Exploring the Benefits of Precision steel tube vs. Seamless Steel Tube

When it comes to steel tubes, there are two main types: precision steel tubes and seamless steel tubes. Both types of tubes have their own unique advantages and disadvantages, and it is important to understand the differences between them in order to make an informed decision when selecting the right type of tube for a particular application.

Precision steel tubes are made from cold-drawn steel and are designed to have a high degree of accuracy and repeatability. They are typically used in applications where tight tolerances are required, such as in the automotive and aerospace industries. Precision steel tubes are also often used in medical and laboratory equipment, as well as in the manufacture of precision instruments. The main advantage of precision steel tubes is that they are highly accurate and can be produced in a wide range of sizes and shapes.

| Applications: | For tubular heat exchangers,condensers,and similar heat transfer apparatuses. |

| Size (mm): | O.D.: 6.0~168.0; W.T.: 1~15; L: max 12000 |

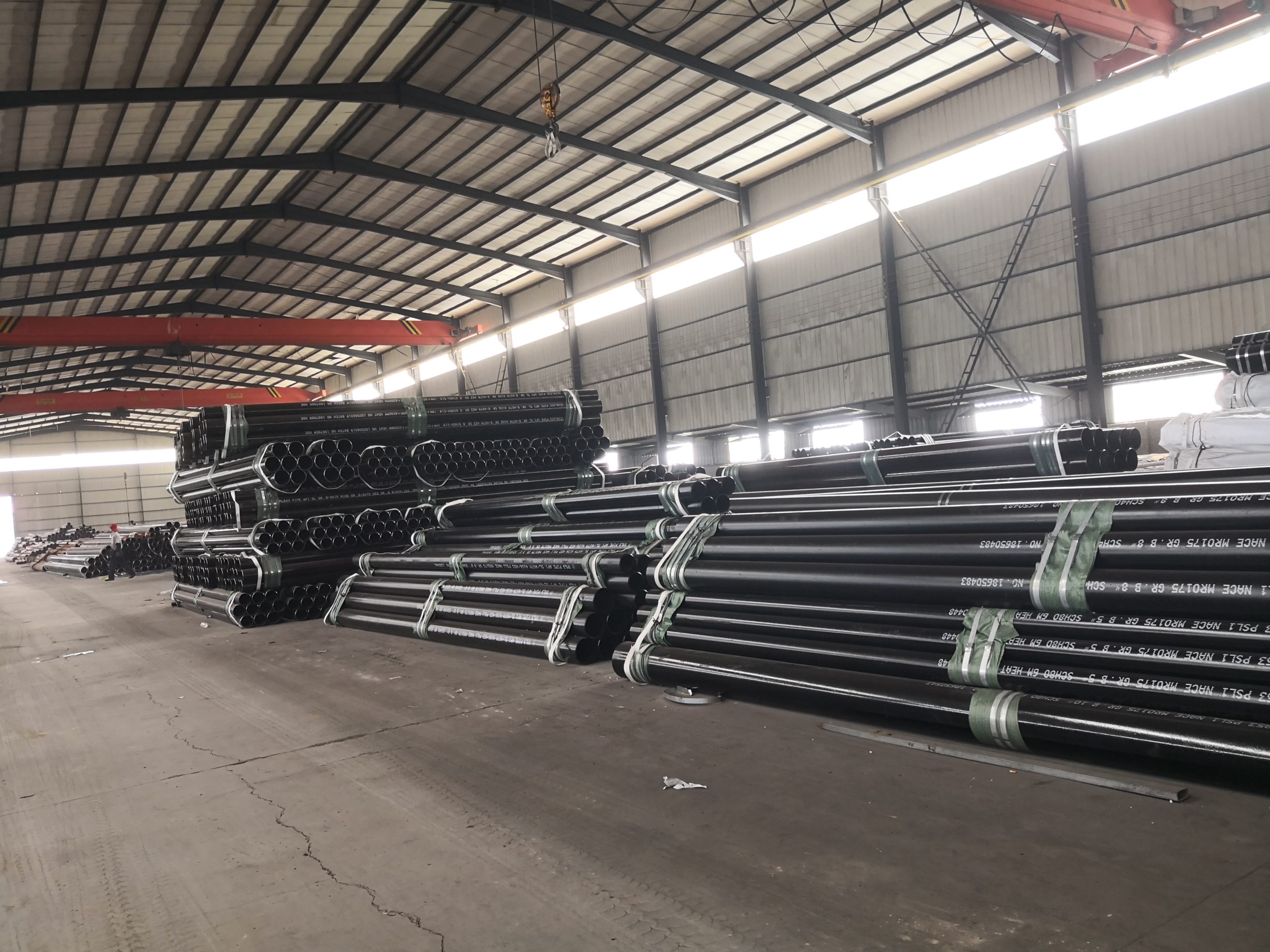

Seamless steel tubes, on the other hand, are made from hot-rolled steel and are designed to be strong and durable. They are often used in applications where strength and durability are more important than accuracy, such as in the construction and engineering industries. Seamless steel tubes are also often used in the manufacture of pipes and other large-scale structures. The main advantage of seamless steel tubes is that they are strong and durable, and can be produced in a wide range of sizes and shapes.

In conclusion, both precision steel tubes and seamless steel tubes have their own unique advantages and disadvantages. It is important to understand the differences between them in order to make an informed decision when selecting the right type of tube for a particular application.