The Advantages of Using Seamless Pipes in Industrial Applications

Seamless Pipes | steel GIANT

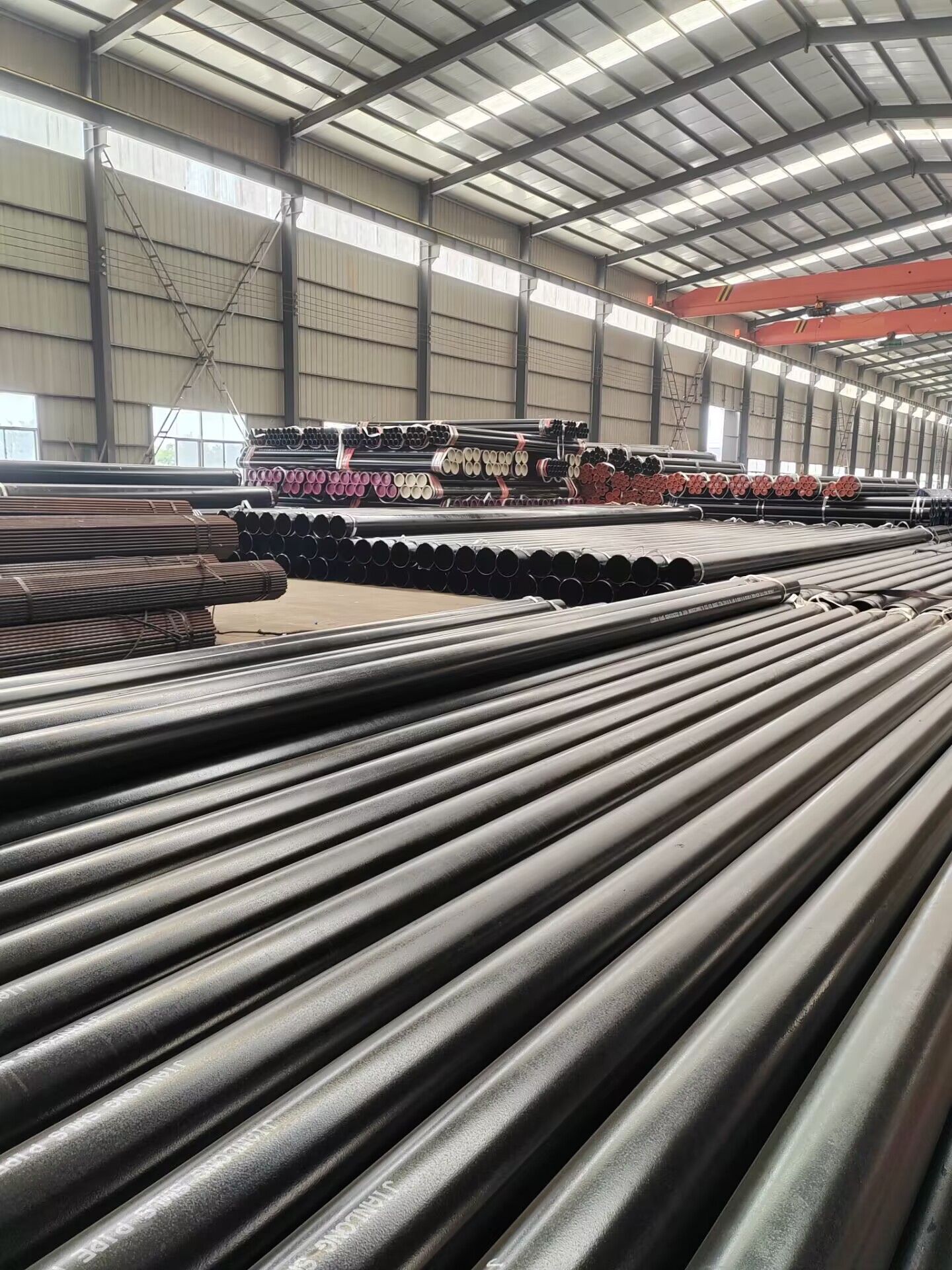

In the realm of industrial applications, the choice of piping Material plays a pivotal role in ensuring efficiency, reliability, and safety. Among the myriad options available, seamless pipes stand out as a preferred choice for many industries. Renowned for their superior quality and performance, seamless pipes offer a range of advantages that make them indispensable in various sectors.

First and foremost, seamless pipes are characterized by their uniformity and consistency in structure. Unlike welded pipes, which are crafted by Welding together multiple sections, seamless pipes are formed from a single piece of steel. This seamless construction eliminates the presence of weak points, such as welded seams, which are susceptible to corrosion and failure over time. As a result, seamless pipes exhibit enhanced durability and reliability, making them ideal for applications that demand utmost strength and longevity.

3 inch Stainless steel Pipe

Moreover, the absence of welded seams in seamless pipes contributes to their superior Mechanical properties. Seamless pipes boast uniform Wall thickness throughout their Length, ensuring optimal performance under high pressure and temperature conditions. This uniformity minimizes the risk of leaks and ruptures, thereby enhancing operational safety in critical industrial processes. Whether conveying fluids, gases, or solids, seamless pipes offer unmatched structural integrity, safeguarding both personnel and equipment against potential hazards.

Furthermore, seamless pipes excel in facilitating smooth and efficient fluid flow. The seamless construction eliminates the internal roughness and irregularities associated with welded seams, thereby reducing frictional resistance within the pipe. This streamlined flow not only enhances energy efficiency but also minimizes pressure drops along the pipeline. Consequently, industries benefit from improved throughput and reduced operating costs, making seamless pipes a cost-effective solution for various fluid transport applications.

Another notable advantage of seamless pipes lies in their versatility and adaptability to diverse operating conditions. Engineered to withstand extreme temperatures, pressures, and corrosive environments, seamless pipes find widespread use across a multitude of industries, including Oil and gas, petrochemical, power generation, automotive, and aerospace. Whether used for conveying hydrocarbons in oil refineries or transporting high-pressure steam in power plants, seamless pipes deliver consistent performance across a spectrum of applications, underscoring their unrivaled versatility and utility.

Moreover, seamless pipes offer inherent aesthetic appeal and ease of installation, further enhancing their appeal in industrial settings. The absence of welded seams lends a sleek and professional appearance to seamless pipelines, reflecting a commitment to quality and precision engineering. Additionally, the seamless construction simplifies installation and maintenance procedures, reducing downtime and labor costs associated with pipe assembly and repairs.

In conclusion, seamless pipes emerge as a cornerstone of modern industrial infrastructure, offering a myriad of advantages that contribute to enhanced performance, reliability, and cost-effectiveness. From their superior durability and mechanical strength to their streamlined fluid flow and versatility, seamless pipes embody the epitome of excellence in piping technology. As industries continue to evolve and innovate, seamless pipes will undoubtedly remain indispensable for meeting the ever-growing demands of complex industrial processes.