Advantages of Seamless steel Pipe in Industrial Applications

Seamless Steel Pipe – Shinestar Steel

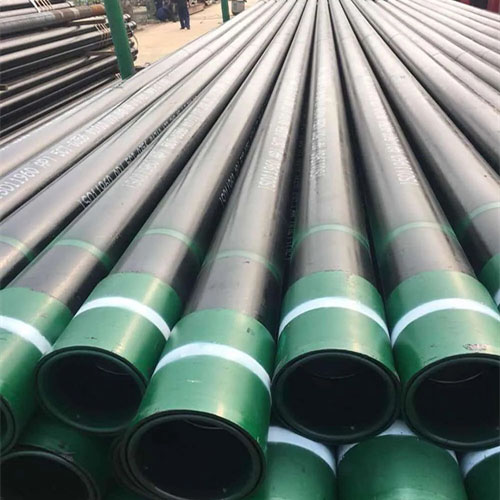

Seamless steel pipes play a crucial role in various industrial applications, offering a range of advantages that contribute to their widespread use. From their exceptional strength and durability to their superior performance under high-pressure conditions, seamless steel pipes have become indispensable components across industries such as Oil and gas, automotive, construction, and manufacturing.

One of the primary advantages of seamless steel pipes lies in their manufacturing process. Unlike welded pipes, which are created by Welding together multiple pieces of steel, seamless pipes are formed from a single cylindrical billet. This seamless construction eliminates the weak points inherent in welded pipes, such as weld seams, which are susceptible to corrosion and failure over time.

Furthermore, the absence of weld seams in seamless steel pipes enhances their structural integrity and resistance to pressure. This makes them ideal for applications that involve transporting fluids or gases at high pressures and temperatures, where the integrity of the pipeline is paramount. Industries such as oil and gas rely heavily on seamless steel pipes for their pipelines, ensuring safe and efficient transportation of valuable resources over long distances.

Another advantage of seamless steel pipes is their uniformity and consistency in dimensions and properties. Because they are manufactured from a single billet, seamless pipes exhibit consistent Wall thickness and diameter throughout their Length. This uniformity ensures tight tolerances, which are crucial in applications where precise dimensions are required, such as machining or threading.

Moreover, seamless steel pipes offer excellent resistance to corrosion, abrasion, and wear, making them suitable for harsh operating environments. Whether exposed to corrosive chemicals, abrasive materials, or extreme temperatures, seamless pipes maintain their structural integrity and performance over time. This Corrosion resistance is particularly valuable in industries such as chemical processing, where exposure to corrosive substances is commonplace.

In addition to their physical properties, seamless steel pipes are highly versatile and adaptable to various fabrication processes. They can be easily cut, bent, and formed to meet specific design requirements, making them ideal for custom applications. Whether used in structural components, machinery, or equipment, seamless pipes offer engineers and designers the flexibility to create innovative solutions tailored to their needs.

Furthermore, seamless steel pipes exhibit superior Mechanical properties compared to other types of piping materials. With high Tensile strength, Yield strength, and impact resistance, seamless pipes can withstand heavy loads and extreme conditions without compromising their structural integrity. This durability ensures reliable performance and longevity, reducing maintenance costs and downtime associated with pipe failures.

In conclusion, seamless steel pipes offer numerous advantages that make them indispensable in industrial applications. From their seamless construction and uniformity to their resistance to corrosion and versatility, seamless pipes provide a reliable solution for transporting fluids and gases in various industries. As technology advances and demand for high-performance materials grows, seamless steel pipes will continue to play a vital role in shaping the future of industrial infrastructure.

A Comprehensive Guide to Understanding Shinestar Steel’s Seamless Steel Pipe Solutions

Seamless Steel Pipe – Shinestar Steel

When it comes to industrial applications requiring strength, durability, and reliability, seamless steel pipes stand out as one of the most crucial components. Whether it’s for transporting fluids, gas, or solids, the seamless steel pipe plays a vital role in various sectors, including oil and gas, petrochemicals, construction, automotive, and more. Understanding the importance of quality and precision in seamless steel pipe manufacturing, companies like Shinestar Steel have emerged as leaders in providing comprehensive solutions tailored to meet diverse industrial needs.

Shinestar Steel, a renowned name in the steel industry, has garnered a reputation for excellence in producing seamless steel pipes of superior quality. With a commitment to innovation, technological advancement, and stringent quality control measures, Shinestar Steel has positioned itself as a trusted partner for industries worldwide.

One of the primary advantages of seamless steel pipes lies in their inherent strength and uniformity. Unlike welded pipes, seamless pipes are manufactured without any seams or joints, ensuring enhanced structural integrity and resistance to pressure and corrosion. This makes them ideal for applications where reliability and safety are paramount, such as in the transportation of hazardous substances or in high-pressure environments.

https://youtube.com/watch?v=6tUfn1bKo9Y

Moreover, Shinestar Steel’s seamless steel pipes are engineered to meet the most stringent industry standards, ensuring compliance with specifications and regulations set forth by organizations such as the American Petroleum Institute ( API), the American Society for Testing and Materials (ASTM), and the International Organization for Standardization (ISO). This dedication to quality assurance not only instills confidence in the product but also ensures optimal performance and longevity in various operational conditions.

In addition to their superior strength and quality, Shinestar Steel’s seamless steel pipes offer unparalleled versatility and customization options. With a wide range of sizes, grades, and specifications available, customers can find the perfect seamless pipe solution to suit their specific requirements. Whether it’s for high-temperature applications, corrosive environments, or structural purposes, Shinestar Steel’s seamless steel pipes are designed to deliver exceptional performance and reliability.

Furthermore, Shinestar Steel employs state-of-the-art manufacturing processes and cutting-edge technology to produce seamless steel pipes with precise dimensional accuracy and surface finish. Through techniques such as Hot rolling, cold drawing, and thermal treatments, Shinestar Steel ensures that each seamless pipe meets the highest standards of quality and consistency.

The seamless steel pipe manufacturing process begins with the selection of premium quality raw materials, including carefully sourced steel billets or ingots. These materials undergo rigorous inspection and testing to verify their mechanical properties, chemical composition, and purity. Once approved, the raw materials are then heated to the appropriate temperature and formed into hollow cylindrical shapes through a series of rolling or extrusion processes.

Subsequently, the seamless pipes undergo various finishing operations, such as heat treatment, sizing, straightening, and inspection, to ensure they meet the specified requirements for strength, dimensions, and surface quality. Finally, the seamless steel pipes are subjected to comprehensive testing procedures, including Non-destructive testing (NDT) methods such as Ultrasonic testing, radiographic testing, and hydrostatic testing, to verify their integrity and performance.

3 inch mild steel pipe

In conclusion, Shinestar Steel’s seamless steel pipes represent the epitome of quality, reliability, and performance in the industry. With a steadfast commitment to excellence and customer satisfaction, Shinestar Steel continues to set the benchmark for seamless pipe manufacturing, providing tailored solutions to meet the evolving needs of industries worldwide. Whether it’s for critical infrastructure projects, industrial applications, or commercial ventures, Shinestar Steel’s seamless steel pipes offer the assurance of uncompromising quality and seamless performance.