Benefits of Using Hot Rolled steel Seamless Machinery Steel tube Pipe Hollow Bar

Hot rolled steel seamless machinery steel tube pipe hollow bar is a popular choice in various industries due to its numerous benefits. This type of steel is manufactured through a process that involves heating the steel above its recrystallization temperature and then rolling it into the desired shape. The end result is a strong and durable product that is ideal for use in machinery, construction, and other applications.

1 4 ss tubingOne of the main advantages of using hot rolled steel seamless machinery steel tube pipe hollow bar is its strength. This type of steel is known for its high Tensile strength, which makes it ideal for applications where durability is essential. Whether it is used in heavy machinery or structural components, hot rolled steel seamless machinery steel tube pipe hollow bar can withstand high levels of stress and pressure without deforming or breaking.

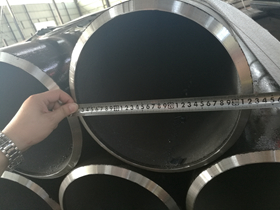

In addition to its strength, hot rolled steel seamless machinery steel tube pipe hollow bar is also known for its versatility. This type of steel can be easily shaped and formed into various sizes and dimensions, making it suitable for a wide range of applications. Whether you need a small diameter tube or a large hollow bar, hot rolled steel seamless machinery steel can be customized to meet your specific requirements.

Another benefit of using hot rolled steel seamless machinery steel tube pipe hollow bar is its cost-effectiveness. Compared to other types of steel, hot rolled steel seamless machinery steel is relatively affordable, making it a cost-effective option for businesses looking to save money on materials. Additionally, the durability and longevity of hot rolled steel seamless machinery steel mean that it will last for a long time, reducing the need for frequent replacements and repairs.

Hot rolled steel seamless machinery steel tube pipe hollow bar is also known for its resistance to corrosion and rust. This type of steel is treated with a protective coating that helps prevent oxidation and corrosion, ensuring that it remains in good condition even in harsh environments. Whether it is exposed to moisture, chemicals, or extreme temperatures, hot rolled steel seamless machinery steel tube pipe hollow bar will maintain its integrity and strength.

Furthermore, hot rolled steel seamless machinery steel tube pipe hollow bar is easy to work with and can be welded, machined, and fabricated to meet specific requirements. This makes it a versatile option for businesses that need a customizable solution for their projects. Whether you need a complex shape or a simple design, hot rolled steel seamless machinery steel can be easily manipulated to achieve the desired outcome.

Overall, hot rolled steel seamless machinery steel tube pipe hollow bar offers numerous benefits for businesses in various industries. From its strength and durability to its cost-effectiveness and versatility, this type of steel is a reliable choice for a wide range of applications. Whether you are in the construction, manufacturing, or automotive industry, hot rolled steel seamless machinery steel tube pipe hollow bar can provide the strength and durability you need to succeed.

Comparison of Different Steel Grades for Manufacturing Machinery Steel Tube Pipe Hollow Bar

Steel is a versatile and essential Material in the manufacturing industry, especially when it comes to producing machinery components like tubes, pipes, and hollow bars. Different grades of steel offer varying properties that make them suitable for specific applications. In this article, we will compare several popular steel grades used in the manufacture of machinery steel tube pipe hollow bars, including 1020, 1045, 4140, 4130, 4340, 40cr, 5140, 40mn2, S235, S355, and 12crmo1V.

One of the most common grades of steel used in machinery manufacturing is 1020 steel. This low Carbon steel grade is known for its excellent weldability and machinability, making it ideal for applications where precise shaping and forming are required. 1020 steel is often used in the production of hydraulic cylinders, gears, and shafts due to its good balance of strength and Ductility.

Another popular steel grade is 1045, a medium carbon steel known for its high tensile strength and wear resistance. 1045 steel is commonly used in the manufacture of gears, axles, and crankshafts where durability and toughness are essential. Its excellent machinability and weldability make it a versatile choice for a wide range of machinery applications.

For applications requiring higher strength and Hardness, steel grades like 4140 and 4130 are preferred. 4140 steel is a chromium-molybdenum Alloy steel known for its high tensile strength and impact resistance. It is commonly used in the production of heavy-duty machinery components like axles, shafts, and gears. 4130 steel, on the other hand, is a low alloy steel with excellent weldability and machinability. It is often used in the aerospace and automotive industries for its high strength-to-Weight ratio.

When it comes to applications requiring superior toughness and Fatigue resistance, steel grades like 4340 are the go-to choice. 4340 steel is a nickel-chromium-molybdenum alloy steel known for its high strength and toughness. It is commonly used in the manufacture of aircraft landing gear, crankshafts, and connecting rods where high fatigue resistance is crucial.

For applications requiring good hardenability and wear resistance, steel grades like 40cr and 5140 are commonly used. 40cr steel is a chromium alloy steel known for its high tensile strength and abrasion resistance. It is often used in the production of gears, shafts, and crankshafts where wear resistance is essential. 5140 steel, on the other hand, is a low alloy steel known for its good hardenability and toughness. It is commonly used in the manufacture of automotive components like axles and crankshafts.

In addition to the aforementioned steel grades, grades like 40mn2, S235, S355, and 12crmo1V are also commonly used in machinery manufacturing. 40mn2 steel is a manganese alloy steel known for its high strength and impact resistance. It is often used in the production of heavy-duty machinery components like axles and gears. S235 and S355 are structural steels known for their high tensile strength and Corrosion resistance. They are commonly used in the construction industry for building structural components like beams and columns. 12crmo1V is a chromium-molybdenum-vanadium alloy steel known for its high temperature strength and creep resistance. It is commonly used in the production of high-temperature machinery components like turbine blades and pressure vessels.

In conclusion, the choice of steel grade for manufacturing machinery steel tube pipe hollow bars depends on the specific requirements of the application. Each steel grade offers unique properties that make it suitable for different applications. By understanding the characteristics of each steel grade, manufacturers can select the most appropriate grade for their machinery components to ensure optimal performance and durability.