Benefits of Using Seamless Pipe in Industrial Applications

Seamless pipes are a crucial component in various industrial applications due to their numerous benefits and advantages. These pipes are manufactured without any Welding seams, which makes them stronger and more reliable than welded pipes. The seamless pipe manufacturing process involves extruding a solid billet through a die to create a hollow tube. This results in a pipe with uniform thickness and consistent quality throughout its Length.

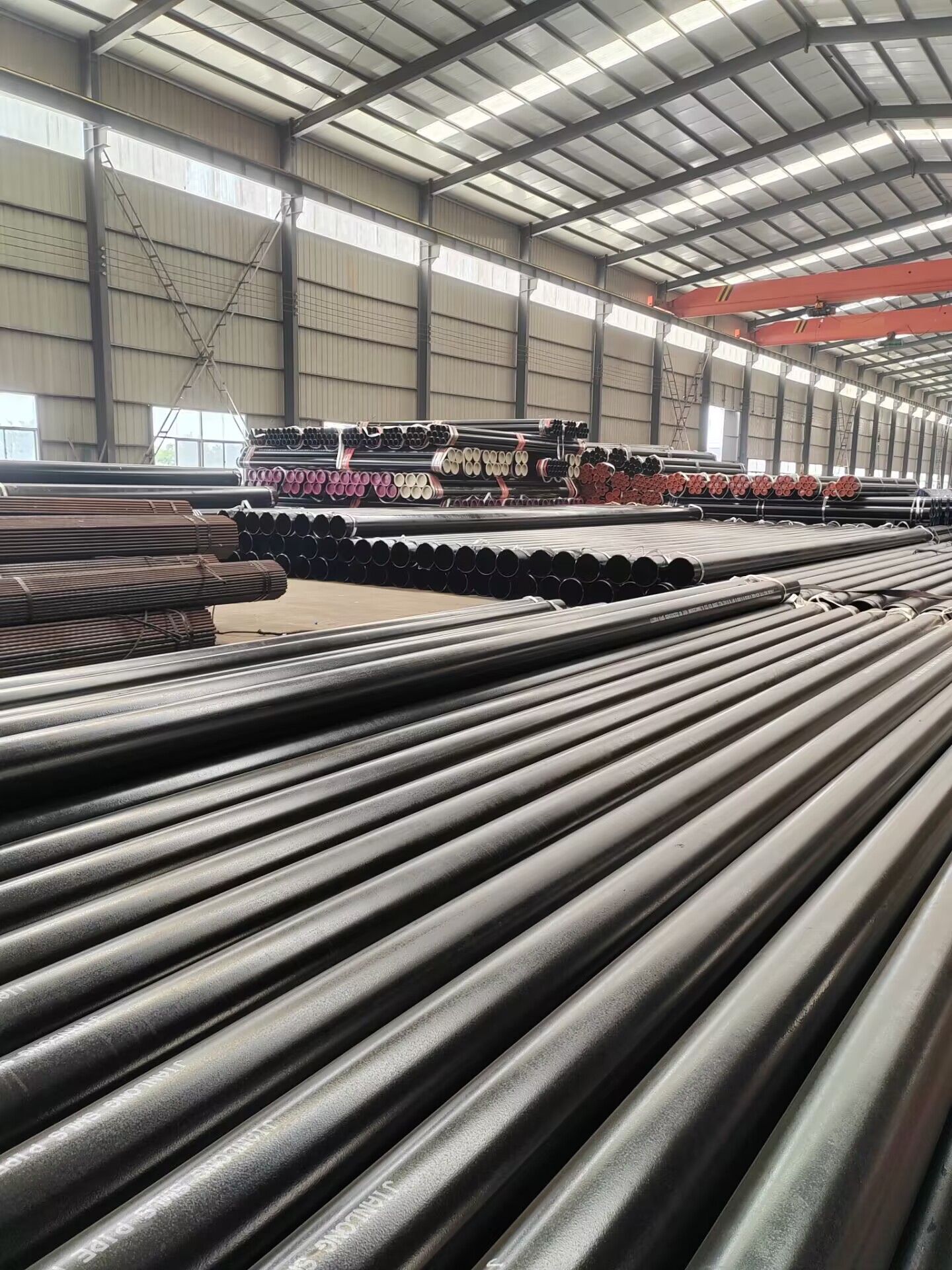

metal tube frameOne of the key benefits of using seamless pipes in industrial applications is their superior strength. The absence of weld seams eliminates weak points in the pipe, making it less susceptible to leaks, cracks, and failures. This increased strength allows seamless pipes to withstand higher pressure and temperature conditions, making them ideal for demanding industrial environments.

Another advantage of seamless pipes is their smooth interior surface. Welded pipes have weld seams that can create turbulence and resistance to flow, which can lead to increased pressure drop and reduced efficiency in fluid transportation systems. Seamless pipes, on the other hand, have a smooth bore that allows for uninterrupted flow of fluids, gases, and other materials. This smooth interior surface also reduces the risk of corrosion and scaling, prolonging the lifespan of the pipe.

In addition to their strength and smooth interior surface, seamless pipes are also more resistant to corrosion and erosion. Welded pipes are more prone to corrosion at the weld seams due to the heat-affected zone created during the welding process. Seamless pipes do not have weld seams, which eliminates this weak point and reduces the risk of corrosion. This makes seamless pipes a more durable and long-lasting option for industrial applications where Corrosion resistance is essential.

https://youtube.com/watch?v=6tUfn1bKo9Y

Seamless pipes are also easier to install and maintain compared to welded pipes. The absence of weld seams eliminates the need for complex welding procedures, reducing the risk of welding defects and ensuring a more secure and reliable connection. Seamless pipes can be easily threaded, bent, and welded using standard techniques, making them versatile and easy to work with in various industrial applications.

Furthermore, seamless pipes offer better dimensional accuracy and tolerances compared to welded pipes. The seamless manufacturing process allows for tighter control over the dimensions and properties of the pipe, ensuring consistent quality and performance. This precision in manufacturing results in seamless pipes that meet the exact specifications and requirements of industrial applications, leading to improved efficiency and reliability.

Overall, the benefits of using seamless pipes in industrial applications are clear. From their superior strength and corrosion resistance to their smooth interior surface and ease of installation, seamless pipes offer numerous advantages that make them a preferred choice for a wide range of industries. Whether used in Oil and gas pipelines, chemical processing plants, power generation facilities, or other industrial settings, seamless pipes provide the durability, reliability, and performance needed to meet the demands of modern industrial applications.