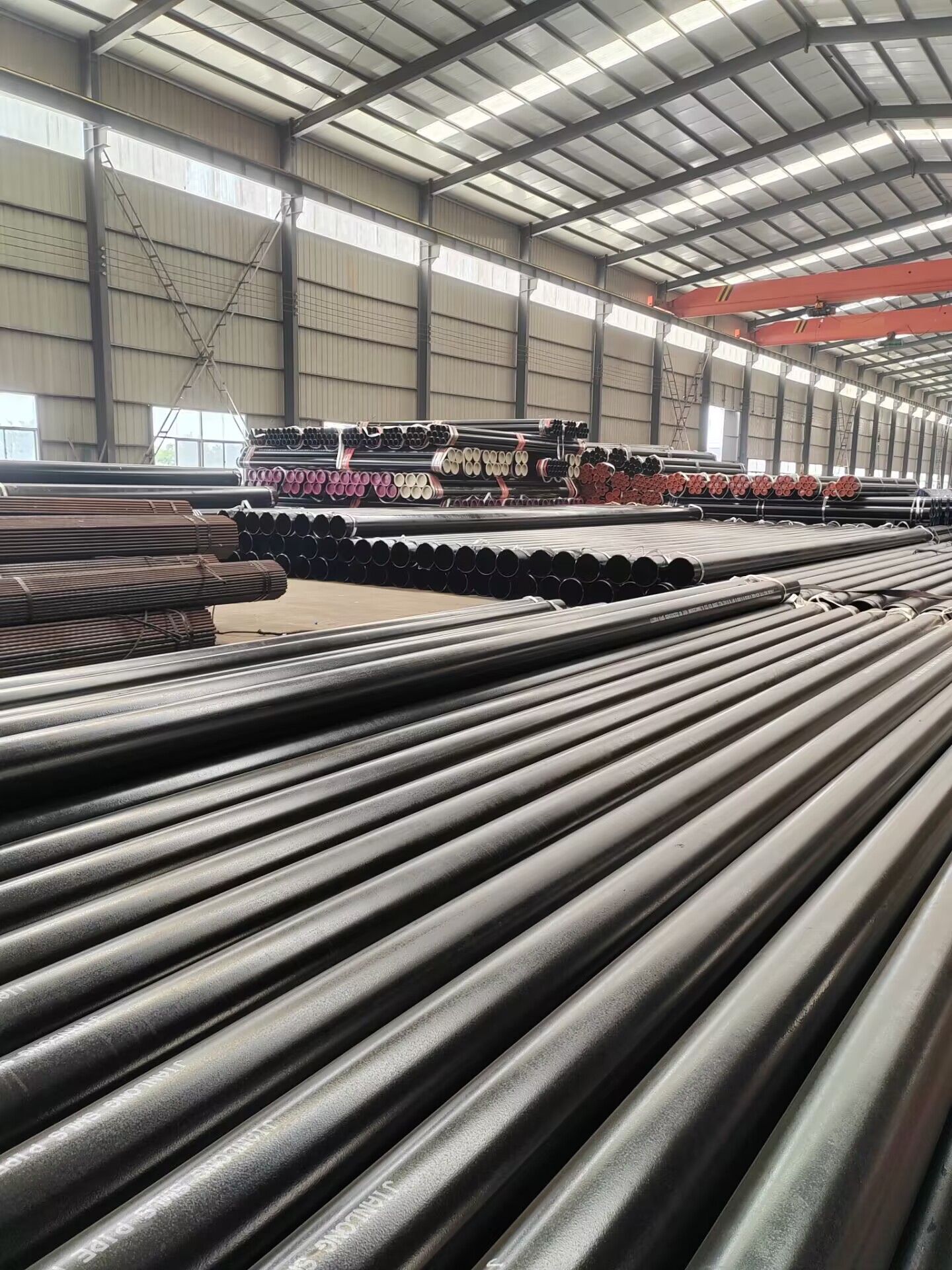

Another benefit of using stainless steel seamless pipes is their versatility. These pipes can be easily customized to meet the specific requirements of different industrial applications. Whether you need a pipe with a specific diameter, Length, or thickness, stainless steel seamless pipes can be tailored to your exact specifications. This versatility makes these pipes suitable for a wide range of industrial applications, from chemical processing to Oil and gas production.

Furthermore, stainless steel seamless pipes are easy to install and maintain. These pipes can be welded together seamlessly, creating a leak-proof and durable piping system. Once installed, stainless steel seamless pipes require minimal maintenance, reducing downtime and operational costs. This ease of installation and maintenance makes stainless steel seamless pipes a cost-effective choice for industrial applications.

2 inch square Tubing near meIn conclusion, stainless steel seamless pipes made from Inconel 400, Uns N04400, 600, 800, and 601 offer numerous benefits for industrial applications. From their superior corrosion resistance and high strength to their versatility and ease of installation, these pipes are an excellent choice for demanding environments. By choosing stainless steel seamless pipes, industrial companies can ensure the reliability and longevity of their piping systems, leading to improved efficiency and productivity.

Comparison of Stainless Steel Seamless Pipe Inconel 400 Uns N04400 600 800 601 with Other Materials for Various Engineering Projects

Stainless steel seamless pipes are widely used in various engineering projects due to their durability, corrosion resistance, and high strength. Inconel 400, Uns N04400, 600, 800, and 601 are some of the popular materials used for manufacturing stainless steel seamless pipes. These materials offer unique properties that make them suitable for different applications in industries such as oil and gas, chemical processing, and aerospace.

Inconel 400 is a nickel-copper alloy known for its excellent corrosion resistance in a wide range of environments, including seawater and chemical processing. It is often used in marine applications, heat exchangers, and chemical processing equipment. Uns N04400 is a variant of Inconel 400 with improved Mechanical properties and higher strength. Both materials are suitable for high-temperature applications and offer good weldability.

Inconel 600 is a nickel-chromium alloy that offers excellent resistance to oxidation and corrosion at high temperatures. It is commonly used in furnace components, chemical processing equipment, and nuclear reactors. Inconel 800 is a nickel-iron-chromium alloy with added aluminum and titanium for improved strength and oxidation resistance. It is often used in high-temperature applications such as heat exchangers and steam generators.

Inconel 601 is a nickel-chromium alloy with added aluminum for improved oxidation resistance. It is commonly used in industrial furnaces, heat treatment equipment, and petrochemical processing. These materials offer superior performance in high-temperature and corrosive environments, making them ideal for demanding engineering projects.

When compared to other materials such as Carbon steel, stainless steel seamless pipes made from Inconel 400, Uns N04400, 600, 800, and 601 offer several advantages. They have higher strength, better corrosion resistance, and superior performance at elevated temperatures. This makes them suitable for applications where reliability and durability are crucial.

Inconel alloys are also known for their excellent resistance to stress corrosion cracking, making them ideal for applications in harsh environments. They can withstand extreme temperatures and pressures without losing their mechanical properties, making them a preferred choice for critical engineering projects.

In addition to their superior performance, stainless steel seamless pipes made from Inconel alloys are also easy to fabricate and install. They can be welded, bent, and machined to meet specific project requirements, making them versatile and cost-effective solutions for a wide range of applications.

In conclusion, stainless steel seamless pipes made from Inconel 400, Uns N04400, 600, 800, and 601 offer unique properties that make them ideal for various engineering projects. Their high strength, corrosion resistance, and excellent performance at elevated temperatures make them a preferred choice for industries such as oil and gas, chemical processing, and aerospace. With their superior properties and ease of fabrication, these materials are well-suited for demanding applications where reliability and durability are paramount.