Benefits of Using Stainless steel pipes in Industrial Applications

Stainless steel pipes have become a popular choice in various industrial applications due to their numerous benefits. The Chinese factory price round square welded Seamless decorative SS tubes pipes 201 304 321 316 316L stainless steel Pipe/tube is a versatile and durable option for a wide range of industries. In this article, we will explore the advantages of using stainless steel pipes in industrial settings.

5 inch square tubingOne of the key benefits of stainless steel pipes is their Corrosion resistance. Stainless steel is highly resistant to corrosion, rust, and staining, making it an ideal choice for applications where exposure to harsh chemicals or environments is common. This corrosion resistance helps to prolong the lifespan of the pipes, reducing the need for frequent replacements and maintenance.

In addition to corrosion resistance, stainless steel pipes are also known for their strength and durability. Stainless steel is a strong Material that can withstand high temperatures, pressure, and mechanical stress. This makes stainless steel pipes suitable for a wide range of industrial applications, including those that require high levels of durability and reliability.

Another advantage of stainless steel pipes is their hygienic properties. Stainless steel is a non-porous material that is easy to clean and maintain, making it an ideal choice for applications where cleanliness is essential. Stainless steel pipes are commonly used in industries such as food and beverage, pharmaceuticals, and healthcare, where hygiene is a top priority.

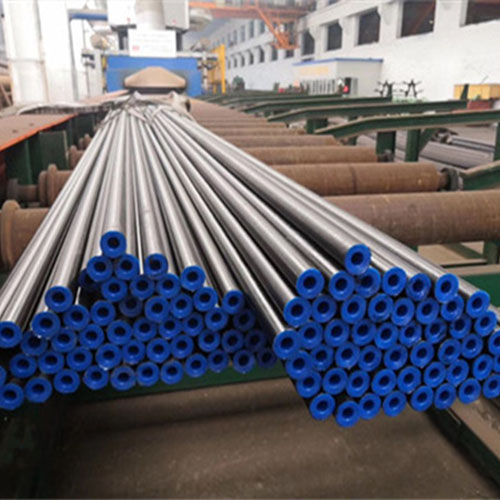

Stainless steel pipes are also known for their aesthetic appeal. The Chinese factory price round square welded seamless decorative SS tubes pipes 201 304 321 316 316L stainless steel pipe/tube offers a sleek and modern look that can enhance the appearance of industrial facilities. Stainless steel pipes are available in a variety of finishes, including polished, brushed, and satin, allowing for customization to suit the aesthetic preferences of different industries.

Furthermore, stainless steel pipes are environmentally friendly. Stainless steel is a recyclable material that can be reused and repurposed, reducing the environmental impact of industrial operations. By choosing stainless steel pipes, industries can contribute to sustainability efforts and reduce their carbon footprint.

In conclusion, the Chinese factory price round square welded seamless decorative SS tubes pipes 201 304 321 316 316L stainless steel pipe/tube offers numerous benefits for industrial applications. From corrosion resistance and durability to hygienic properties and aesthetic appeal, stainless steel pipes are a versatile and reliable option for a wide range of industries. By choosing stainless steel pipes, industries can enjoy long-lasting performance, reduced maintenance costs, and a more sustainable approach to industrial operations.

How to Choose the Right Stainless Steel Pipe for Your Project

When it comes to choosing the right stainless steel pipe for your project, there are several factors to consider. One of the most important considerations is the type of stainless steel that is best suited for your specific application. In this article, we will discuss the different types of stainless steel pipes available, as well as the various factors that should be taken into account when making your selection.

Stainless steel pipes are available in a variety of grades, with the most common being 201, 304, 321, 316, and 316L. Each grade has its own unique properties and characteristics, making it suitable for different applications. For example, 201 stainless steel is a cost-effective option that is often used in decorative applications, while 304 stainless steel is a versatile and widely used grade that is suitable for a wide range of applications.

When choosing a stainless steel pipe, it is important to consider the specific requirements of your project. For example, if you are working on a project that requires high corrosion resistance, you may want to opt for a grade like 316 or 316L, which are known for their excellent corrosion resistance properties. On the other hand, if you are looking for a more cost-effective option for a decorative application, a grade like 201 may be more suitable.

In addition to the grade of stainless steel, you will also need to consider the type of pipe that is best suited for your project. Stainless steel pipes are available in a variety of shapes, including round, square, and rectangular. The shape of the pipe will depend on the specific requirements of your project, as well as the aesthetic considerations that you have in mind.

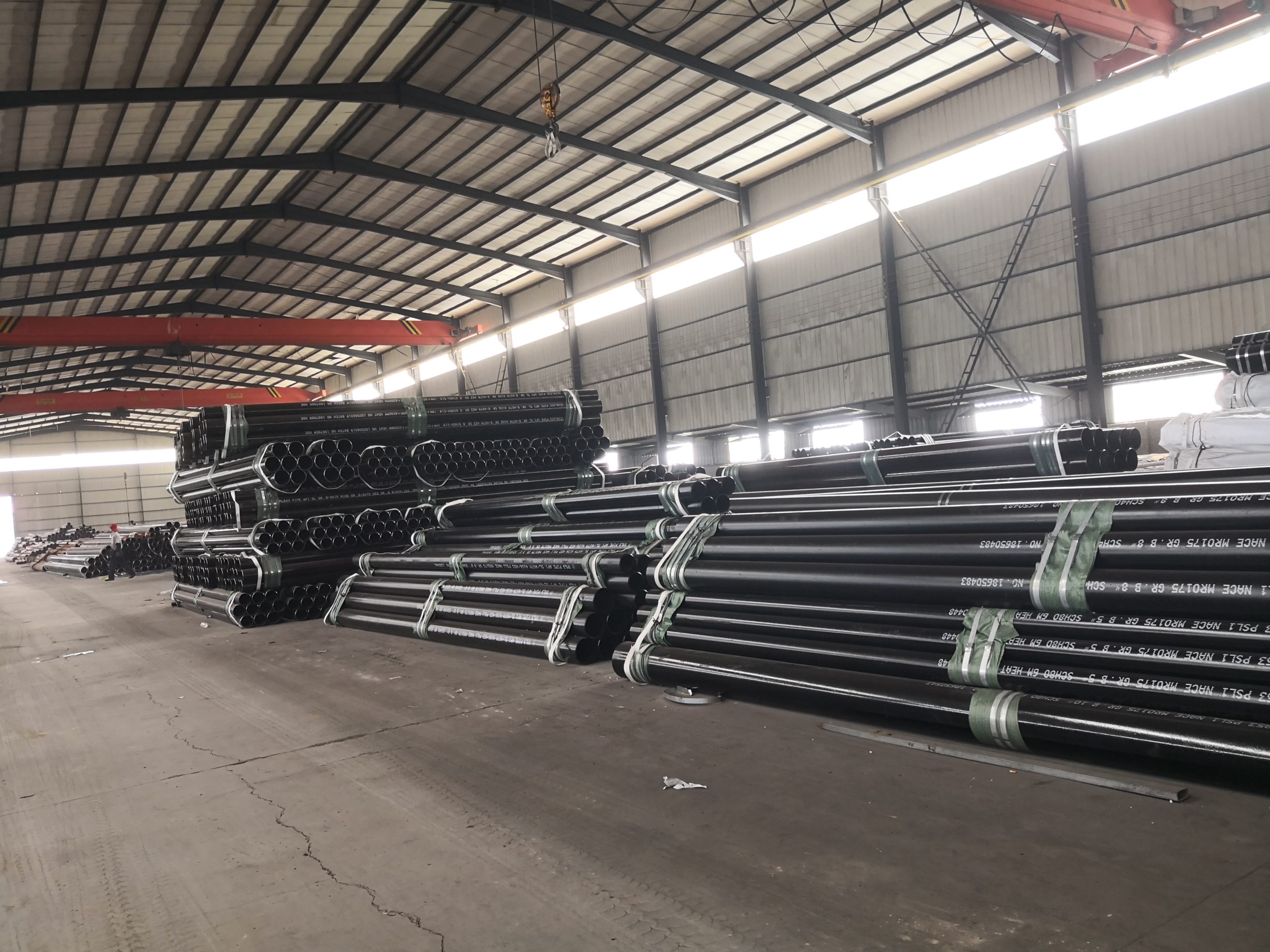

Another important factor to consider when choosing a stainless steel pipe is the manufacturing process. Stainless steel pipes can be either welded or seamless, with each type having its own advantages and disadvantages. Welded pipes are made by Welding together two pieces of stainless steel, while seamless pipes are made from a single piece of stainless steel that is extruded to form the pipe.

Welded stainless steel pipes are generally more cost-effective than seamless pipes, making them a popular choice for many applications. However, seamless pipes are known for their superior strength and durability, making them a better option for high-pressure or high-temperature applications. When choosing between welded and seamless pipes, it is important to consider the specific requirements of your project and select the type of pipe that best meets those requirements.

In conclusion, choosing the right stainless steel pipe for your project is a crucial decision that should not be taken lightly. By considering factors such as the grade of stainless steel, the shape of the pipe, and the manufacturing process, you can ensure that you select a pipe that is best suited for your specific application. Whether you are working on a decorative project or a high-pressure application, there is a stainless steel pipe available that will meet your needs.