Advantages of Using En ASTM API S355 A53b A106 Gr. B A336 Carbon Structure Seamless steel Pipe

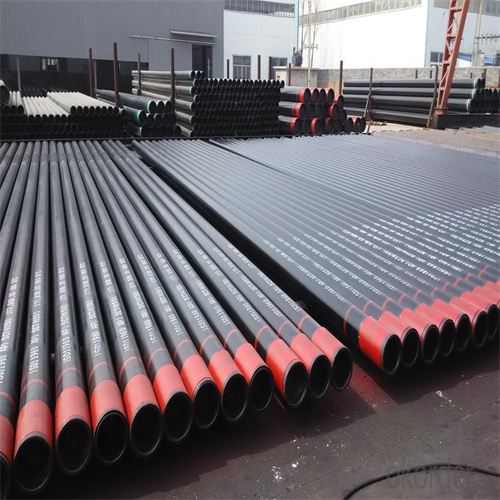

En ASTM API S355 A53b A106 Gr. B A336 Carbon Structure Seamless Steel Pipe is a popular choice for many industries due to its numerous advantages. One of the main benefits of using this type of steel pipe is its high strength and durability. The seamless construction of the pipe ensures that it can withstand high pressure and temperature, making it ideal for use in a variety of applications. Another advantage of En ASTM API S355 A53b A106 Gr. B A336 Carbon Structure Seamless Steel Pipe is its versatility. This type of pipe can be used in a wide range of industries, including construction, Oil and gas, and automotive. Its ability to be easily welded and machined makes it a popular choice for many different projects.

Another advantage of En ASTM API S355 A53b A106 Gr. B A336 Carbon Structure Seamless Steel Pipe is its versatility. This type of pipe can be used in a wide range of industries, including construction, Oil and gas, and automotive. Its ability to be easily welded and machined makes it a popular choice for many different projects.

In addition to its strength and versatility, En ASTM API S355 A53b A106 Gr. B A336 Carbon Structure Seamless Steel Pipe is also known for its Corrosion resistance. This makes it an ideal choice for applications where the pipe will be exposed to harsh environments or corrosive materials. The seamless construction of the pipe helps to prevent corrosion and rust, ensuring a longer lifespan for the pipe.

Furthermore, En ASTM API S355 A53b A106 Gr. B A336 Carbon Structure Seamless Steel Pipe is known for its cost-effectiveness. The seamless construction of the pipe reduces the need for additional fittings and connectors, saving both time and money during installation. Additionally, the durability of the pipe means that it will require less maintenance over time, further reducing costs for the user.

casing pipe,casing well pipe, casing supreme pipe, casing vs carrier pipe, casing for ac pipe, casing steel pipe, casing pipe size, casing pvc pipe price, casing pipe, casing pipe suppliers in China, casing capping pipe, casing drill pipe,carrier pipe,casing pipe size,bushing Flange,bushing sleeve,bushing,bushing arm,bushing bearing,bushing Reducer,bushing tool,bushing pvc,bushing meaning

En ASTM API S355 A53b A106 Gr. B A336 Carbon Structure Seamless Steel Pipe is also known for its high performance. The seamless construction of the pipe allows for smooth fluid flow, reducing pressure drop and improving overall efficiency. This makes it an ideal choice for applications where high performance is essential, such as in fluid pressure and boiler systems.

Overall, En ASTM API S355 A53b A106 Gr. B A336 Carbon Structure Seamless Steel Pipe offers numerous advantages for a wide range of industries. Its high strength, versatility, corrosion resistance, cost-effectiveness, and high performance make it a popular choice for many different applications. Whether you are working in construction, oil and gas, automotive, or any other industry, En ASTM API S355 A53b A106 Gr. B A336 Carbon Structure Seamless Steel Pipe is a reliable and durable option that will meet your needs.

In addition to its strength and versatility, En ASTM API S355 A53b A106 Gr. B A336 Carbon Structure Seamless Steel Pipe is also known for its Corrosion resistance. This makes it an ideal choice for applications where the pipe will be exposed to harsh environments or corrosive materials. The seamless construction of the pipe helps to prevent corrosion and rust, ensuring a longer lifespan for the pipe.

Furthermore, En ASTM API S355 A53b A106 Gr. B A336 Carbon Structure Seamless Steel Pipe is known for its cost-effectiveness. The seamless construction of the pipe reduces the need for additional fittings and connectors, saving both time and money during installation. Additionally, the durability of the pipe means that it will require less maintenance over time, further reducing costs for the user.

casing pipe,casing well pipe, casing supreme pipe, casing vs carrier pipe, casing for ac pipe, casing steel pipe, casing pipe size, casing pvc pipe price, casing pipe, casing pipe suppliers in China, casing capping pipe, casing drill pipe,carrier pipe,casing pipe size,bushing Flange,bushing sleeve,bushing,bushing arm,bushing bearing,bushing Reducer,bushing tool,bushing pvc,bushing meaning

En ASTM API S355 A53b A106 Gr. B A336 Carbon Structure Seamless Steel Pipe is also known for its high performance. The seamless construction of the pipe allows for smooth fluid flow, reducing pressure drop and improving overall efficiency. This makes it an ideal choice for applications where high performance is essential, such as in fluid pressure and boiler systems.

Overall, En ASTM API S355 A53b A106 Gr. B A336 Carbon Structure Seamless Steel Pipe offers numerous advantages for a wide range of industries. Its high strength, versatility, corrosion resistance, cost-effectiveness, and high performance make it a popular choice for many different applications. Whether you are working in construction, oil and gas, automotive, or any other industry, En ASTM API S355 A53b A106 Gr. B A336 Carbon Structure Seamless Steel Pipe is a reliable and durable option that will meet your needs.Importance of Large Diameter Thick Wall Sch20 Alloy Seamless Fluid Pressure Boiler Tube API Pipe

In the world of industrial applications, the importance of large diameter thick wall Sch20 alloy seamless fluid pressure boiler tube API pipe cannot be overstated. These pipes play a crucial role in various industries, including oil and gas, petrochemical, power generation, and more. They are designed to withstand high pressure and temperature conditions, making them essential for transporting fluids and gases in a safe and efficient manner. One of the key advantages of large diameter thick wall Sch20 alloy seamless fluid pressure boiler tube API pipe is their durability. These pipes are made from high-quality materials such as ASTM API S355, A53b, A106 Gr. B, and A336 carbon structure seamless steel, which are known for their strength and resistance to corrosion. This ensures that the pipes can withstand the harsh conditions they are exposed to, including high pressure, temperature fluctuations, and corrosive substances.| OD In (mm) | + | – | WT In (mm) | + | – |

| <1(25.4) | 0.10 | 0.10 | ≤1.1/2(38.1) | 20% | 0 |

| 1∼1.1/2(25.4∼38.1) | 0.15 | 0.15 | >1.1/2(38.1) | 22% | 0 |

| >1.1/2∼<2(38.1∼50.8) | 0.20 | 0.20 | |||

| 2∼<2.1/2(50.8∼63.5) | 0.25 | 0.25 | |||

| 2.1/2∼<3(63.5∼76.2) | 0.30 | 0.30 | |||

| 3∼4(76.2∼101.6) | 0.38 | 0.38 | |||

| >4∼7.1/2(101.6∼190.5) | 0.38 | 0.64 | |||

| >7.1/2∼9(190.5∼228.6) | 0.38 | 1.14 |

| Labels | Outside diameter (d/mm) | T&C (kg/m) | Wall thickness (t/mm) | Type of end-finish | |||||||

| 1 | 2 | J55/ K55 | M65 | L80/ R95 | N80-1/Q | C90/ T95 | P110 | Q125 | |||

| 4-1/2 | 9.50 | 114.30 | 14.14 | 5.21 | PS | PS | – | – | – | – | – |

| 10.50 | 114.30 | 15.63 | 5.69 | PSB | PSB | – | – | – | – | – | |

| 11.60 | 114.30 | 17.26 | 6.35 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 13.50 | 114.30 | 20.09 | 7.37 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 15.10 | 114.30 | 22.47 | 8.56 | – | – | – | – | – | PLB | PLB | |

| 5 | 11.50 | 127.00 | 17.11 | 5.59 | PS | PS | – | – | – | – | – |

| 13.00 | 127.00 | 19.35 | 6.43 | PSLB | PSLB | – | – | – | – | – | |

| 15.00 | 127.00 | 22.32 | 7.52 | PSLB | PLB | SLB | PLB | PLB | PLB | ||

| 18.00 | 127.00 | 26.79 | 9.19 | – | PLB | SLB | PLB | PLB | PLB | PLB | |

| 21.40 | 127.00 | 31.85 | 11.10 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 23.20 | 127.00 | 34.53 | 12.14 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 24.10 | 127.00 | 35.87 | 12.70 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 5-1/2 | 14.00 | 139.70 | 20.83 | 6.20 | PS | PS | – | – | – | – | – |

| 15.50 | 139.70 | 23.07 | 6.98 | PSLB | PSLB | – | – | – | – | – | |

| 17.00 | 139.70 | 25.30 | 7.72 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 20.00 | 139.70 | 29.76 | 9.17 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 23.00 | 139.70 | 34.23 | 10.54 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 26.80 | 139.70 | 39.88 | 12.70 | – | – | – | – | P | – | – | |

| 29.70 | 139.70 | 44.20 | 14.27 | – | – | – | – | P | – | – | |

| 32.60 | 139.70 | 48.52 | 15.88 | – | – | – | – | P | – | – | |

| 35.30 | 139.70 | 52.53 | 17.45 | – | – | – | – | P | – | – | |

| 38.00 | 139.70 | 56.55 | 19.05 | – | – | – | – | P | – | – | |

| 40.50 | 139.70 | 60.27 | 20.62 | – | – | – | – | P | – | – | |

| 43.10 | 139.70 | 64.14 | 22.22 | – | – | – | – | P | – | – | |

| 6-5/8 | 20.00 | 168.28 | 29.76 | 7.32 | PSLB | PSLB | – | – | – | – | – |

| 24.00 | 168.28 | 35.72 | 8.94 | PSLB | PLB | PLB | PLB | PLB | PLB | – | |

| 28.00 | 168.28 | 41.67 | 10.59 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 32.00 | 168.28 | 47.62 | 12.06 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 7 | 17.00 | 177.80 | 25.30 | 5.87 | – | – | – | – | – | – | – |

| 20.00 | 177.80 | 29.76 | 6.91 | PS | PS | – | – | – | – | – | |

| 23.00 | 177.80 | 34.23 | 8.05 | PSLB | PLB | PLB | PLB | PLB | – | – | |

| 26.00 | 177.80 | 38.69 | 9.19 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 29.00 | 177.80 | 43.16 | 10.36 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 32.00 | 177.80 | 47.62 | 11.51 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 35.00 | 177.80 | 52.09 | 12.65 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 38.00 | 177.80 | 56.55 | 13.72 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 42.70 | 177.80 | 63.55 | 15.88 | – | – | – | – | P | – | – | |

| 46.40 | 177.80 | 69.05 | 17.45 | – | – | – | – | P | – | – | |

| 50.10 | 177.80 | 74.56 | 19.05 | – | – | – | – | P | – | – | |

| 53.60 | 177.80 | 79.77 | 20.62 | – | – | – | – | P | – | – | |

| 57.10 | 177.80 | 84.98 | 22.22 | – | – | – | – | P | – | – | |

| 7-5/8 | 24.00 | 193.68 | 35.72 | 7.62 | – | – | – | – | – | – | |

| 26.40 | 193.68 | 39.29 | 8.33 | PSLB | PSLB | PLB | PLB | PLB | – | – | |

| 29.70 | 193.68 | 44.20 | 9.52 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 33.70 | 193.68 | 50.15 | 10.92 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 39.00 | 193.68 | 58.04 | 12.70 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 42.80 | 193.68 | 63.69 | 14.27 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 45.30 | 193.68 | 67.42 | 15.11 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 47.10 | 193.68 | 70.09 | 15.88 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 51.20 | 193.68 | 76.20 | 17.45 | – | – | – | – | P | – | – | |

| 55.30 | 193.68 | 82.30 | 19.05 | – | – | – | – | P | – | – | |

| 7-3/4 | 46.10 | 196.85 | 68.61 | 15.11 | – | – | P | P | P | P | P |

| 8-5/8 | 24.00 | 219.08 | 35.72 | 6.71 | PS | PS | – | – | – | – | – |

| 28.00 | 219.08 | 41.67 | 7.72 | PS | – | – | – | – | – | ||

| 32.00 | 219.08 | 47.62 | 8.94 | PSLB | PSLB | – | – | – | – | – | |

| 36.00 | 219.08 | 53.58 | 10.16 | PSLB | PSLB | PLB | PLB | PLB | PLB | – | |

| 40.00 | 219.08 | 59.53 | 11.43 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 44.00 | 219.08 | 65.48 | 12.70 | – | – | PLB | PLB | PLB | PLB | – | |

| 49.00 | 219.08 | 72.92 | 14.15 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 9-5/8 | 32.30 | 244.48 | 48.07 | 7.92 | – | – | – | – | – | – | – |

| 36.00 | 244.48 | 53.58 | 8.94 | PSLB | PSLB | – | – | – | – | – | |

| 40.00 | 244.48 | 59.53 | 10.03 | PSLB | PSLB | PLB | PLB | PLB | – | – | |

| 43.50 | 244.48 | 64.74 | 11.05 | – | PLB | PLB | PLB | PLB | PLB | – | |

| 47.00 | 244.48 | 69.95 | 11.99 | – | PLB | PLB | PLB | PLB | PLB | PLB | |

| 53.50 | 244.48 | 79.62 | 13.84 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 58.40 | 244.48 | 86.91 | 15.11 | – | – | PLB | PLB | PLB | PLB | PLB | |

| 59.40 | 244.48 | 88.40 | 15.47 | – | – | – | – | P | – | – | |

| 64.90 | 244.48 | 96.58 | 17.07 | – | – | – | – | P | – | – | |

| 70.30 | 244.48 | 104.62 | 18.64 | – | – | – | – | P | – | – | |

| 75.60 | 244.48 | 112.51 | 20.24 | – | – | – | – | P | – | – | |

| 10-3/4 | 32.75 | 273.05 | 48.74 | 7.09 | – | – | – | – | – | – | – |

| 40.50 | 273.05 | 60.27 | 8.89 | PSB | PSB | – | – | – | – | – | |

| 45.50 | 273.05 | 67.71 | 10.16 | PSB | PSB | – | – | – | – | – | |

| 51.00 | 273.05 | 75.90 | 11.43 | PSB | PSB | PSB | PSB | PSB | PSB | – | |

| 55.50 | 273.05 | 82.60 | 12.57 | – | PSB | PSB | PSB | PSB | PSB | – | |

| 60.70 | 273.05 | 90.33 | 13.84 | – | – | – | – | PSB | PSB | PSB | |

| 65.70 | 273.05 | 97.77 | 15.11 | – | – | – | – | PSB | PSB | PSB | |

| 73.20 | 273.05 | 108.94 | 17.07 | – | – | – | – | P | – | – | |

| 79.20 | 273.05 | 117.87 | 18.64 | – | – | – | – | P | – | – | |

| 85.30 | 273.05 | 126.94 | 20.24 | – | – | – | – | P | – | – | |

| 11-3/4 | 42.00 | 298.45 | 62.50 | 8.46 | – | – | – | – | – | – | – |

| 47.00 | 298.45 | 69.95 | 9.53 | PSB | PSB | – | – | – | – | – | |

| 54.00 | 298.45 | 80.36 | 11.05 | PSB | PSB | – | – | – | – | – | |

| 60.00 | 298.45 | 89.29 | 12.42 | PSB | PSB | PSB | PSB | PSB | PSB | PSB | |

| 65.00 | 298.45 | 96.73 | 13.56 | – | – | P | P | P | P | P | |

| 71.00 | 298.45 | 105.66 | 14.78 | – | – | P | P | P | P | P | |

| 13-3/8 | 48.00 | 339.72 | 71.43 | 8.38 | – | – | – | – | – | – | – |

| 54.50 | 339.72 | 81.11 | 9.65 | PSB | PSB | – | – | – | – | – | |

| 61.00 | 339.72 | 90.78 | 10.92 | PSB | PSB | – | – | – | – | – | |

| 68.00 | 339.72 | 101.20 | 12.19 | PSB | PSB | PSB | PSB | PSB | PSB | – | |

| 72.00 | 339.72 | 107.15 | 13.06 | – | – | PSB | PSB | PSB | PSB | PSB | |

| 16 | 65.00 | 406.40 | 96.73 | 9.53 | – | – | – | – | – | – | – |

| 75.00 | 406.40 | 111.62 | 11.13 | PSB | PSB | – | – | – | – | – | |

| 84.00 | 406.40 | 125.01 | 12.57 | PSB | PSB | – | – | – | – | – | |

| 109.00 | 406.40 | 162.21 | 16.66 | P | – | P | P | – | P | P | |

| 18-5/8 | 87.50 | 473.08 | 130.22 | 11.05 | PSB | PSB | – | – | – | – | – |

| 20 | 94.00 | 508.00 | 139.89 | 11.13 | PSLB | PSLB | – | – | – | – | – |

| 106.50 | 508.00 | 158.49 | 12.70 | PSLB | PSLB | – | – | – | – | – | |

| 133.00 | 508.00 | 197.93 | 16.13 | PSLB | – | – | – | – | – | – | |