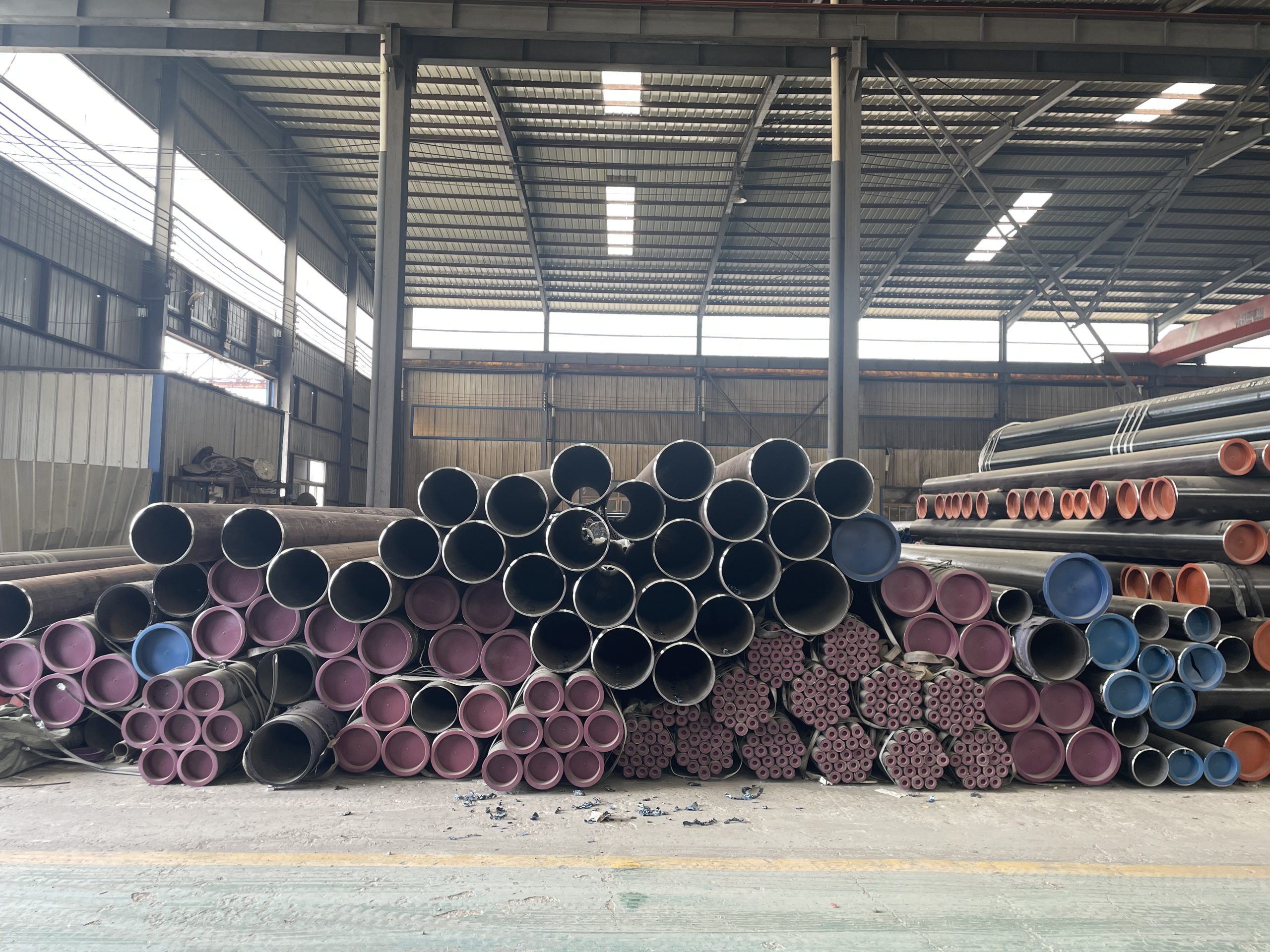

The Differences Between Welded and Seamless steel Pipes

Steel pipes are a crucial component in various industries, including construction, Oil and gas, and manufacturing. When it comes to steel pipes, there are two main types: welded and seamless. Both types have their own unique characteristics and applications, making it important to understand the differences between them.

Welded steel pipes are made by Welding a steel plate or coil into a cylindrical shape. The welding process involves heating the edges of the steel plate or coil and then pressing them together to form a seamless joint. This process creates a strong and durable Pipe that is suitable for a wide range of applications. Welded steel pipes are commonly used in structural applications, such as building construction and infrastructure projects.

On the other hand, seamless steel pipes are made by piercing a solid steel billet to create a hollow tube. This process eliminates the need for welding, resulting in a pipe with a smooth and uniform surface. Seamless steel pipes are known for their high strength and reliability, making them ideal for high-pressure and high-temperature applications. These pipes are commonly used in the oil and gas industry, as well as in the automotive and aerospace sectors.

One of the main differences between welded and seamless steel pipes is their manufacturing process. Welded pipes are made by welding steel plates or coils together, while seamless pipes are made by piercing a solid steel billet. This difference in manufacturing process affects the overall quality and performance of the pipes. Welded pipes may have weld seams that can weaken the pipe, while seamless pipes have a uniform structure that provides better strength and reliability.

1 od steel Tubing

Another key difference between welded and seamless steel pipes is their cost. Welded pipes are generally less expensive to produce than seamless pipes, making them a more cost-effective option for certain applications. However, seamless pipes are often preferred for high-pressure and high-temperature applications due to their superior strength and reliability. The cost difference between welded and seamless pipes can vary depending on the size, grade, and specifications of the pipe.

In terms of performance, seamless steel pipes are generally considered to be superior to welded pipes. Seamless pipes have a uniform structure that provides better strength and reliability, making them ideal for demanding applications. Welded pipes, on the other hand, may have weld seams that can weaken the pipe and make it more susceptible to leaks and failures. For this reason, seamless pipes are often preferred for critical applications where performance and reliability are paramount.

In conclusion, both welded and seamless steel pipes have their own unique characteristics and applications. Welded pipes are cost-effective and suitable for a wide range of applications, while seamless pipes are known for their superior strength and reliability. Understanding the differences between these two types of steel pipes is essential for choosing the right pipe for your specific needs. Whether you need a pipe for a structural project or a high-pressure application, knowing the differences between welded and seamless steel pipes will help you make an informed decision.