Max-Pleate Filter Cartridge 6 inch A Series Used in power station

PP Filter are widely used in high quality beer&beverage, Biological products, medical, Pharmaceutical and air filtration.

In different industry with different requirement, Kinda produce PP Filter of WEP/EWPB/HFP/HPP/ APP/PPT series to meet various demands.

Please contact us and tell us your appilication and main factor you thinking about, we not only the filter manufacturer, also provide prossional filtration separation solutions, filtration testing and filtration guidance for globbal customers.

We had supply filter many times to Eskom in SA for the power station!!!

Max-Pleate Filter Cartridge 6 inch A Series

With 6-inch large diameter and coreless design, Max-Pleat A expands effective filtration area signicantly.

The improved EFA(effective ltration area) will impress

you by sharply decreased change-out frequency and

obviously smaller operation footprint .

Features – High Flow Rate Max-Pleate Filter Cartridge 6 inch A Series

6″ diameter, large geometry

Larger filtration surface leads to higher flow rate,

lower delta pressure and longer service life.

Consumable cost and labor expense will be saved.

Multi-application suitability covers Cooling Water

Filtration, RO Pre-filtration, Seawater Desalination,

Amine Circulation Filtraion and kinds of chemical

solution filtration.

Features – Cost Saving Max-Pleate Filter Cartridge 6 inch A Series

High flow capacity reduces upfront capital cost

Up to 40 times fewer cartridg to change out

Up to 50% smaller filter system possible

Handle design leads to much faster, easier

Filter changeout

Features – High Dirt Holding Capacity Max-Pleate Filter Cartridge 6 inch A Series

Depth pleated structure combines multiple

filtration medias brings higher dirt holding

capacity and absolute retention efficiency.

Inside-out flow pattern design holds most debris

in and prevents housing pollution.

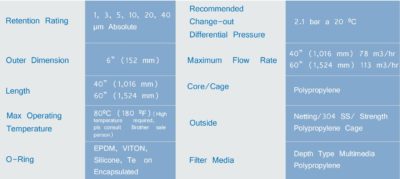

Specification

Typical Application

Power Condensate System

Municipal Water

Chemical

Petrochemicals

Electronics (RO Preltration, Process

Water)

Food& Beverage (process Water)

Pharmeceutical (process water)

Waste Water

Note:

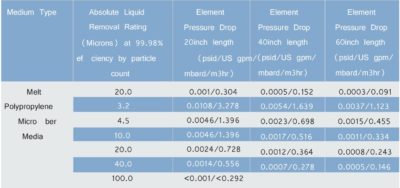

Max-Pleate Filter Cartridge 6 inch A Series

The test procedure used is an adaptation of ISO 4572, modified to determine the

micron size above which particles are quantitatively removed.

Pressure drop in PSID per US gpm for the cartridge Length shown. Multiply this value

by the total system flow to determine the aqueous pressure drop. Next for High Flow

filer only;it must be added to the pressure drop due to the Brother High Flow Filter

Housing.

Ordering Information

MAHF P 050 40 E

Cartridge Design Media

P=Polypropylene

G=GlassFiber

Removing Rating 010=1um

Length 40=40inch 60=60inch

O ring Material E=EPDM 030=3um V=Fluororubber S=Silicon 050=5um 100=10um 200=20um 400=40um 700=70um

N=Buna-N rubber

4 Brother Max-Pleat A Series

Instructions:

To install a filter element, remove the element hold down plate by lifting it off the

locating pins. Lubricate the O-ring on the open-end of the lter with a compatible fluid, and

slide the closed end of the filter into the perforated cage, which is welded to the

tubesheet. Seat the elements in place by pressing down on the open-end of the

filter until the element is snug in the tubesheet.

This provides a seal between the filter and housing via the filter O-ring.

The open-end Cap must be below the tubesheet surface.

After installing all the filter cartridges, reinstall and secure the element hold down

plate by guiding it over the locating pins on the tubesheet.

The purpose of the hold down plate is to prevent the elements from becoming

dislodged in the event of reverse flow.

A filter element tool is provided with each housing to aid with the installation and

removal of the filter cartridges.

This tool eliminates the need for an operator to reach within the filter vessel to

either remove or install the filters.

Cangzhou Zhongshun steel Pipe Trade Co.,Ltd

Add:Room 101,Custom House Building,Cangzhou City ,Hebei Province,China

Email:lisa@zssteeltube.com

Tel: 0086 18132295089