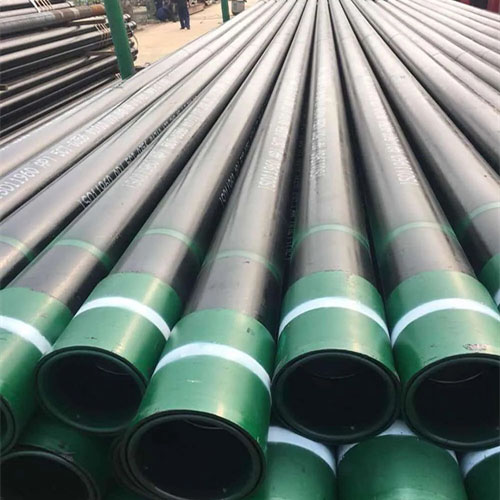

Benefits of Using Seamless steel Pipe/Tube in Industrial Applications

Seamless steel pipes and tubes are essential components in various industrial applications due to their numerous benefits. These pipes are manufactured without any Welding seam, which makes them stronger and more reliable than welded pipes. The seamless construction also ensures a smooth interior surface, which reduces friction and allows for efficient fluid flow. In this article, we will explore the advantages of using seamless steel pipes and tubes in industrial settings.

One of the primary benefits of seamless steel pipes is their superior strength. The absence of a weld seam eliminates the weak points that are often found in welded pipes, making seamless pipes more resistant to pressure and stress. This strength is crucial in industrial applications where pipes are subjected to high temperatures, pressures, and corrosive environments. Seamless steel pipes are also more durable and have a longer lifespan compared to welded pipes, reducing the need for frequent replacements and maintenance.

Another advantage of seamless steel pipes is their uniformity in shape and size. Seamless pipes are manufactured using a process called extrusion, which ensures consistent dimensions and Wall thickness throughout the Length of the pipe. This uniformity is essential in industrial applications where precise measurements are required for proper fitting and installation. Seamless pipes also have a higher tolerance for bending and deformation, making them ideal for complex piping systems that require flexibility and durability.

In addition to their strength and uniformity, seamless steel pipes offer excellent Corrosion resistance. The smooth interior surface of seamless pipes prevents the accumulation of rust and other contaminants, which can degrade the pipe over time. This corrosion resistance is essential in industrial applications where pipes are exposed to harsh chemicals, acids, and other corrosive substances. Seamless steel pipes are also resistant to high temperatures, making them suitable for applications that involve extreme heat or thermal cycling.

Furthermore, seamless steel pipes are known for their high performance in terms of fluid flow. The absence of a weld seam reduces turbulence and friction inside the pipe, allowing for smooth and efficient flow of liquids, gases, and other substances. This improved flow rate is crucial in industrial processes where the speed and consistency of fluid transport are essential. Seamless pipes also have a lower risk of leaks and failures compared to welded pipes, ensuring reliable operation in critical applications.

1020 dom Tubing

Overall, seamless steel pipes and tubes offer a wide range of benefits that make them indispensable in various industrial applications. From their superior strength and durability to their uniformity in shape and size, seamless pipes provide a reliable and efficient solution for fluid transport and containment. Their corrosion resistance and high performance in fluid flow make them ideal for demanding environments where reliability and efficiency are paramount. In conclusion, seamless steel pipes are a versatile and cost-effective choice for industrial piping systems that require strength, durability, and performance.