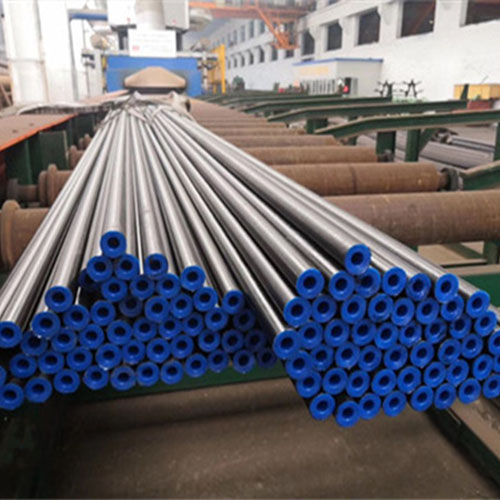

Benefits of Using Seamless steel Round Tubing in Industrial Applications

Seamless steel round tubing is a versatile and durable Material that is commonly used in a wide range of industrial applications. Its seamless construction provides numerous benefits that make it a popular choice for engineers and manufacturers alike.

One of the key advantages of seamless steel round tubing is its superior strength and durability. Unlike welded tubing, which has a seam that can weaken the overall structure, seamless tubing is made from a single piece of steel, making it more resistant to pressure, bending, and cracking. This makes it ideal for applications where strength and reliability are paramount, such as in the construction of heavy machinery, pipelines, and structural supports.

In addition to its strength, seamless steel round tubing also offers excellent Corrosion resistance. The seamless construction eliminates the need for Welding, which can create weak points in the material that are susceptible to corrosion. This makes seamless tubing a great choice for applications where exposure to harsh chemicals, moisture, or extreme temperatures is a concern. Whether used in the Oil and gas industry, chemical processing plants, or marine environments, seamless steel round tubing can withstand the elements and maintain its integrity over time.

Another benefit of seamless steel round tubing is its uniformity and consistency. Because it is manufactured using a continuous extrusion process, seamless tubing has a smooth and uniform surface that is free of imperfections. This ensures a tight fit when connecting multiple pieces of tubing together, reducing the risk of leaks or failures in the system. Additionally, the consistent dimensions of seamless tubing make it easier to work with and install, saving time and labor costs during the manufacturing process.

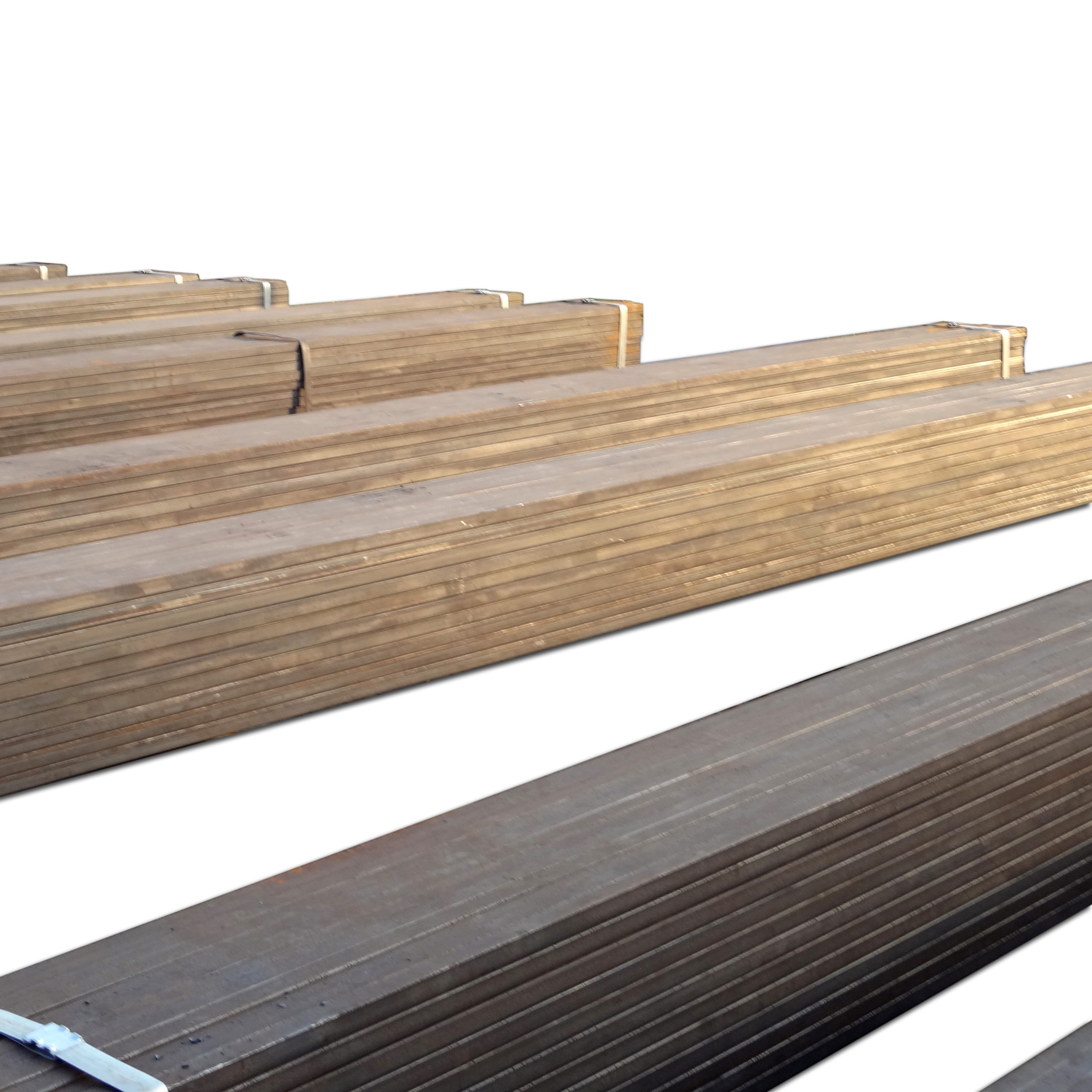

2×2 square tubing galvanized

Furthermore, seamless steel round tubing offers excellent machinability and weldability. Its uniform composition and smooth surface make it easy to cut, shape, and weld, allowing for precise customization to meet specific project requirements. Whether you need to create complex bends, angles, or connections, seamless tubing can be easily manipulated without compromising its structural integrity. This versatility makes it a valuable material for a wide range of applications, from automotive components to architectural structures.

In conclusion, seamless steel round tubing is a reliable and cost-effective solution for a variety of industrial applications. Its superior strength, corrosion resistance, uniformity, and machinability make it a preferred choice for engineers and manufacturers looking for a durable and versatile material. Whether used in heavy machinery, chemical processing plants, or structural supports, seamless tubing provides the performance and reliability needed to withstand the demands of modern industry. Consider seamless steel round tubing for your next project and experience the benefits firsthand.

How to Choose the Right Seamless Steel Round Tubing for Your Project

When it comes to selecting the right seamless steel round tubing for your project, there are several factors to consider in order to ensure that you are choosing the best option for your specific needs. Seamless steel round tubing is a versatile and durable material that is commonly used in a wide range of industries, including construction, automotive, and manufacturing. Its seamless construction provides a smooth interior surface, making it ideal for applications where strength and precision are essential.

One of the first things to consider when choosing seamless steel round tubing is the material grade. Steel tubing is available in a variety of grades, each with its own unique properties and characteristics. The grade of steel you choose will depend on the specific requirements of your project, such as strength, corrosion resistance, and weldability. Common grades of seamless steel round tubing include ASTM A519, ASTM A106, and ASTM A53, among others. It is important to consult with a knowledgeable supplier or engineer to determine the best grade of steel tubing for your project.

In addition to material grade, it is also important to consider the size and dimensions of the seamless steel round tubing. Tubing is available in a wide range of sizes, from small diameters for precision applications to larger diameters for structural support. The Wall thickness of the tubing is another important consideration, as it will impact the strength and durability of the material. It is essential to carefully measure and calculate the required dimensions for your project to ensure that you are selecting the right size of tubing.

Another important factor to consider when choosing seamless steel round tubing is the surface finish. Seamless steel tubing is available in a variety of finishes, including hot rolled, Cold drawn, and polished. The surface finish of the tubing will impact its appearance, as well as its corrosion resistance and durability. For applications where a smooth and polished surface is required, such as in the food and beverage industry, a polished finish may be the best option. On the other hand, for applications where strength and durability are more important, a hot rolled or cold drawn finish may be more suitable.

When selecting seamless steel round tubing for your project, it is also important to consider the manufacturing process. Seamless tubing is produced by piercing a solid billet of steel to create a hollow tube, which is then drawn or rolled to the desired dimensions. The seamless construction of the tubing provides a high level of strength and precision, making it ideal for applications where reliability is essential. It is important to choose a reputable supplier with a proven track record of producing high-quality seamless steel tubing to ensure that you are getting a reliable and durable product for your project.

In conclusion, choosing the right seamless steel round tubing for your project requires careful consideration of several factors, including material grade, size and dimensions, surface finish, and manufacturing process. By taking the time to evaluate these factors and consult with a knowledgeable supplier or engineer, you can ensure that you are selecting the best option for your specific needs. Seamless steel round tubing is a versatile and durable material that is well-suited for a wide range of applications, making it an excellent choice for your next project.