Pros and Cons of Seamless Pipe for Different Applications

When it comes to selecting the right type of pipe for your project, there are several factors to consider. One of the key decisions you will need to make is whether to use seamless, welded, or forged pipe. Each type of pipe has its own set of advantages and disadvantages, and understanding these can help you make an informed decision.

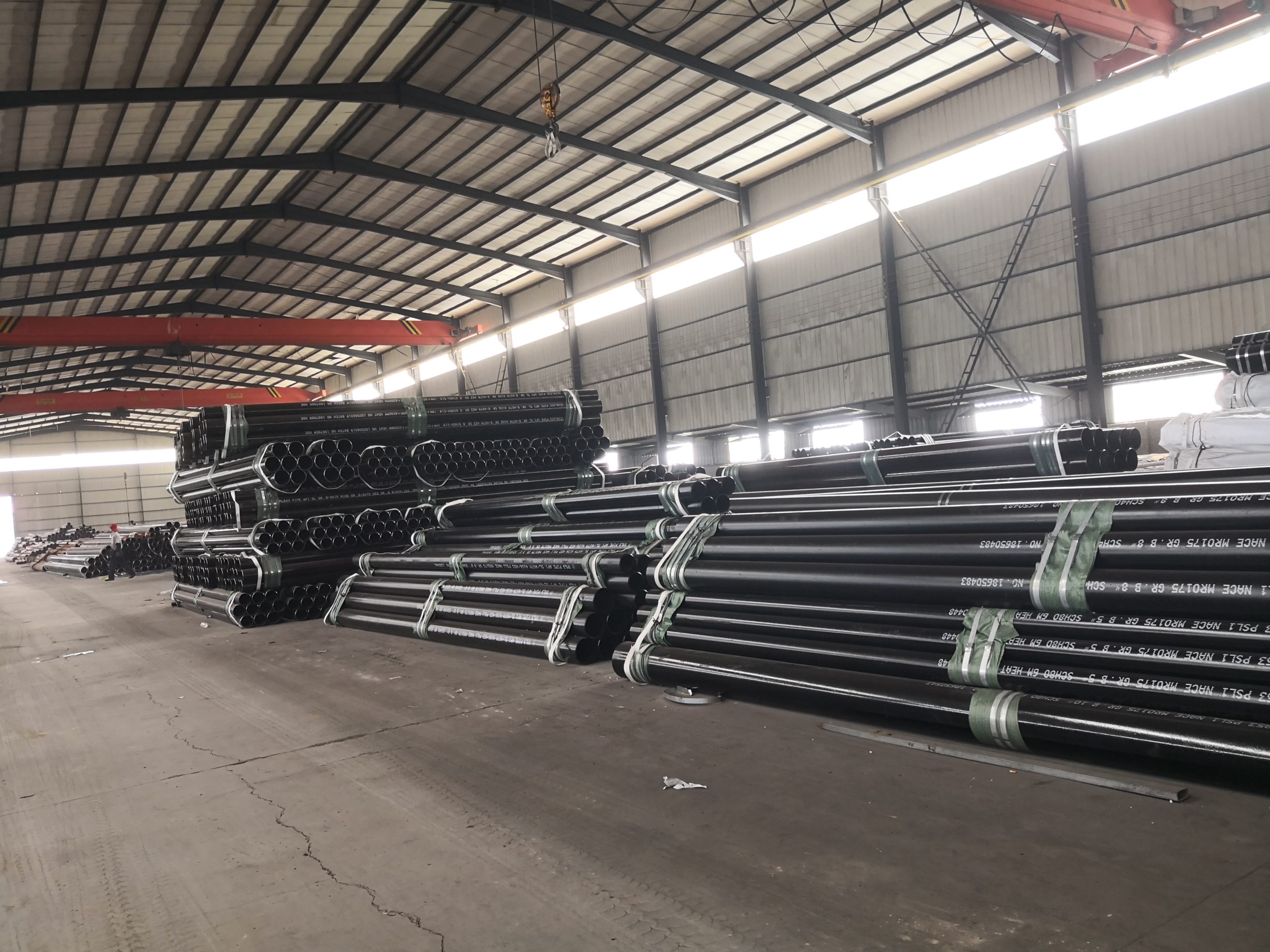

Seamless pipe is made by extruding a solid billet through a die to create a hollow tube. This process results in a pipe with no seams or welds, making it stronger and more reliable than welded pipe. Seamless pipe is also more resistant to corrosion and pressure, making it ideal for high-pressure applications such as Oil and gas pipelines.

One of the main advantages of seamless pipe is its uniformity. Because seamless pipe is made from a single piece of Material, it has a consistent Wall thickness and diameter, which can help improve flow rates and reduce the risk of leaks. Seamless pipe is also easier to inspect for defects, as there are no welds or seams to check for cracks or imperfections.

However, seamless pipe can be more expensive than welded pipe, as the manufacturing process is more complex and time-consuming. Additionally, seamless pipe is limited in size and thickness, which can make it less suitable for larger or thicker applications. Seamless pipe also requires more material to produce, which can increase costs and lead times.

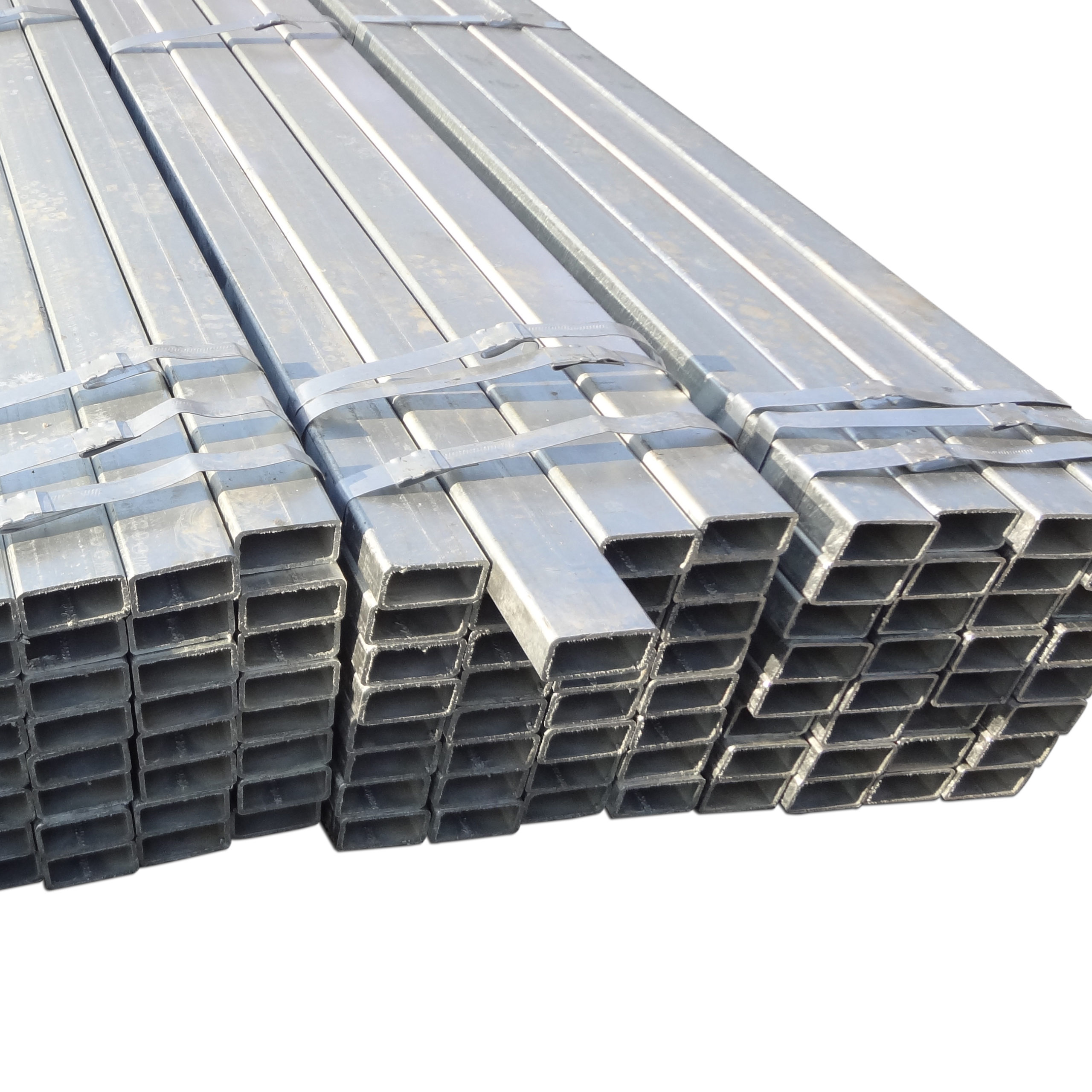

5 8 square Tubing

Despite these drawbacks, seamless pipe is still a popular choice for many applications due to its strength, reliability, and resistance to corrosion. It is commonly used in industries such as oil and gas, petrochemical, and power generation, where high pressure and temperature conditions are present.

In contrast, welded pipe is made by Welding together two pieces of steel to create a seamless joint. Welded pipe is generally less expensive than seamless pipe, making it a cost-effective option for many projects. Welded pipe is also available in a wider range of sizes and thicknesses, making it more versatile for different applications.

However, welded pipe is more prone to defects and corrosion than seamless pipe, as the welding process can weaken the material and create potential weak points. Welded pipe is also more difficult to inspect for defects, as the welds can hide imperfections that may lead to leaks or failures.

Despite these drawbacks, welded pipe is still widely used in a variety of industries, including construction, plumbing, and automotive. Welded pipe is often used in applications where cost is a primary concern, or where the pipe will not be subjected to extreme pressure or temperature conditions.

Forged pipe is made by shaping a solid piece of steel into a hollow tube using heat and pressure. Forged pipe is extremely strong and durable, making it ideal for high-pressure and high-temperature applications. Forged pipe is also resistant to corrosion and wear, making it a long-lasting option for demanding environments.

However, forged pipe is more expensive than seamless or welded pipe, as the manufacturing process is more labor-intensive and requires specialized equipment. Forged pipe is also limited in size and thickness, which can make it less suitable for larger or thicker applications. Additionally, forged pipe is more difficult to produce in large quantities, which can lead to longer lead times and higher costs.

Despite these drawbacks, forged pipe is still a popular choice for applications where strength, durability, and reliability are paramount. Forged pipe is commonly used in industries such as aerospace, defense, and marine, where extreme conditions require a pipe that can withstand high pressure and temperature.

In conclusion, choosing the right type of pipe for your project requires careful consideration of the advantages and disadvantages of seamless, welded, and forged pipe. Each type of pipe has its own unique characteristics that make it suitable for different applications. By understanding the pros and cons of each type of pipe, you can make an informed decision that meets the specific requirements of your project.

Factors to Consider When Choosing Between Welded and Forged Pipe

When it comes to selecting the right type of pipe for your project, there are several factors to consider. One of the most important decisions you will need to make is whether to use seamless, welded, or forged pipe. Each type of pipe has its own unique characteristics and advantages, so it is essential to understand the differences between them before making a decision.

Seamless pipe is made from a solid piece of steel that is heated and then stretched to form a seamless tube. This process results in a pipe that is free of seams, making it ideal for applications where strength and durability are essential. Seamless pipe is also known for its uniformity and consistency, which can help to reduce the risk of leaks or failures in the system.

Welded pipe, on the other hand, is made by welding together two pieces of steel to form a tube. While welded pipe is generally less expensive than seamless pipe, it may not be as strong or durable. Welded pipe is also more prone to corrosion and leaks, as the welding process can create weak points in the pipe. However, welded pipe is often used in applications where cost is a primary concern, such as in plumbing or irrigation systems.

Forged pipe is made by shaping a solid piece of steel into a tube using a forging process. This results in a pipe that is extremely strong and durable, making it ideal for high-pressure or high-temperature applications. Forged pipe is also resistant to corrosion and can withstand harsh environments, making it a popular choice for industries such as oil and gas, chemical processing, and power generation.

When choosing between seamless, welded, or forged pipe, there are several factors to consider. One of the most important considerations is the specific requirements of your project. If you need a pipe that is strong, durable, and resistant to corrosion, forged pipe may be the best option. However, if cost is a primary concern, welded pipe may be a more suitable choice.

Another factor to consider is the size and diameter of the pipe. Seamless pipe is available in a wide range of sizes and diameters, making it suitable for a variety of applications. Welded pipe is also available in a range of sizes, but may be limited in larger diameters. Forged pipe is typically available in smaller sizes, making it ideal for high-pressure applications where strength is essential.

It is also important to consider the material of the pipe when making your decision. Seamless pipe is typically made from Carbon steel, Stainless steel, or Alloy steel, while welded pipe is often made from carbon steel. Forged pipe is usually made from carbon steel or alloy steel, depending on the specific requirements of the project.

In conclusion, when choosing between seamless, welded, or forged pipe, it is essential to consider the specific requirements of your project, as well as factors such as cost, size, diameter, and material. Each type of pipe has its own unique characteristics and advantages, so it is important to carefully evaluate your options before making a decision. By taking the time to research and compare the different types of pipe available, you can ensure that you select the right pipe for your project.