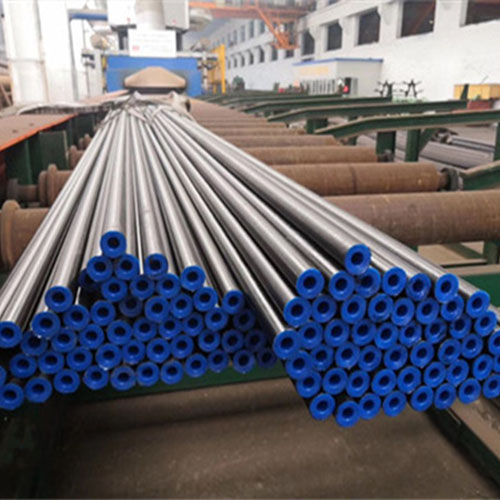

Benefits of Using Carbon steel Welded Pipe in Industrial Applications

Carbon steel welded and Seamless pipes are essential components in various industrial applications, offering a range of benefits that make them highly desirable for use. In industries spanning from construction to manufacturing, the choice of pipe Material can significantly impact performance, durability, and overall efficiency. Here, we delve into the advantages of utilizing carbon steel welded pipes in industrial settings.

Firstly, carbon steel welded pipes are renowned for their strength and durability. These pipes are constructed from a combination of carbon and iron, offering exceptional Tensile strength and resistance to deformation under high pressure or stress. This inherent strength makes carbon steel pipes ideal for conveying fluids and gases in demanding industrial environments where reliability is paramount.

Moreover, carbon steel welded pipes boast excellent Corrosion resistance, particularly when compared to other materials such as Stainless steel. This resistance to corrosion is crucial in industrial applications where pipes may be exposed to harsh chemicals, moisture, or extreme temperatures. By minimizing the risk of corrosion and rust formation, carbon steel pipes can maintain their structural integrity over prolonged periods, reducing the need for frequent maintenance and replacement.

Another significant advantage of carbon steel welded pipes is their versatility and adaptability to various fabrication processes. These pipes can be easily welded, bent, and formed to meet specific requirements, allowing for seamless integration into complex industrial systems. Whether used in pipelines, structural frameworks, or machinery components, carbon steel welded pipes offer unmatched flexibility, enabling engineers and designers to achieve precise configurations tailored to their applications.

Furthermore, carbon steel welded pipes are cost-effective solutions for industrial piping needs. Compared to alternative materials such as stainless steel or alloy pipes, carbon steel pipes are generally more affordable while still delivering comparable performance and longevity. This affordability makes carbon steel pipes an attractive option for budget-conscious projects without compromising on quality or reliability.

In addition to their Mechanical properties, carbon steel welded pipes are also environmentally friendly choices for industrial applications. Unlike plastic pipes, which can pose disposal challenges and environmental risks, carbon steel pipes are fully recyclable and can be repurposed at the end of their service life. By choosing carbon steel pipes, industries can minimize their environmental footprint and contribute to sustainable resource management practices.

Moreover, carbon steel welded pipes offer superior thermal conductivity, making them ideal for applications involving heat transfer or thermal management. Whether used in HVAC systems, heat exchangers, or steam pipelines, carbon steel pipes facilitate efficient heat exchange processes, enhancing overall system performance and energy efficiency.

Lastly, carbon steel welded pipes are readily available in a wide range of sizes, diameters, and thicknesses to suit diverse industrial requirements. This accessibility ensures that businesses can procure the necessary piping materials promptly, minimizing project lead times and downtime. Additionally, advancements in manufacturing technologies have further streamlined the production of carbon steel welded pipes, resulting in consistent quality and dimensional accuracy across the product range.

In conclusion, the benefits of using carbon steel welded pipes in industrial applications are manifold. From their exceptional strength and corrosion resistance to their cost-effectiveness and environmental sustainability, carbon steel pipes offer a compelling solution for various piping needs. As industries continue to evolve and innovate, the enduring appeal of carbon steel welded pipes remains undiminished, underscoring their enduring value in modern industrial processes.

Key Differences Between Carbon Steel Welded and Seamless Pipes

Carbon steel pipes are widely used in various industries due to their durability, strength, and affordability. Within the realm of carbon steel pipes, there are two primary types: welded and seamless. While both serve similar purposes, they have distinct differences that affect their performance and suitability for specific applications.

To begin with, let’s explore the manufacturing process of each type. Welded carbon steel pipes are crafted by Welding together steel plates or coils, forming a cylindrical shape. This process involves the use of heat and pressure to fuse the materials together. In contrast, seamless carbon steel pipes are created from solid round steel billets, which are heated and pierced to form a hollow tube. This process eliminates the need for welding, resulting in a smooth interior surface.

One of the key differences between welded and seamless carbon steel pipes lies in their structural integrity. Seamless pipes have a consistent, uniform composition throughout, with no welded seams that could potentially weaken the material. This makes seamless pipes particularly suitable for applications requiring high pressure or temperature resistance, as they are less prone to leakage or failure.

Furthermore, the absence of welded seams in seamless pipes contributes to their improved corrosion resistance. Welded pipes are more susceptible to corrosion at the weld seam due to the presence of heat-affected zones and potential defects in the weld. In contrast, seamless pipes exhibit better corrosion resistance, making them ideal for environments where exposure to corrosive substances is a concern.

Another significant factor to consider is the dimensional accuracy of the pipes. Seamless carbon steel pipes typically have tighter tolerances and smoother surfaces compared to welded pipes. This superior dimensional accuracy makes seamless pipes the preferred choice for applications that demand precise measurements and a high-quality finish.

telescoping steel square tubingCost is also a crucial consideration when choosing between welded and seamless carbon steel pipes. Generally, welded pipes are more economical to manufacture and purchase than seamless pipes. The welding process allows for greater flexibility in production, resulting in lower production costs. However, it’s essential to weigh this cost advantage against the potential drawbacks of welded pipes in terms of structural integrity and corrosion resistance.

In terms of availability and variety, welded carbon steel pipes have a slight edge over seamless pipes. Welded pipes are produced in a wider range of sizes and thicknesses, making them more readily available for various industrial applications. Additionally, welded pipes can be fabricated to custom lengths and configurations, offering greater flexibility in design and installation.

In conclusion, while both welded and seamless carbon steel pipes have their advantages and disadvantages, the choice between the two ultimately depends on the specific requirements of the application. Welded pipes offer cost savings and versatility in terms of size and configuration, while seamless pipes provide superior structural integrity, corrosion resistance, and dimensional accuracy. By understanding the key differences between these two types of pipes, engineers and decision-makers can make informed choices to ensure optimal performance and longevity in their projects.