The Benefits of Using Carbon steel Pipes in Industrial Applications

Carbon steel pipes are widely used in various industrial applications due to their numerous benefits. These pipes, made from a combination of iron and carbon, offer exceptional strength and durability, making them ideal for handling high-pressure and high-temperature fluids. In this article, we will explore the advantages of using carbon steel pipes in industrial settings. One of the primary benefits of carbon steel pipes is their ability to withstand extreme conditions. These pipes are known for their excellent resistance to corrosion, making them suitable for transporting corrosive fluids such as acids and chemicals. Unlike other materials, carbon steel pipes do not require additional protective coatings, reducing maintenance costs and ensuring long-term reliability.| Item No | Product name | Standard | Steel grade | Size(mm) | Application | |

| 1 | pressure fluid steel Pipe | ASTM A106 | Gr.A、Gr.B、Gr.C | OD:21.3-1220 | boiler,heat exchanger,medium low pipeline | |

| ASTM A53 | Wall:2.0-100 | |||||

| 2 | casing, Oil pipe,coupling | API5CT PSL1、 | group1: J55、 K55、 N80、 R95 | OD:26.7-762 | Steel tube for oil field | |

| PSL2 PSL3 | group2: L80、 C90、 T95 | Wall:2.87-40 | ||||

| group3: P110 | ||||||

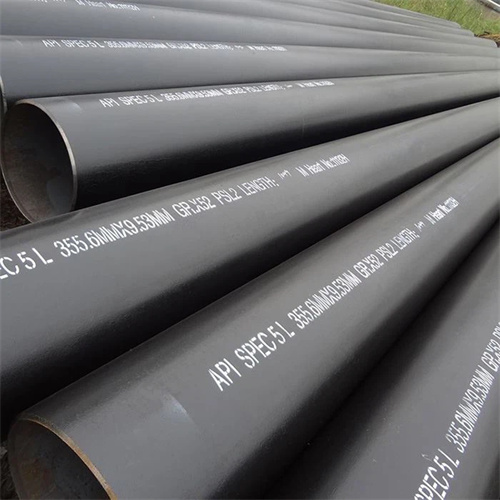

| 3 | pipeline transportation system | API5L | A、B、X42、X46、X52、X60、X65、X70、X80 | OD:26.7-1220 | oil and gas pipeline, refining equipment pipeline | |

| PSL1 | Wall:2.87-100 | |||||

| PSL2 | ||||||

| 4 | mechanical high precision Seamless pipe | ASTM A519 | SAE1018、SAE1020、SAE1045、SAE1518、SAE1541、SAE4130、SAE4135、SAE4140、SAE8620、ST78、ST52、E215、E235、E355、E410、C35E、C45E、25CrMo4、42CrMo4 | OD:21.3-406 | high precision machined seamless tube,construction machine,automobile engine | |

| EN10305-1 | Wall:2.0-40 | |||||

| DIN2391 | ||||||

| GB3639 | ||||||

| 5 | heat exchanger and condenser low carbon cold drawn seamless pipe | ASTM A179 | A179 | OD:6-76.2 | heat exchanger | |

| Wall:1.0-20 | ||||||

| 6 | high pressure carbon steel seamless boiler pipe | ASTM A192 | A192 | OD:12.7-177.8 | high pressure boiler tube | |

| Wall:2.0-25.4 | ||||||

| 7 | boder,superheater unit medium carbon Seamless steel pipe | ASTM A210 | A210A-1 | OD:12.7-127 | high pressure toiler and heat exchanger | |

| A210-C | Wall:0.9-12.7 | |||||

| 8 | boiler,superheater unit femilic Alloy steel pipe | ASTM A213 | T2、T11、T12、T22、T5、T5b、T5C | OD:6-127 | high pressure boiler,superheater unit, heat exchanger alloy steel tube | |

| Wall:0.4-12 | ||||||

| 9 | seamless steel pipe for pressure purpose | EN10216-1 | 195GH、P235GH、P265GH、20MnNb6、16Mo3、13CrMo4-5 | OD:21.3-762 | pressure piping | |

| EN10216-2 | Wall:2.0-40 | |||||

| 10 | gas cylinder seamless steel pipe | GB18248 | 37Mn、34Mn2V、30CrMo、35CrMo、34CrMo4、30CrMnSiA、STH11、STH12、STH21、STH22、STH31 | OD:76-356 | high pressure gas cylinder | |

| JIS G3429 | Wall:2.5-6.0 | |||||

| 11 | the automotive axle pipe | YB/T 5035 | 45#、45Mn2、40MnB、40Cr | OD:76-121 | automobile application | |

| Wall:7.0-28.5 | ||||||

Furthermore, carbon steel pipes have a high Tensile strength, which means they can withstand heavy loads and pressure. This makes them ideal for applications that involve transporting fluids under high pressure, such as oil and gas pipelines. The strength of carbon steel pipes also allows for thinner walls, resulting in lighter and more cost-effective piping systems.

Another advantage of carbon steel pipes is their versatility. These pipes can be easily welded, allowing for the creation of complex piping systems that can be customized to meet specific requirements. The seamless nature of carbon steel pipes also eliminates the risk of leakage, ensuring the safe and efficient transportation of fluids.

Furthermore, carbon steel pipes have a high Tensile strength, which means they can withstand heavy loads and pressure. This makes them ideal for applications that involve transporting fluids under high pressure, such as oil and gas pipelines. The strength of carbon steel pipes also allows for thinner walls, resulting in lighter and more cost-effective piping systems.

Another advantage of carbon steel pipes is their versatility. These pipes can be easily welded, allowing for the creation of complex piping systems that can be customized to meet specific requirements. The seamless nature of carbon steel pipes also eliminates the risk of leakage, ensuring the safe and efficient transportation of fluids.

In addition to their strength and versatility, carbon steel pipes are also highly resistant to shock and vibration. This makes them suitable for applications that involve heavy machinery or equipment, as they can withstand the constant movement and vibrations without compromising their structural integrity. The ability of carbon steel pipes to absorb shocks and vibrations also helps to reduce noise levels, making them ideal for applications where noise control is important.

In addition to their strength and versatility, carbon steel pipes are also highly resistant to shock and vibration. This makes them suitable for applications that involve heavy machinery or equipment, as they can withstand the constant movement and vibrations without compromising their structural integrity. The ability of carbon steel pipes to absorb shocks and vibrations also helps to reduce noise levels, making them ideal for applications where noise control is important.

| Labels | Outside diameter (d/mm) | T&C (kg/m) | Wall thickness (t/mm) | Type of end-finish | |||||||

| 1 | 2 | J55/K55 | M65 | L80/R95 | N80-1/Q | C90/T95 | P110 | Q125 | |||

| 4-1/2 | 9.50 | 114.30 | 14.14 | 5.21 | PS | PS | – | – | – | – | – |

| 10.50 | 114.30 | 15.63 | 5.69 | PSB | PSB | – | – | – | – | – | |

| 11.60 | 114.30 | 17.26 | 6.35 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 13.50 | 114.30 | 20.09 | 7.37 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 15.10 | 114.30 | 22.47 | 8.56 | – | – | – | – | – | PLB | PLB | |

| 5 | 11.50 | 127.00 | 17.11 | 5.59 | PS | PS | – | – | – | – | – |

| 13.00 | 127.00 | 19.35 | 6.43 | PSLB | PSLB | – | – | – | – | – | |

| 15.00 | 127.00 | 22.32 | 7.52 | PSLB | PLB | SLB | PLB | PLB | PLB | ||

| 18.00 | 127.00 | 26.79 | 9.19 | – | PLB | SLB | PLB | PLB | PLB | PLB | |

| 21.40 | 127.00 | 31.85 | 11.10 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 23.20 | 127.00 | 34.53 | 12.14 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 24.10 | 127.00 | 35.87 | 12.70 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 5-1/2 | 14.00 | 139.70 | 20.83 | 6.20 | PS | PS | – | – | – | – | – |

| 15.50 | 139.70 | 23.07 | 6.98 | PSLB | PSLB | – | – | – | – | – | |

| 17.00 | 139.70 | 25.30 | 7.72 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 20.00 | 139.70 | 29.76 | 9.17 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 23.00 | 139.70 | 34.23 | 10.54 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 26.80 | 139.70 | 39.88 | 12.70 | – | – | – | – | P | – | – | |

| 29.70 | 139.70 | 44.20 | 14.27 | – | – | – | – | P | – | – | |

| 32.60 | 139.70 | 48.52 | 15.88 | – | – | – | – | P | – | – | |

| 35.30 | 139.70 | 52.53 | 17.45 | – | – | – | – | P | – | – | |

| 38.00 | 139.70 | 56.55 | 19.05 | – | – | – | – | P | – | – | |

| 40.50 | 139.70 | 60.27 | 20.62 | – | – | – | – | P | – | – | |

| 43.10 | 139.70 | 64.14 | 22.22 | – | – | – | – | P | – | – | |

| 6-5/8 | 20.00 | 168.28 | 29.76 | 7.32 | PSLB | PSLB | – | – | – | – | – |

| 24.00 | 168.28 | 35.72 | 8.94 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 28.00 | 168.28 | 41.67 | 10.59 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 32.00 | 168.28 | 47.62 | 12.06 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 7 | 17.00 | 177.80 | 25.30 | 5.87 | – | – | – | – | – | – | – |

| 20.00 | 177.80 | 29.76 | 6.91 | PS | PS | – | – | – | – | – | |

| 23.00 | 177.80 | 34.23 | 8.05 | PSLB | PLB | PLB | PLB | PLB | – | – | |

| 26.00 | 177.80 | 38.69 | 9.19 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 29.00 | 177.80 | 43.16 | 10.36 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 32.00 | 177.80 | 47.62 | 11.51 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 35.00 | 177.80 | 52.09 | 12.65 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 38.00 | 177.80 | 56.55 | 13.72 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 42.70 | 177.80 | 63.55 | 15.88 | – | – | – | – | P | – | – | |

| 46.40 | 177.80 | 69.05 | 17.45 | – | – | – | – | P | – | – | |

| 50.10 | 177.80 | 74.56 | 19.05 | – | – | – | – | P | – | – | |

| 53.60 | 177.80 | 79.77 | 20.62 | – | – | – | – | P | – | – | |

| 57.10 | 177.80 | 84.98 | 22.22 | – | – | – | – | P | – | – | |

| 7-5/8 | 24.00 | 193.68 | 35.72 | 7.62 | – | – | – | – | – | – | |

| 26.40 | 193.68 | 39.29 | 8.33 | PSLB | PSLB | PLB | PLB | PLB | – | – | |

| 29.70 | 193.68 | 44.20 | 9.52 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 33.70 | 193.68 | 50.15 | 10.92 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 39.00 | 193.68 | 58.04 | 12.70 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 42.80 | 193.68 | 63.69 | 14.27 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 45.30 | 193.68 | 67.42 | 15.11 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 47.10 | 193.68 | 70.09 | 15.88 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 51.20 | 193.68 | 76.20 | 17.45 | – | – | – | – | P | – | – | |

| 55.30 | 193.68 | 82.30 | 19.05 | – | – | – | – | P | – | – | |

| 7-3/4 | 46.10 | 196.85 | 68.61 | 15.11 | – | – | P | P | P | P | P |

| 8-5/8 | 24.00 | 219.08 | 35.72 | 6.71 | PS | PS | – | – | – | – | – |

| 28.00 | 219.08 | 41.67 | 7.72 | PS | – | – | – | – | – | ||

| 32.00 | 219.08 | 47.62 | 8.94 | PSLB | PSLB | – | – | – | – | – | |

| 36.00 | 219.08 | 53.58 | 10.16 | PSLB | PSLB | PLB | PLB | PLB | PLB | – | |

| 40.00 | 219.08 | 59.53 | 11.43 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 44.00 | 219.08 | 65.48 | 12.70 | – | – | PLB | PLB | PLB | PLB | – | |

| 49.00 | 219.08 | 72.92 | 14.15 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 9-5/8 | 32.30 | 244.48 | 48.07 | 7.92 | – | – | – | – | – | – | – |

| 36.00 | 244.48 | 53.58 | 8.94 | PSLB | PSLB | – | – | – | – | – | |

| 40.00 | 244.48 | 59.53 | 10.03 | PSLB | PSLB | PLB | PLB | PLB | – | – | |

| 43.50 | 244.48 | 64.74 | 11.05 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 47.00 | 244.48 | 69.95 | 11.99 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 53.50 | 244.48 | 79.62 | 13.84 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 58.40 | 244.48 | 86.91 | 15.11 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 59.40 | 244.48 | 88.40 | 15.47 | – | – | – | – | P | – | – | |

| 64.90 | 244.48 | 96.58 | 17.07 | – | – | – | – | P | – | – | |

| 70.30 | 244.48 | 104.62 | 18.64 | – | – | – | – | P | – | – | |

| 75.60 | 244.48 | 112.51 | 20.24 | – | – | – | – | P | – | – | |

| 10-3/4 | 32.75 | 273.05 | 48.74 | 7.09 | – | – | – | – | – | – | – |

| 40.50 | 273.05 | 60.27 | 8.89 | PSB | PSB | – | – | – | – | – | |

| 45.50 | 273.05 | 67.71 | 10.16 | PSB | PSB | – | – | – | – | – | |

| 51.00 | 273.05 | 75.90 | 11.43 | PSB | PSB | PSB | PSB | PSB | PSB | – | |

| 55.50 | 273.05 | 82.60 | 12.57 | – | PSB | PSB | PSB | PSB | PSB | – | |

| 60.70 | 273.05 | 90.33 | 13.84 | – | – | – | – | PSB | PSB | PSB | |

| 65.70 | 273.05 | 97.77 | 15.11 | – | – | – | – | PSB | PSB | PSB | |

| 73.20 | 273.05 | 108.94 | 17.07 | – | – | – | – | P | – | – | |

| 79.20 | 273.05 | 117.87 | 18.64 | – | – | – | – | P | – | – | |

| 85.30 | 273.05 | 126.94 | 20.24 | – | – | – | – | P | – | – | |

| 11-3/4 | 42.00 | 298.45 | 62.50 | 8.46 | – | – | – | – | – | – | – |

| 47.00 | 298.45 | 69.95 | 9.53 | PSB | PSB | – | – | – | – | – | |

| 54.00 | 298.45 | 80.36 | 11.05 | PSB | PSB | – | – | – | – | – | |

| 60.00 | 298.45 | 89.29 | 12.42 | PSB | PSB | PSB | PSB | PSB | PSB | PSB | |

| 65.00 | 298.45 | 96.73 | 13.56 | – | – | P | P | P | P | P | |

| 71.00 | 298.45 | 105.66 | 14.78 | – | – | P | P | P | P | P | |

| 13-3/8 | 48.00 | 339.72 | 71.43 | 8.38 | – | – | – | – | – | – | – |

| 54.50 | 339.72 | 81.11 | 9.65 | PSB | PSB | – | – | – | – | – | |

| 61.00 | 339.72 | 90.78 | 10.92 | PSB | PSB | – | – | – | – | – | |

| 68.00 | 339.72 | 101.20 | 12.19 | PSB | PSB | PSB | PSB | PSB | PSB | – | |

| 72.00 | 339.72 | 107.15 | 13.06 | – | – | PSB | PSB | PSB | PSB | PSB | |

| 16 | 65.00 | 406.40 | 96.73 | 9.53 | – | – | – | – | – | – | – |

| 75.00 | 406.40 | 111.62 | 11.13 | PSB | PSB | – | – | – | – | – | |

| 84.00 | 406.40 | 125.01 | 12.57 | PSB | PSB | – | – | – | – | – | |

| 109.00 | 406.40 | 162.21 | 16.66 | P | – | P | P | – | P | P | |

| 18-5/8 | 87.50 | 473.08 | 130.22 | 11.05 | PSB | PSB | – | – | – | – | – |

| 20 | 94.00 | 508.00 | 139.89 | 11.13 | PSLB | PSLB | – | – | – | – | – |

| 106.50 | 508.00 | 158.49 | 12.70 | PSLB | PSLB | – | – | – | – | – | |

| 133.00 | 508.00 | 197.93 | 16.13 | PSLB | – | – | – | – | – | – | |

| API 5CT L80 Casing Tubing Range Lengths | |||

| Range 1 | Range 2 | Range 3 | |

| CASING (PE/T and C/SF) | |||

| Total range Length, inclusive Permissible variation, max a | 4.88 to 7.62 1.83 | 7.62 to 10.36 | 10.36 to 14.63 1.83 |

| 1.52 | |||

| TUBING AND CASING USED AS TUBING | |||

| (PE/T and C/SF) | |||

| Total range length, inclusive Permissible variation, max a | 6.10 to 7.32 b | 8.53 to 9.75 c | 11.58 to 12.80 d |

| 0.61 | 0.61 | 0.61 | |

| INTEGRAL TUBING CONNECTIONS (including IJ/PE | |||

| and IJ/SF) | |||

| Total range length, inclusive Permissible variation, max a | 6.10 to 7.92 e | 8.53 to 10.36 | 11.58 to 13.72 0.61 |

| 0.61 | 0.61 | ||

| PUP JOINTS | Lengths: 0.61; 0.91; 1.22; 1.83; 2.44; 3.05 and 3.66 e | ||

| Tolerance: ±0.076 | |||

| a Length variation applies to rail car shipment to the point of use and does not apply to order items of less than 18,144 kg of pipe. | |||

| b By agreement between purchaser and manufacturer, the maximum length may be increased to 8.57 m. | |||

| c By agreement between purchaser and manufacturer, the maximum length may be increased to 10.76 m. | |||

| d By agreement between purchaser and manufacturer, the maximum length may be increased to 17.72 m.0.61 m pup joints may be furnished up to 0.91 m long by agreement between purchaser and manufacturer, and lengths other than those listed may be furnished by agreement between purchaser and manufacturer. | |||