Benefits of Using Large Diameter SMLS Pipe in Various Industries

Large diameter Seamless (SMLS) pipes are a crucial component in various industries due to their durability, strength, and versatility. These pipes are manufactured without any Welding seams, making them ideal for high-pressure applications where welded pipes may be prone to leaks or failures. In this article, we will explore the benefits of using large diameter SMLS pipes in different industries and why they are preferred over other types of pipes.

One of the key advantages of large diameter SMLS pipes is their superior strength and durability. These pipes are made from high-quality materials such as ASTM A106 Gr. B, Q235, and A53, which are known for their excellent Mechanical properties. This makes them suitable for use in demanding environments where the pipes are subjected to high temperatures, pressure, and corrosive substances. Additionally, the absence of welding seams in SMLS pipes eliminates weak points in the pipe structure, reducing the risk of failure and ensuring long-term reliability.

Another benefit of large diameter SMLS pipes is their smooth internal surface, which allows for efficient fluid flow and minimizes pressure drop. This is particularly important in industries such as Oil and gas, where the transportation of fluids over long distances requires pipes with minimal frictional resistance. The seamless construction of these pipes also eliminates the need for additional fittings or joints, reducing the risk of leaks and improving overall system efficiency.

1 1 4 steel tubingIn addition to their strength and smooth internal surface, large diameter SMLS pipes offer excellent dimensional accuracy and precision. These pipes are manufactured using hot rolled or Cold drawn techniques, ensuring tight tolerances and consistent Wall thickness throughout the Length of the pipe. This level of precision is essential in industries such as construction and infrastructure, where the exact dimensions of the pipes are critical for proper installation and performance.

Large diameter SMLS pipes are also available in a variety of coatings and finishes, including galvanized, GI/GL, black iron, and carbon seamless steel. These coatings provide protection against corrosion, rust, and other environmental factors, extending the lifespan of the pipes and reducing maintenance costs. Additionally, the versatility of these coatings allows for customization based on the specific requirements of each industry, ensuring optimal performance in any application.

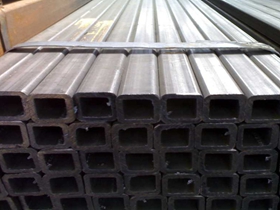

Furthermore, large diameter SMLS pipes are available in round and square shapes, providing flexibility in design and installation. The seamless construction of these pipes allows for easy bending and shaping without compromising structural integrity, making them suitable for a wide range of applications. Whether used in industrial piping systems, structural supports, or mechanical components, large diameter SMLS pipes offer unmatched versatility and reliability.

In conclusion, large diameter SMLS pipes are an essential component in various industries due to their strength, durability, and precision. These pipes offer numerous benefits, including superior mechanical properties, smooth internal surface, dimensional accuracy, and a variety of coatings and finishes. Whether used in high-pressure applications, fluid transportation, or structural construction, large diameter SMLS pipes provide unmatched performance and reliability. With their versatility and durability, these pipes are the preferred choice for industries that demand the highest quality and performance standards.