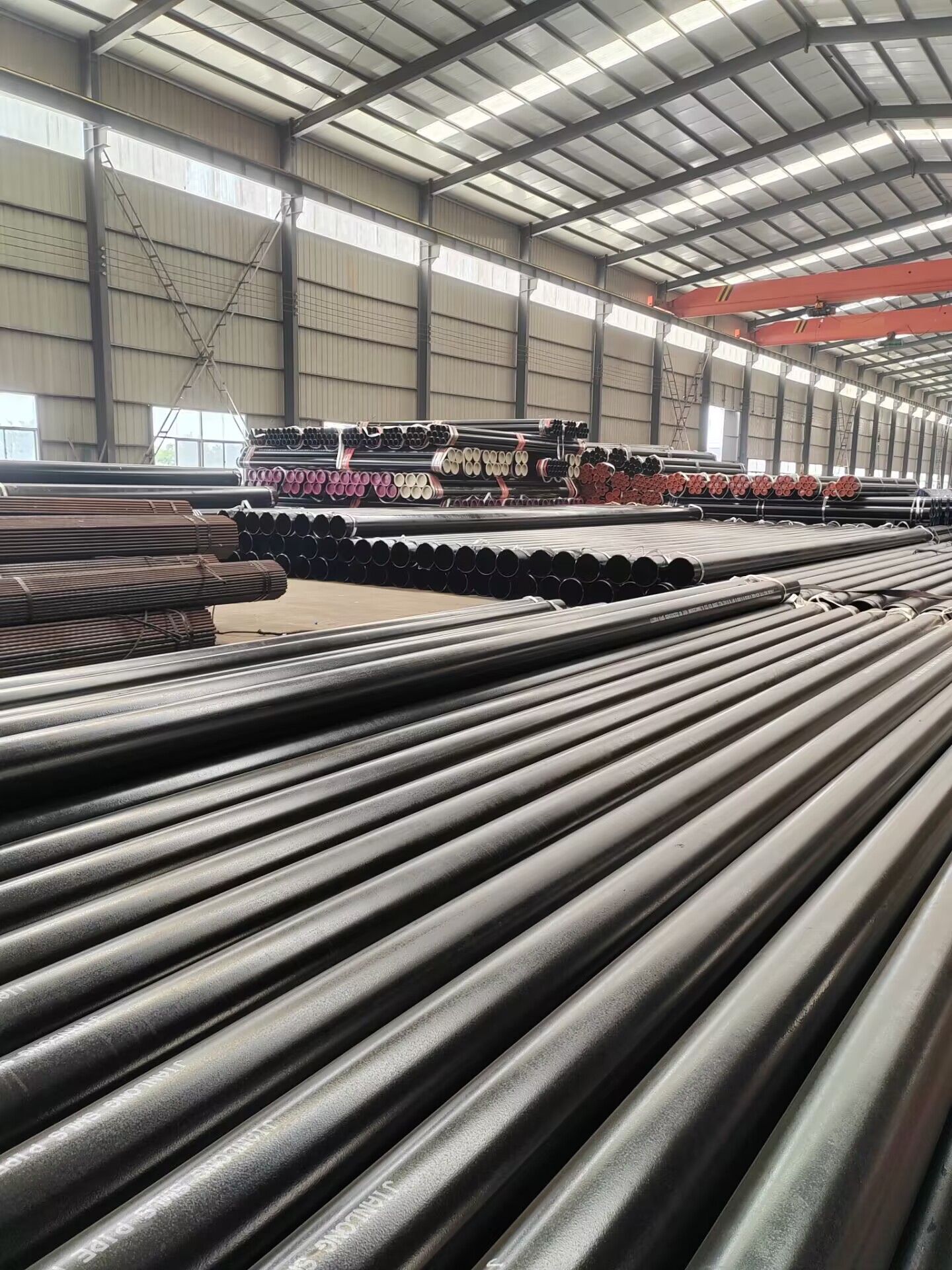

Advantages of Using Seamless steel Pipe & Tube in Industrial Applications

Seamless steel pipes and tubes are essential components in various industrial applications due to their numerous advantages. These seamless products are manufactured without any Welding seam, which makes them stronger and more reliable than welded pipes. In this article, we will explore the advantages of using seamless steel pipes and tubes in industrial settings.

2 dom Tubing

One of the primary advantages of seamless steel pipes and tubes is their superior strength. Because they are manufactured without any welding seam, seamless pipes and tubes are able to withstand high pressure and temperature conditions. This makes them ideal for use in industries such as Oil and gas, petrochemical, and power generation, where the pipes are subjected to extreme conditions.

Another advantage of seamless steel pipes and tubes is their uniformity in shape and size. Since seamless pipes are manufactured using a solid round steel billet, they have a consistent diameter throughout their Length. This uniformity makes it easier to install and connect seamless pipes and tubes in industrial systems, reducing the risk of leaks and failures.

Seamless steel pipes and tubes also have a smooth interior surface, which allows for efficient flow of fluids and gases. The absence of welding seams eliminates the risk of corrosion and erosion, ensuring a longer service life for seamless pipes and tubes. This makes them a cost-effective solution for industries that require reliable and durable piping systems.

In addition to their strength and durability, seamless steel pipes and tubes are also highly resistant to corrosion. The seamless manufacturing process eliminates the need for any welding, which is a common source of corrosion in welded pipes. This Corrosion resistance makes seamless pipes and tubes suitable for use in industries where exposure to corrosive substances is a concern.

Furthermore, seamless steel pipes and tubes are easy to maintain and repair. Because they are manufactured as a single piece, seamless pipes and tubes can be replaced or repaired without the need for extensive welding work. This reduces downtime and maintenance costs for industrial facilities, making seamless pipes and tubes a practical choice for many applications.

Seamless steel pipes and tubes are also available in a wide range of sizes and specifications to meet the specific requirements of different industrial applications. Whether you need a small diameter pipe for a residential plumbing system or a large diameter tube for a high-pressure industrial process, seamless steel products can be customized to fit your needs.

In conclusion, seamless steel pipes and tubes offer numerous advantages for industrial applications. Their superior strength, uniformity, corrosion resistance, and ease of maintenance make them a reliable and cost-effective choice for a wide range of industries. If you are looking for durable and efficient piping solutions for your industrial systems, seamless steel pipes and tubes are definitely worth considering.

How to Choose the Right Seamless Steel Pipe & Tube for Your Project

When it comes to choosing the right seamless steel pipe and tube for your project, there are several factors to consider. Seamless steel pipes and tubes are widely used in various industries such as oil and gas, construction, automotive, and manufacturing due to their durability, strength, and resistance to corrosion. However, with so many options available in the market, it can be overwhelming to select the best one for your specific needs.

One of the first things to consider when choosing a seamless steel pipe and tube is the Material. Seamless steel pipes and tubes are typically made from Carbon steel, Stainless steel, or Alloy steel. Each material has its own unique properties and advantages, so it’s important to choose the one that best suits your project requirements. Carbon steel pipes are known for their strength and durability, making them ideal for high-pressure applications. Stainless steel pipes, on the other hand, are resistant to corrosion and are often used in industries where hygiene is a priority, such as food processing and pharmaceuticals. Alloy steel pipes offer a combination of strength, toughness, and corrosion resistance, making them suitable for a wide range of applications.

Another important factor to consider when choosing a seamless steel pipe and tube is the size and thickness. Seamless steel pipes and tubes come in a variety of sizes and thicknesses to accommodate different pressure and temperature requirements. It’s essential to select the right size and thickness to ensure that the pipe can withstand the conditions it will be exposed to in your project. Consulting with a professional engineer or supplier can help you determine the appropriate size and thickness for your specific needs.

In addition to material, size, and thickness, it’s also crucial to consider the manufacturing process used to produce the seamless steel pipe and tube. Seamless pipes and tubes are manufactured using either Hot rolling or cold drawing processes. Hot rolling involves heating the steel billet to high temperatures and then rolling it into a seamless pipe or tube. This process results in a smooth surface finish and uniform grain structure, making hot-rolled pipes and tubes suitable for high-temperature and high-pressure applications. Cold drawing, on the other hand, involves pulling the steel billet through a die to form a seamless pipe or tube. This process produces pipes and tubes with tighter tolerances and improved surface finish, making them ideal for precision applications.

https://youtube.com/watch?v=4erHivkeuv4

When choosing a seamless steel pipe and tube for your project, it’s essential to consider the specific requirements and conditions it will be exposed to. Factors such as material, size, thickness, and manufacturing process all play a crucial role in determining the suitability of the pipe for your project. Consulting with a professional engineer or supplier can help you make an informed decision and ensure that you choose the right seamless steel pipe and tube for your specific needs. By taking the time to consider these factors, you can ensure that your project is completed successfully and efficiently.