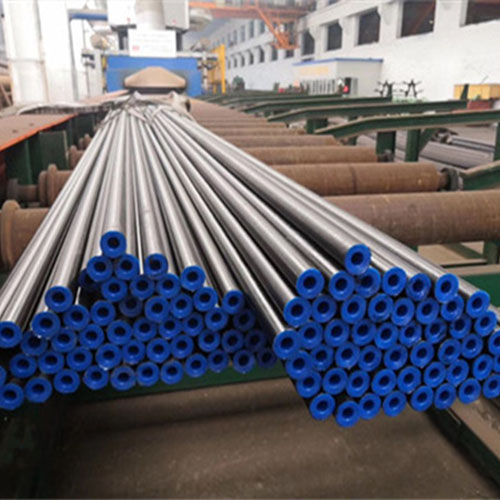

Advantages of Using ASTM A249 En 10217-7 SUS 304 316 Austenitic Welded Tube Stainless steel Seamless Pipe

Stainless steel is a popular Material in various industries due to its durability, Corrosion resistance, and aesthetic appeal. When it comes to stainless steel tubes and pipes, ASTM A249 En 10217-7 SUS 304 316 Austenitic Welded Tube Stainless Steel Seamless Pipe is a top choice for many manufacturers. This article will discuss the advantages of using this specific type of stainless steel seamless pipe. casing pipe,casing well pipe, casing supreme pipe, casing vs carrier pipe, casing for ac pipe, casing steel pipe, casing pipe size, casing pvc pipe price, casing pipe, casing pipe suppliers in China, casing capping pipe, casing drill pipe,carrier pipe,casing pipe size,bushing Flange,bushing sleeve,bushing,bushing arm,bushing bearing,bushing Reducer,bushing tool,bushing pvc,bushing meaningOne of the main advantages of ASTM A249 En 10217-7 SUS 304 316 Austenitic Welded Tube Stainless Steel Seamless Pipe is its high corrosion resistance. Stainless steel is known for its ability to resist corrosion from various elements such as water, chemicals, and salt. This makes it an ideal choice for applications where the pipe will be exposed to harsh environments or corrosive substances. The austenitic structure of SUS 304 and 316 stainless steel further enhances its corrosion resistance, making it suitable for a wide range of applications. In addition to its corrosion resistance, ASTM A249 En 10217-7 SUS 304 316 Austenitic Welded Tube Stainless Steel Seamless Pipe is also known for its high strength and durability. Stainless steel is a strong material that can withstand high pressure and temperature, making it suitable for applications where the pipe will be subjected to extreme conditions. The seamless construction of the pipe further enhances its strength and durability, ensuring that it can withstand heavy loads and harsh operating conditions.| Chemical Composition | C | Mn | P≤ | S≤ | Si≤ |

| 0.06-0.18 | 0.27-0.63 | 0.035 | 0.035 | 0.25 |

Comparison of ASTM A249 En 10217-7 SUS 304 and 316 Austenitic Welded Tube Stainless Steel Seamless Pipe

Stainless steel is a popular material in various industries due to its durability, corrosion resistance, and aesthetic appeal. When it comes to stainless steel tubes and pipes, two common grades that are often compared are ASTM A249 En 10217-7 SUS 304 and 316 austenitic welded tube stainless steel seamless pipe. These two grades have their own unique properties and applications, making them suitable for different purposes. ASTM A249 En 10217-7 SUS 304 is a versatile grade of stainless steel that is widely used in various industries such as food processing, chemical processing, and pharmaceuticals. It is known for its excellent corrosion resistance, good formability, and high strength. SUS 304 is an austenitic stainless steel, which means it has a high chromium and nickel content, making it highly resistant to corrosion and oxidation.

When comparing the two grades, SUS 316 is generally considered to be superior in terms of corrosion resistance compared to SUS 304. This is due to the presence of molybdenum in SUS 316, which enhances its resistance to pitting and crevice corrosion. As a result, SUS 316 is often preferred in applications where exposure to corrosive environments is a concern.

However, SUS 316 is also more expensive than SUS 304, which can be a factor to consider when choosing between the two grades. In applications where corrosion resistance is not a primary concern, SUS 304 may be a more cost-effective option while still providing good overall performance.

In terms of Mechanical properties, both SUS 304 and 316 have similar Tensile strength and Yield strength. However, SUS 316 has slightly higher tensile strength and yield strength compared to SUS 304, making it slightly stronger in certain applications.

When comparing the two grades, SUS 316 is generally considered to be superior in terms of corrosion resistance compared to SUS 304. This is due to the presence of molybdenum in SUS 316, which enhances its resistance to pitting and crevice corrosion. As a result, SUS 316 is often preferred in applications where exposure to corrosive environments is a concern.

However, SUS 316 is also more expensive than SUS 304, which can be a factor to consider when choosing between the two grades. In applications where corrosion resistance is not a primary concern, SUS 304 may be a more cost-effective option while still providing good overall performance.

In terms of Mechanical properties, both SUS 304 and 316 have similar Tensile strength and Yield strength. However, SUS 316 has slightly higher tensile strength and yield strength compared to SUS 304, making it slightly stronger in certain applications.

| Labels | Outside diameter (d/mm) | T&C (kg/m) | Wall thickness (t/mm) | Type of end-finish | |||||||

| 1 | 2 | J55/ K55 | M65 | L80/ R95 | N80-1/Q | C90/ T95 | P110 | Q125 | |||

| 4-1/2 | 9.50 | 114.30 | 14.14 | 5.21 | PS | PS | – | – | – | – | – |

| 10.50 | 114.30 | 15.63 | 5.69 | PSB | PSB | – | – | – | – | – | |

| 11.60 | 114.30 | 17.26 | 6.35 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 13.50 | 114.30 | 20.09 | 7.37 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 15.10 | 114.30 | 22.47 | 8.56 | – | – | – | – | – | PLB | PLB | |

| 5 | 11.50 | 127.00 | 17.11 | 5.59 | PS | PS | – | – | – | – | – |

| 13.00 | 127.00 | 19.35 | 6.43 | PSLB | PSLB | – | – | – | – | – | |

| 15.00 | 127.00 | 22.32 | 7.52 | PSLB | PLB | SLB | PLB | PLB | PLB | ||

| 18.00 | 127.00 | 26.79 | 9.19 | – | PLB | SLB | PLB | PLB | PLB | PLB | |

| 21.40 | 127.00 | 31.85 | 11.10 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 23.20 | 127.00 | 34.53 | 12.14 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 24.10 | 127.00 | 35.87 | 12.70 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 5-1/2 | 14.00 | 139.70 | 20.83 | 6.20 | PS | PS | – | – | – | – | – |

| 15.50 | 139.70 | 23.07 | 6.98 | PSLB | PSLB | – | – | – | – | – | |

| 17.00 | 139.70 | 25.30 | 7.72 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 20.00 | 139.70 | 29.76 | 9.17 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 23.00 | 139.70 | 34.23 | 10.54 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 26.80 | 139.70 | 39.88 | 12.70 | – | – | – | – | P | – | – | |

| 29.70 | 139.70 | 44.20 | 14.27 | – | – | – | – | P | – | – | |

| 32.60 | 139.70 | 48.52 | 15.88 | – | – | – | – | P | – | – | |

| 35.30 | 139.70 | 52.53 | 17.45 | – | – | – | – | P | – | – | |

| 38.00 | 139.70 | 56.55 | 19.05 | – | – | – | – | P | – | – | |

| 40.50 | 139.70 | 60.27 | 20.62 | – | – | – | – | P | – | – | |

| 43.10 | 139.70 | 64.14 | 22.22 | – | – | – | – | P | – | – | |

| 6-5/8 | 20.00 | 168.28 | 29.76 | 7.32 | PSLB | PSLB | – | – | – | – | – |

| 24.00 | 168.28 | 35.72 | 8.94 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 28.00 | 168.28 | 41.67 | 10.59 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 32.00 | 168.28 | 47.62 | 12.06 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 7 | 17.00 | 177.80 | 25.30 | 5.87 | – | – | – | – | – | – | – |

| 20.00 | 177.80 | 29.76 | 6.91 | PS | PS | – | – | – | – | – | |

| 23.00 | 177.80 | 34.23 | 8.05 | PSLB | PLB | PLB | PLB | PLB | – | – | |

| 26.00 | 177.80 | 38.69 | 9.19 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 29.00 | 177.80 | 43.16 | 10.36 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 32.00 | 177.80 | 47.62 | 11.51 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 35.00 | 177.80 | 52.09 | 12.65 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 38.00 | 177.80 | 56.55 | 13.72 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 42.70 | 177.80 | 63.55 | 15.88 | – | – | – | – | P | – | – | |

| 46.40 | 177.80 | 69.05 | 17.45 | – | – | – | – | P | – | – | |

| 50.10 | 177.80 | 74.56 | 19.05 | – | – | – | – | P | – | – | |

| 53.60 | 177.80 | 79.77 | 20.62 | – | – | – | – | P | – | – | |

| 57.10 | 177.80 | 84.98 | 22.22 | – | – | – | – | P | – | – | |

| 7-5/8 | 24.00 | 193.68 | 35.72 | 7.62 | – | – | – | – | – | – | |

| 26.40 | 193.68 | 39.29 | 8.33 | PSLB | PSLB | PLB | PLB | PLB | – | – | |

| 29.70 | 193.68 | 44.20 | 9.52 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 33.70 | 193.68 | 50.15 | 10.92 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 39.00 | 193.68 | 58.04 | 12.70 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 42.80 | 193.68 | 63.69 | 14.27 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 45.30 | 193.68 | 67.42 | 15.11 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 47.10 | 193.68 | 70.09 | 15.88 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 51.20 | 193.68 | 76.20 | 17.45 | – | – | – | – | P | – | – | |

| 55.30 | 193.68 | 82.30 | 19.05 | – | – | – | – | P | – | – | |

| 7-3/4 | 46.10 | 196.85 | 68.61 | 15.11 | – | – | P | P | P | P | P |

| 8-5/8 | 24.00 | 219.08 | 35.72 | 6.71 | PS | PS | – | – | – | – | – |

| 28.00 | 219.08 | 41.67 | 7.72 | PS | – | – | – | – | – | ||

| 32.00 | 219.08 | 47.62 | 8.94 | PSLB | PSLB | – | – | – | – | – | |

| 36.00 | 219.08 | 53.58 | 10.16 | PSLB | PSLB | PLB | PLB | PLB | PLB | – | |

| 40.00 | 219.08 | 59.53 | 11.43 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 44.00 | 219.08 | 65.48 | 12.70 | – | – | PLB | PLB | PLB | PLB | – | |

| 49.00 | 219.08 | 72.92 | 14.15 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 9-5/8 | 32.30 | 244.48 | 48.07 | 7.92 | – | – | – | – | – | – | – |

| 36.00 | 244.48 | 53.58 | 8.94 | PSLB | PSLB | – | – | – | – | – | |

| 40.00 | 244.48 | 59.53 | 10.03 | PSLB | PSLB | PLB | PLB | PLB | – | – | |

| 43.50 | 244.48 | 64.74 | 11.05 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 47.00 | 244.48 | 69.95 | 11.99 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 53.50 | 244.48 | 79.62 | 13.84 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 58.40 | 244.48 | 86.91 | 15.11 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 59.40 | 244.48 | 88.40 | 15.47 | – | – | – | – | P | – | – | |

| 64.90 | 244.48 | 96.58 | 17.07 | – | – | – | – | P | – | – | |

| 70.30 | 244.48 | 104.62 | 18.64 | – | – | – | – | P | – | – | |

| 75.60 | 244.48 | 112.51 | 20.24 | – | – | – | – | P | – | – | |

| 10-3/4 | 32.75 | 273.05 | 48.74 | 7.09 | – | – | – | – | – | – | – |

| 40.50 | 273.05 | 60.27 | 8.89 | PSB | PSB | – | – | – | – | – | |

| 45.50 | 273.05 | 67.71 | 10.16 | PSB | PSB | – | – | – | – | – | |

| 51.00 | 273.05 | 75.90 | 11.43 | PSB | PSB | PSB | PSB | PSB | PSB | – | |

| 55.50 | 273.05 | 82.60 | 12.57 | – | PSB | PSB | PSB | PSB | PSB | – | |

| 60.70 | 273.05 | 90.33 | 13.84 | – | – | – | – | PSB | PSB | PSB | |

| 65.70 | 273.05 | 97.77 | 15.11 | – | – | – | – | PSB | PSB | PSB | |

| 73.20 | 273.05 | 108.94 | 17.07 | – | – | – | – | P | – | – | |

| 79.20 | 273.05 | 117.87 | 18.64 | – | – | – | – | P | – | – | |

| 85.30 | 273.05 | 126.94 | 20.24 | – | – | – | – | P | – | – | |

| 11-3/4 | 42.00 | 298.45 | 62.50 | 8.46 | – | – | – | – | – | – | – |

| 47.00 | 298.45 | 69.95 | 9.53 | PSB | PSB | – | – | – | – | – | |

| 54.00 | 298.45 | 80.36 | 11.05 | PSB | PSB | – | – | – | – | – | |

| 60.00 | 298.45 | 89.29 | 12.42 | PSB | PSB | PSB | PSB | PSB | PSB | PSB | |

| 65.00 | 298.45 | 96.73 | 13.56 | – | – | P | P | P | P | P | |

| 71.00 | 298.45 | 105.66 | 14.78 | – | – | P | P | P | P | P | |

| 13-3/8 | 48.00 | 339.72 | 71.43 | 8.38 | – | – | – | – | – | – | – |

| 54.50 | 339.72 | 81.11 | 9.65 | PSB | PSB | – | – | – | – | – | |

| 61.00 | 339.72 | 90.78 | 10.92 | PSB | PSB | – | – | – | – | – | |

| 68.00 | 339.72 | 101.20 | 12.19 | PSB | PSB | PSB | PSB | PSB | PSB | – | |

| 72.00 | 339.72 | 107.15 | 13.06 | – | – | PSB | PSB | PSB | PSB | PSB | |

| 16 | 65.00 | 406.40 | 96.73 | 9.53 | – | – | – | – | – | – | – |

| 75.00 | 406.40 | 111.62 | 11.13 | PSB | PSB | – | – | – | – | – | |

| 84.00 | 406.40 | 125.01 | 12.57 | PSB | PSB | – | – | – | – | – | |

| 109.00 | 406.40 | 162.21 | 16.66 | P | – | P | P | – | P | P | |

| 18-5/8 | 87.50 | 473.08 | 130.22 | 11.05 | PSB | PSB | – | – | – | – | – |

| 20 | 94.00 | 508.00 | 139.89 | 11.13 | PSLB | PSLB | – | – | – | – | – |

| 106.50 | 508.00 | 158.49 | 12.70 | PSLB | PSLB | – | – | – | – | – | |

| 133.00 | 508.00 | 197.93 | 16.13 | PSLB | – | – | – | – | – | – | |