Benefits of Using Hot Dipped Hollow Tube Pre Galvanized Pipes for Greenhouse Construction

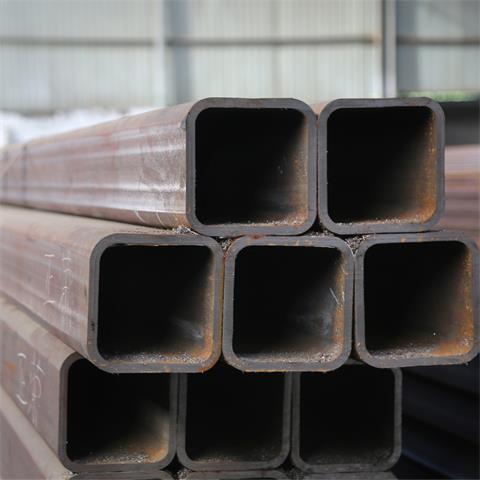

When it comes to constructing a greenhouse, choosing the right materials is crucial to ensure the longevity and efficiency of the structure. One popular option for greenhouse construction is the use of hot dipped hollow tube pre galvanized pipes. These pipes are available in various shapes and sizes, including square and round, and can be customized to fit the specific needs of your greenhouse project.

One of the key benefits of using hot dipped hollow tube pre galvanized pipes for greenhouse construction is their durability. These pipes are coated with a layer of zinc during the manufacturing process, which helps protect them from corrosion and rust. This means that they are able to withstand the harsh environmental conditions that are often present in greenhouse settings, such as high humidity and exposure to water.

In addition to their durability, hot dipped hollow tube pre galvanized pipes are also known for their strength. This makes them an ideal choice for supporting the Weight of the greenhouse structure, as well as any additional equipment or plants that may be housed inside. Whether you are using these pipes for the frame of the greenhouse or for shelving and support structures, you can trust that they will provide the stability and strength needed to keep your greenhouse standing strong for years to come.

Another benefit of using hot dipped hollow tube pre galvanized pipes for greenhouse construction is their versatility. These pipes can be easily welded or connected using various fittings, making them suitable for a wide range of applications within the greenhouse. Whether you are building a simple hoop house or a more complex multi-level greenhouse, these pipes can be customized to fit your specific design requirements.

Furthermore, hot dipped hollow tube pre galvanized pipes are also known for their cost-effectiveness. Compared to other materials commonly used in greenhouse construction, such as wood or aluminum, these pipes are often more affordable while still offering the same level of durability and strength. This can help you save money on your greenhouse project without compromising on the quality of the materials used.

In addition to their durability, strength, versatility, and cost-effectiveness, hot dipped hollow tube pre galvanized pipes are also environmentally friendly. The zinc coating used on these pipes is non-toxic and recyclable, making them a sustainable choice for greenhouse construction. By choosing these pipes for your greenhouse project, you can reduce your environmental impact and contribute to a more sustainable future.

In conclusion, hot dipped hollow tube pre galvanized pipes offer a wide range of benefits for greenhouse construction. From their durability and strength to their versatility and cost-effectiveness, these pipes are an excellent choice for anyone looking to build a greenhouse that will stand the test of time. By choosing these pipes for your greenhouse project, you can ensure that your structure is built to last while also making a positive impact on the environment.

Comparison of Seamless, ERW, and Welded Carbon steel Pipes for Greenhouse Applications

When it comes to choosing the right type of carbon steel Pipe for greenhouse applications, there are several options to consider. Seamless, ERW, and welded carbon steel pipes all have their own unique characteristics and advantages, making it important to understand the differences between them in order to make an informed decision.

Seamless carbon steel pipes are made by piercing a solid billet of steel and then rolling it to form a hollow tube. This process results in a pipe with no seams or welds, making it stronger and more reliable than other types of pipes. Seamless pipes are also more resistant to corrosion and can withstand higher temperatures and pressures, making them ideal for greenhouse applications where durability is key.

ERW (Electric Resistance Welded) carbon steel pipes are made by passing a high-frequency electrical current through the steel strip, causing it to heat up and form a weld. ERW pipes are less expensive to produce than seamless pipes and are suitable for a wide range of applications, including greenhouse construction. However, the weld seam in ERW pipes can be a weak point that is susceptible to corrosion and failure over time.

https://youtube.com/watch?v=4erHivkeuv4

Welded carbon steel pipes are made by Welding together two or more pieces of steel to form a single pipe. Welded pipes are less expensive than seamless pipes and are commonly used in greenhouse construction due to their affordability and availability. However, welded pipes are not as strong or durable as seamless pipes and may be more prone to corrosion and leaks.

When comparing seamless, ERW, and welded carbon steel pipes for greenhouse applications, it is important to consider the specific requirements of the project. Seamless pipes are the strongest and most durable option, making them ideal for high-pressure and high-temperature applications. ERW pipes are a cost-effective alternative that is suitable for a wide range of greenhouse projects. Welded pipes are the most affordable option but may not be as reliable or long-lasting as seamless or ERW pipes.

In conclusion, the choice between seamless, ERW, and welded carbon steel pipes for greenhouse applications will depend on factors such as budget, project requirements, and durability. Seamless pipes are the strongest and most reliable option, while ERW pipes offer a cost-effective alternative. Welded pipes are the most affordable option but may not be as durable or reliable as seamless or ERW pipes. By understanding the differences between these types of pipes, greenhouse builders can make an informed decision that meets their specific needs and requirements.