Pros and Cons of Seamless steel Pipe

Seamless Steel Pipe Vs. Welded steel pipe

When it comes to selecting the right type of steel pipe for various applications, the choice between seamless and welded steel pipes is a critical consideration. Each type has its own set of advantages and disadvantages, which can significantly impact the performance and cost-effectiveness of the project. In this article, we will delve into the pros and cons of seamless steel pipes, offering insights into why they are favored in certain scenarios.

Seamless steel pipes, as the name suggests, are manufactured without any Welding seam or joint. This seamless construction is achieved through a process known as extrusion or rotary piercing, where a solid steel billet is heated and pushed or pierced through a die to form a hollow cylindrical shape. One of the primary advantages of seamless steel pipes lies in their superior strength and reliability. Without the presence of weld seams, seamless pipes exhibit uniformity in structure and consistency in Mechanical properties, making them ideal for high-pressure applications and critical infrastructure projects.

Furthermore, the absence of weld seams eliminates the risk of weak points or defects that could compromise the integrity of the pipe. This inherent strength and reliability make seamless steel pipes well-suited for conveying fluids, gases, and chemicals in industries such as Oil and gas, petrochemicals, and power generation. In addition to their structural integrity, seamless pipes offer enhanced Corrosion resistance due to their homogeneous composition and smooth surface finish, reducing the likelihood of corrosion-induced failures and prolonging the service life of the pipeline.

Another notable advantage of seamless steel pipes is their superior dimensional accuracy and precision. Unlike welded pipes, which may undergo deformation or distortion during the welding process, seamless pipes maintain tight tolerances and consistent dimensions, ensuring compatibility with various fittings and connectors. This precision is particularly crucial in applications where tight seals and proper alignment are essential, such as in hydraulic systems, automotive manufacturing, and aerospace engineering.

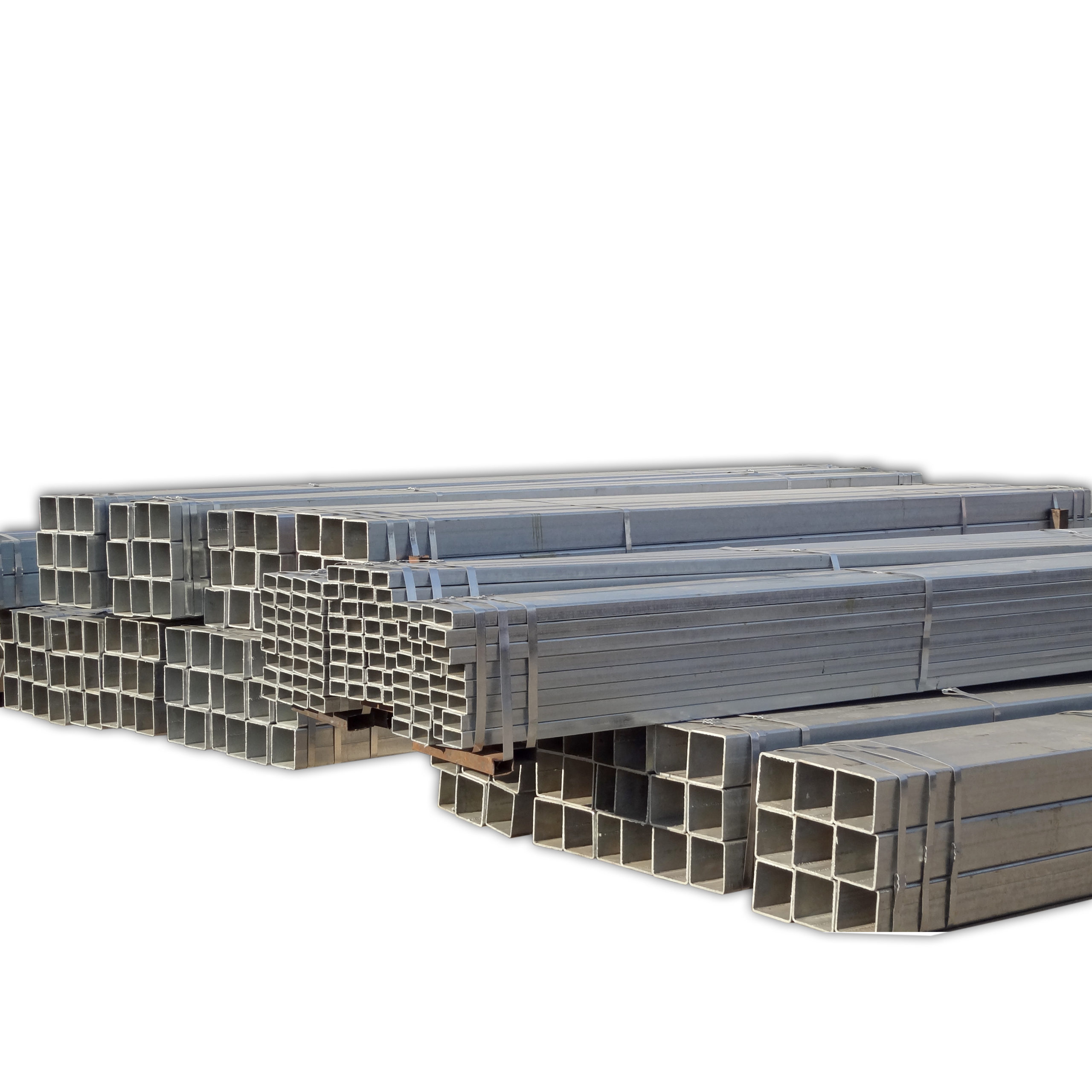

square tube 2×2 priceMoreover, seamless steel pipes are renowned for their aesthetic appeal and clean appearance. The absence of weld seams results in a smooth, uninterrupted surface that is visually appealing and conducive to painting, coating, or other surface treatments. This aesthetic quality is valued in architectural and decorative applications where the pipe may be exposed to view or incorporated into design elements.

However, despite their numerous advantages, seamless steel pipes also have some limitations that must be considered. One of the main drawbacks is the higher production cost associated with the manufacturing process. The extrusion or rotary piercing method used to produce seamless pipes requires specialized equipment and processes, leading to increased production expenses compared to welded pipes. As a result, seamless steel pipes tend to be more expensive upfront, which can impact the overall project budget.

Additionally, seamless steel pipes may have longer lead times and limited availability compared to welded pipes, especially for large diameters or custom specifications. The complex manufacturing process and higher production costs can result in longer production cycles and supply constraints, which may affect project timelines and scheduling.

In conclusion, seamless steel pipes offer a host of advantages in terms of strength, reliability, corrosion resistance, dimensional accuracy, and aesthetics. These qualities make them the preferred choice for demanding applications where performance and durability are paramount. However, the higher production cost and potential supply constraints should be carefully weighed against the specific requirements and budgetary constraints of the project. Ultimately, the decision between seamless and welded steel pipes depends on a thorough assessment of the pros and cons, as well as the unique needs of the application.