The Benefits of Using Seamless Stainless steel Welding for Processing Steel

Processing steel is a crucial step in the manufacturing industry, as it involves shaping and forming steel into various products that are used in construction, automotive, and other industries. One popular method of processing steel is through welding, which involves joining two pieces of metal together using heat and pressure. When it comes to welding steel, seamless stainless steel welding is a preferred method due to its many benefits.

Seamless stainless steel welding offers a high level of precision and accuracy, as it allows for a smooth and seamless finish. This is important when processing steel, as any imperfections or inconsistencies in the welding process can compromise the integrity of the final product. With seamless stainless steel welding, the weld is virtually invisible, creating a clean and professional look.

Another benefit of using seamless stainless steel welding for processing steel is its durability and strength. Stainless steel is known for its Corrosion resistance and high Tensile strength, making it an ideal Material for welding applications. When steel is processed using seamless stainless steel welding, the resulting product is strong and long-lasting, able to withstand the rigors of everyday use.

In addition to its strength and durability, seamless stainless steel welding also offers excellent thermal conductivity. This means that heat is evenly distributed throughout the welded area, reducing the risk of warping or distortion. This is important when processing steel, as any inconsistencies in the welding process can lead to structural weaknesses in the final product.

Furthermore, seamless stainless steel welding is a cost-effective method of processing steel. While the initial investment in stainless steel welding equipment may be higher than other welding methods, the long-term benefits far outweigh the upfront costs. Stainless steel is a low-maintenance material that requires minimal upkeep, saving time and money in the long run.

When processing steel, it is important to consider the environmental impact of the manufacturing process. Seamless stainless steel welding is a sustainable method of joining steel, as it produces minimal waste and emissions. This is important for companies looking to reduce their carbon footprint and operate in an environmentally responsible manner.

In conclusion, seamless stainless steel welding offers numerous benefits for processing steel. From its precision and durability to its thermal conductivity and cost-effectiveness, seamless stainless steel welding is a preferred method for joining steel in a variety of applications. By choosing seamless stainless steel welding, manufacturers can create high-quality products that are strong, durable, and environmentally friendly.

How to Choose the Right Type of Carbon steel for Welding Galvanized Square Pipes

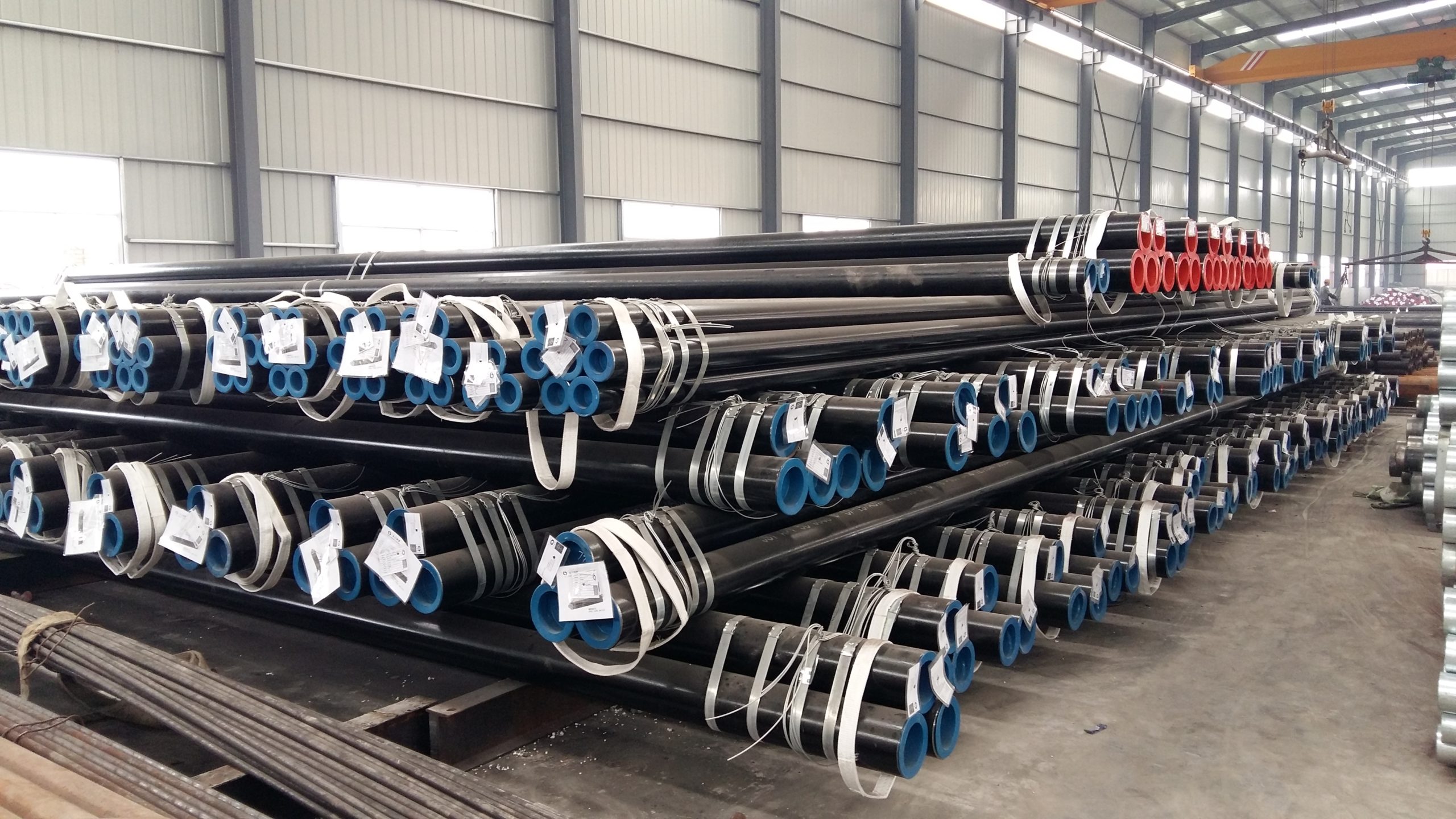

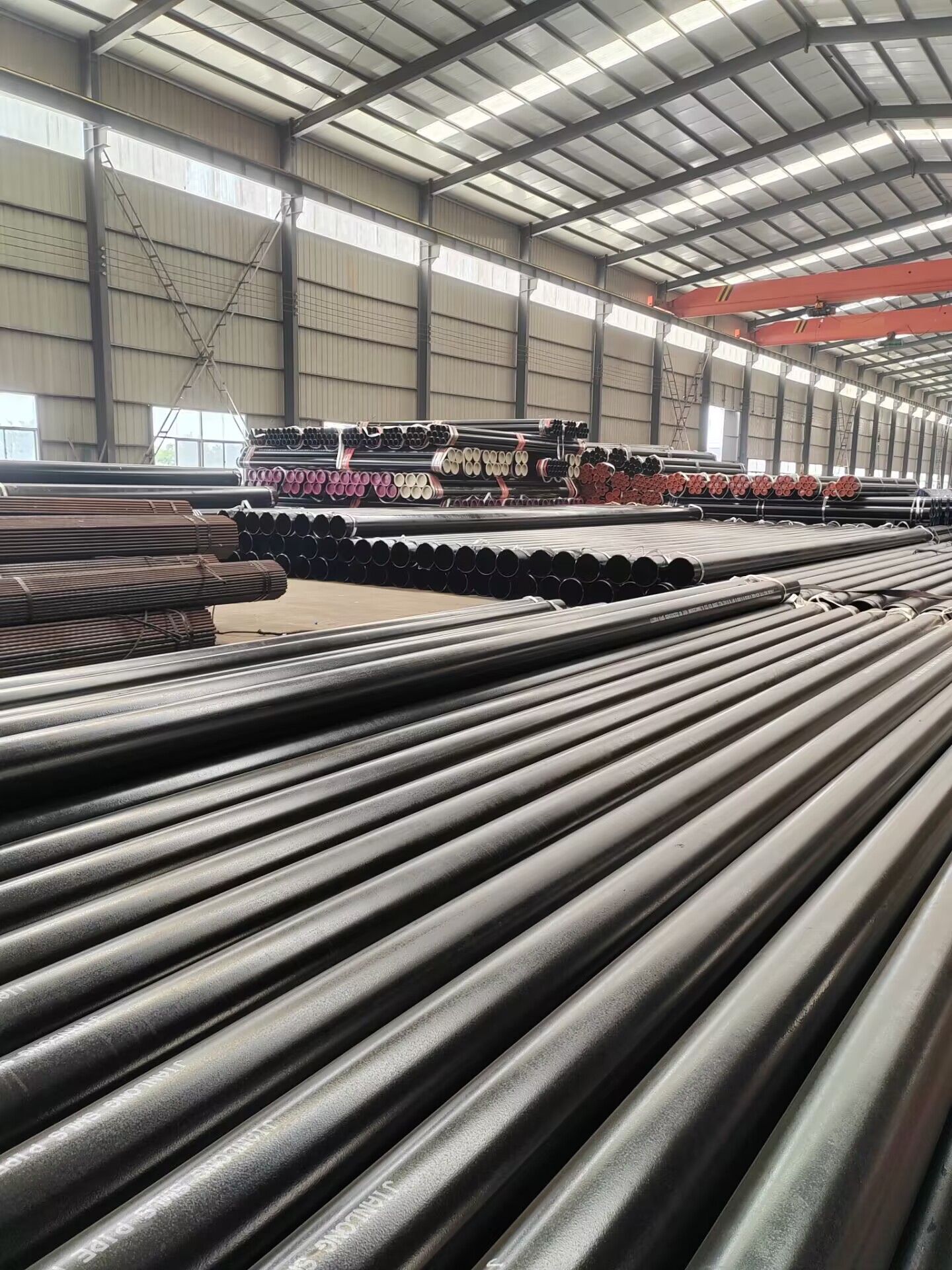

When it comes to choosing the right type of carbon steel for welding galvanized square pipes, there are several factors to consider. The type of carbon steel you choose will impact the strength, durability, and overall quality of the welded joints. In this article, we will discuss the different types of carbon steel commonly used for welding galvanized square pipes and provide some tips on how to choose the right type for your project.

One of the most common types of carbon steel used for welding galvanized square pipes is Q245. Q245 carbon steel is a low carbon steel that is commonly used in structural applications. It has good weldability and is well-suited for welding galvanized square pipes. Q245 carbon steel is also known for its high strength and durability, making it a popular choice for welding applications.

Another popular type of carbon steel for welding galvanized square pipes is Q235B. Q235B carbon steel is a medium carbon steel that is often used in construction and structural applications. It has good weldability and is suitable for welding galvanized square pipes. Q235B carbon steel is known for its high tensile strength and toughness, making it a reliable choice for welding projects.

For more demanding applications, Q345B carbon steel may be a better choice. Q345B carbon steel is a high-strength, low-Alloy steel that is commonly used in structural applications. It has excellent weldability and is well-suited for welding galvanized square pipes. Q345B carbon steel is known for its high strength, toughness, and resistance to corrosion, making it an ideal choice for welding projects that require superior performance.

When choosing the right type of carbon steel for welding galvanized square pipes, it is important to consider the specific requirements of your project. Factors such as the size and thickness of the pipes, the welding process used, and the environmental conditions in which the pipes will be used can all impact the type of carbon steel that is best suited for the job.

In addition to the type of carbon steel, it is also important to consider the surface finish of the pipes. Seamless, hexagonal, and irregular pipes are all common options for welding galvanized square pipes. Each type of Pipe has its own unique characteristics and advantages, so it is important to choose the right type based on the specific requirements of your project.

In conclusion, choosing the right type of carbon steel for welding galvanized square pipes is essential for ensuring the strength, durability, and overall quality of the welded joints. By considering factors such as the type of carbon steel, the surface finish of the pipes, and the specific requirements of your project, you can select the best type of carbon steel for your welding needs. Whether you choose Q245, Q235B, Q345B, or another type of carbon steel, be sure to carefully evaluate your options and select the type that is best suited for your project.