Exploring the Benefits of ASTM A106 GR.B Seamless steel Pipe

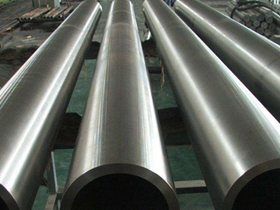

ASTM A106 GR.B Seamless Steel Pipe is a versatile and cost-effective choice for a wide range of applications. This type of steel pipe is made from a solid round steel billet, which is heated and then extruded to create a hollow tube. The seamless steel pipe is then formed into a variety of shapes and sizes, depending on the application.

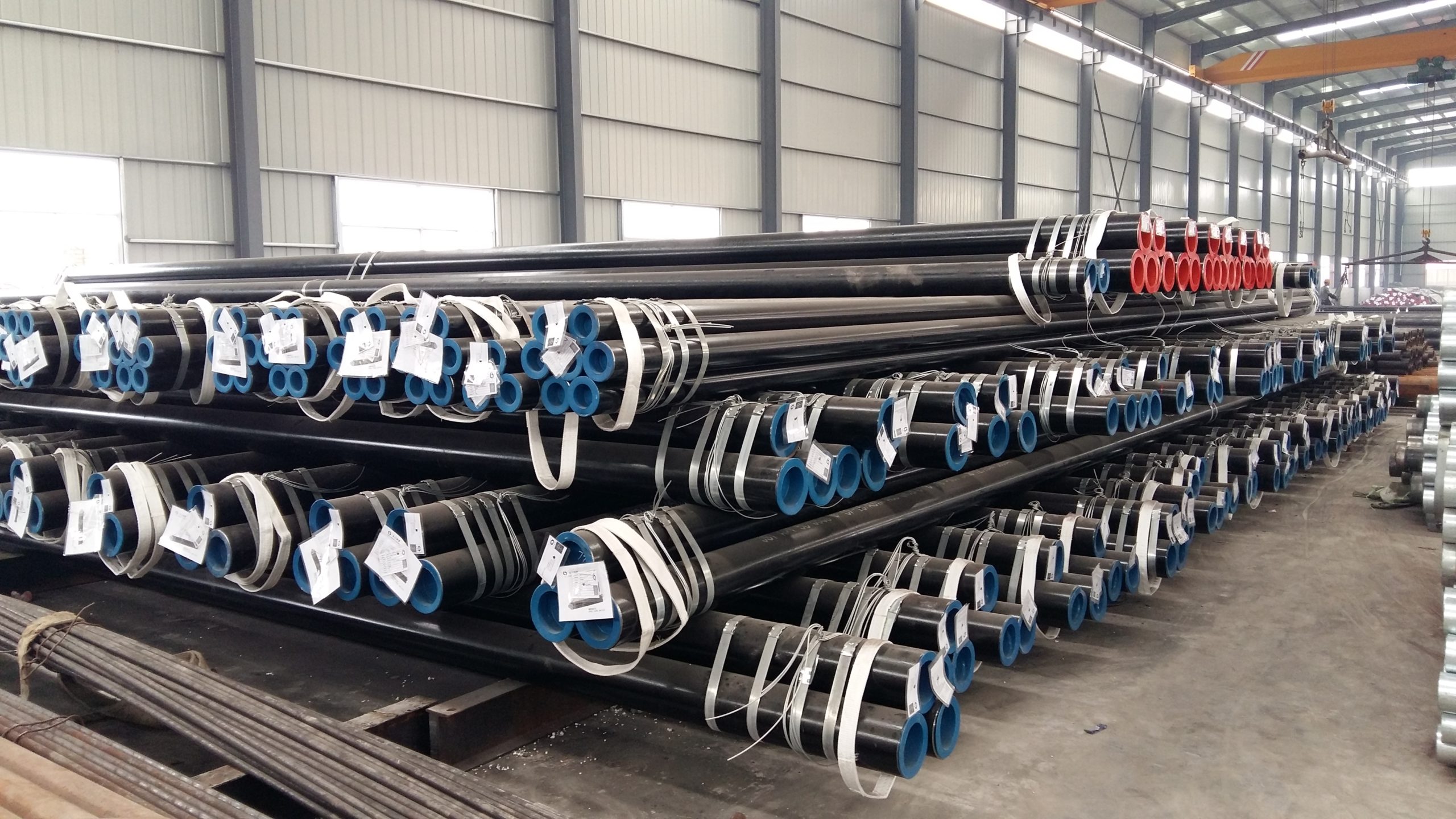

The benefits of ASTM A106 GR.B Seamless Steel Pipe are numerous. First, it is highly durable and resistant to corrosion, making it an ideal choice for a variety of applications. Additionally, it is easy to install and maintain, making it a cost-effective solution for many projects. Furthermore, it is lightweight and flexible, allowing for easy transportation and installation.

The seamless steel pipe also offers superior strength and durability. It is able to withstand high temperatures and pressures, making it suitable for a variety of applications. Additionally, it is resistant to cracking and other forms of damage, making it a reliable choice for many projects.

Finally, ASTM A106 GR.B Seamless Steel Pipe is an environmentally friendly choice. It is made from recycled materials, making it a sustainable option for many projects. Additionally, it is recyclable, making it an ideal choice for those looking to reduce their environmental impact.

Overall, ASTM A106 GR.B Seamless Steel Pipe is an excellent choice for a variety of applications. It is highly durable, easy to install and maintain, and environmentally friendly. Additionally, it is lightweight and flexible, making it an ideal choice for many projects.

Understanding the Manufacturing Process of ASTM A106 GR.B Seamless Steel Pipe

The manufacturing process of ASTM A106 GR.B Seamless Steel Pipe begins with the selection of raw materials. The raw materials used in the production of seamless steel pipes are typically round billets or hot-rolled coils. The billets are then heated in a furnace and pierced through the center to create a hollow tube.

The next step in the manufacturing process is the cold drawing process. This process involves drawing the heated hollow tube through a die to reduce its diameter and Wall thickness. The cold drawing process is done in multiple stages, with each stage reducing the diameter and wall thickness of the tube.

The next step in the manufacturing process is the heat treatment process. This process involves heating the drawn tube to a temperature of around 1100°C and then cooling it rapidly. This process helps to improve the Mechanical properties of the steel pipe.

| OD In (mm) | + | – | WT In (mm) | + | – |

| <1(25.4) | 0.10 | 0.10 | ≤1.1/2(38.1) | 20% | 0 |

| 1∼1.1/2(25.4∼38.1) | 0.15 | 0.15 | >1.1/2(38.1) | 22% | 0 |

| >1.1/2∼<2(38.1∼50.8) | 0.20 | 0.20 | |||

| 2∼<2.1/2(50.8∼63.5) | 0.25 | 0.25 | |||

| 2.1/2∼<3(63.5∼76.2) | 0.30 | 0.30 | |||

| 3∼4(76.2∼101.6) | 0.38 | 0.38 | |||

| >4∼7.1/2(101.6∼190.5) | 0.38 | 0.64 | |||

| >7.1/2∼9(190.5∼228.6) | 0.38 | 1.14 |

The final step in the manufacturing process is the finishing process. This process involves cleaning the pipe, removing any burrs or sharp edges, and then applying a protective coating. The coating helps to protect the pipe from corrosion and other environmental factors.

The manufacturing process of ASTM A106 GR.B Seamless Steel Pipe is a complex process that requires precision and expertise. The process involves several steps that must be done correctly in order to produce a high-quality product. The end result is a seamless steel pipe that is strong, durable, and able to withstand high temperatures and pressures.