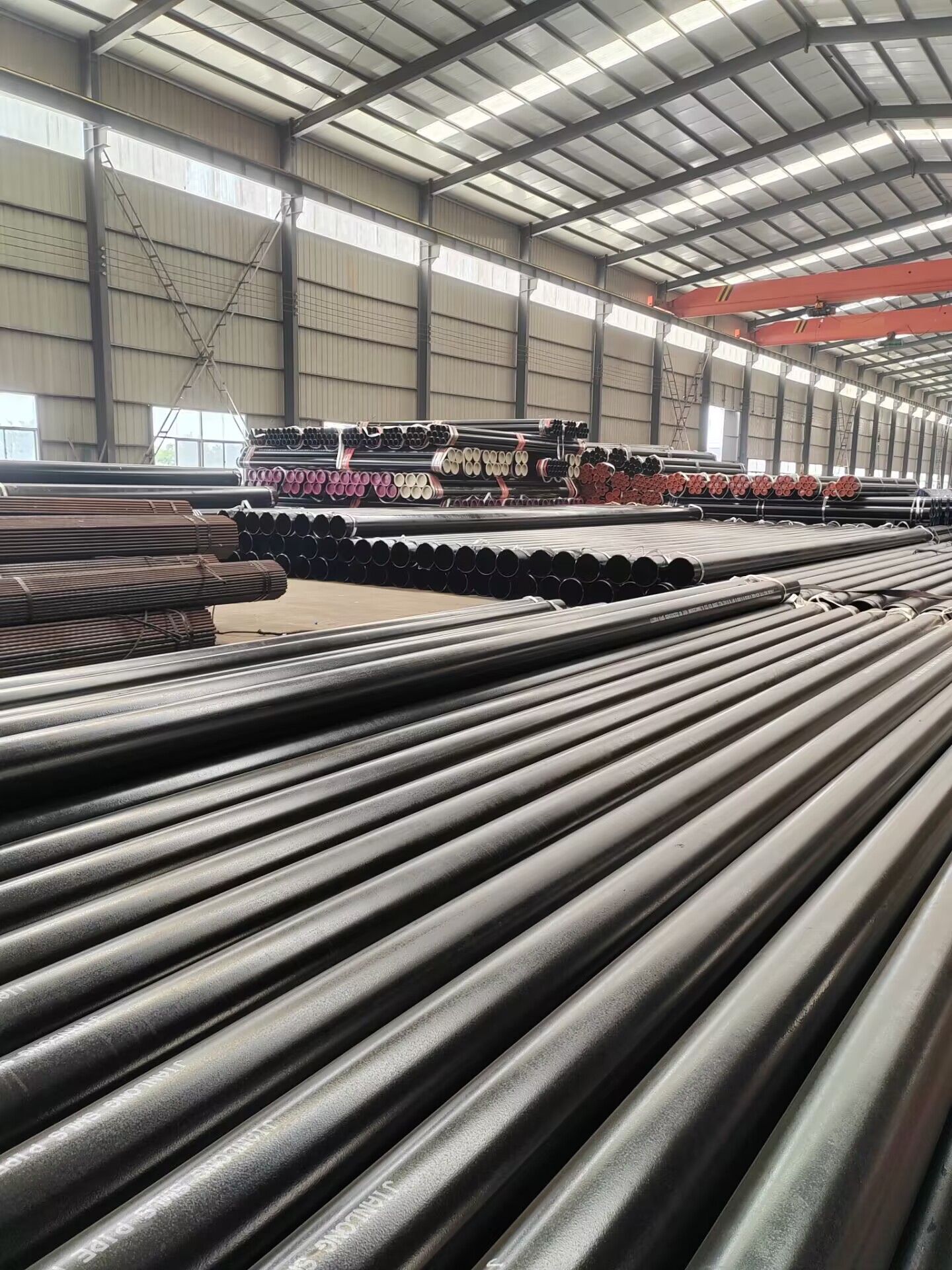

Advantages of Using Seamless steel Pipe in Industrial Applications

Seamless steel pipe is a type of steel pipe that is manufactured without any Welding seam or joint. This means that the pipe is made from a solid piece of steel, which results in a smooth and uniform surface. Seamless steel pipe is commonly used in a variety of industrial applications due to its many advantages over other types of steel pipe.

One of the main advantages of using seamless steel pipe is its strength and durability. Because seamless steel pipe is made from a single piece of steel, it is able to withstand high pressure and temperature conditions without the risk of leaks or failures. This makes seamless steel pipe ideal for use in industries such as Oil and gas, petrochemical, and power generation, where reliability and safety are paramount.

Another advantage of seamless steel pipe is its uniformity and consistency. Because seamless steel pipe is manufactured without any welding seams or joints, it has a smooth and even surface that allows for better flow of fluids and gases. This can help to reduce friction and turbulence within the pipe, resulting in improved efficiency and performance.

In addition to its strength and uniformity, seamless steel pipe is also highly resistant to corrosion and rust. This is due to the fact that seamless steel pipe is made from high-quality steel that has been treated with protective coatings to prevent oxidation and deterioration. This makes seamless steel pipe ideal for use in harsh environments where exposure to corrosive substances is common.

Furthermore, seamless steel pipe is easy to install and maintain. Because seamless steel pipe is manufactured in a variety of sizes and lengths, it can be easily customized to fit the specific needs of a project. This can help to reduce waste and minimize the need for additional fittings or connectors. Additionally, seamless steel pipe requires minimal maintenance and upkeep, making it a cost-effective and efficient choice for industrial applications.

Overall, seamless steel pipe offers a number of advantages over other types of steel pipe, including its strength, durability, uniformity, Corrosion resistance, and ease of installation. These qualities make seamless steel pipe an ideal choice for a wide range of industrial applications, from transporting fluids and gases to supporting structural components. Whether you are working in the oil and gas industry, petrochemical industry, or power generation industry, seamless steel pipe can provide the reliability and performance you need to get the job done.

Key Differences Between Seamless Steel Pipe and Welded steel pipe

Steel pipes are an essential component in various industries, including construction, oil and gas, and manufacturing. When it comes to steel pipes, there are two main types: seamless steel pipe and welded steel pipe. While both serve the same purpose of transporting fluids or gases, there are key differences between the two that are important to understand.

3 8 metal Tubing

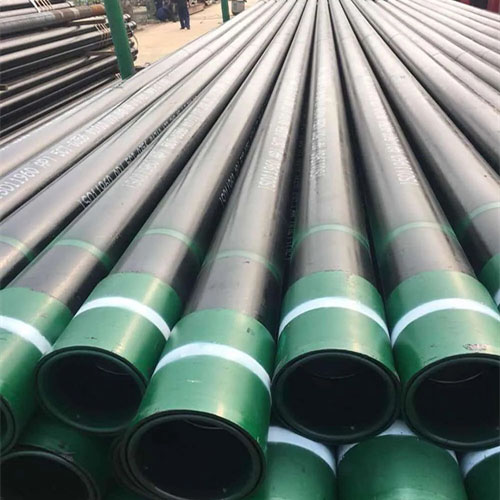

Seamless steel pipes are made from a solid round steel billet that is heated and pierced to create a hollow tube. This process results in a pipe with no seams or welds, hence the name “seamless.” The lack of seams in seamless steel pipes makes them stronger and more reliable than welded steel pipes. Seamless pipes are also more uniform in shape and size, which allows for easier installation and a more aesthetically pleasing finished product.

On the other hand, welded steel pipes are made by rolling a flat steel plate into a tube and welding the edges together. This process creates a seam along the Length of the pipe, which can be a weak point in the structure. Welded pipes are generally less expensive to produce than seamless pipes, making them a popular choice for applications where cost is a primary concern. However, the presence of a seam in welded pipes can make them more susceptible to leaks and failures over time.

One of the main advantages of seamless steel pipes is their superior strength and durability. Because seamless pipes are made from a single piece of steel, they are able to withstand higher pressure and temperature levels than welded pipes. This makes seamless pipes ideal for applications where reliability and performance are critical, such as in the oil and gas industry or in high-pressure hydraulic systems.

Another key difference between seamless and welded steel pipes is their appearance. Seamless pipes have a smooth, polished surface that is free of any visible seams or welds. This makes seamless pipes more visually appealing and easier to clean than welded pipes, which can have rough, uneven surfaces due to the welding process. In addition, the lack of seams in seamless pipes reduces the risk of corrosion and rust, extending the lifespan of the pipe.

In terms of installation, seamless steel pipes are generally easier to work with than welded pipes. Because seamless pipes are more uniform in shape and size, they can be easily connected using couplings or fittings without the need for additional welding. This can save time and labor costs during the installation process, making seamless pipes a more efficient choice for many applications.

In conclusion, seamless steel pipes offer several advantages over welded steel pipes, including superior strength, durability, and appearance. While welded pipes may be more cost-effective in some cases, the potential for leaks and failures due to the presence of seams makes seamless pipes a more reliable option for critical applications. Whether you are in the construction, oil and gas, or manufacturing industry, choosing the right type of steel pipe is essential for ensuring the success and longevity of your project.