Understanding the Dimensions of Seamless Tubes According to ASME B36.10M Standard

Seamless tubes are a critical component in various industries, including Oil and gas, petrochemical, and power generation. These tubes are used for conveying fluids and gases at high temperatures and pressures, making them essential for the safe and efficient operation of industrial processes. To ensure the seamless tubes meet the required specifications and standards, it is essential to understand the dimensions and weights as per the ASME B36.10M standard.

The ASME B36.10M standard provides guidelines for the dimensions and weights of seamless steel pipes and tubes. This standard is widely used in the industry to ensure uniformity and consistency in the manufacturing and use of seamless tubes. By adhering to the ASME B36.10M standard, manufacturers can guarantee that their products meet the necessary requirements for quality and performance.

According to the ASME B36.10M standard, seamless tubes are classified based on their nominal Pipe size (NPS) and schedule number. The NPS is a numerical designation that indicates the approximate outside diameter of the tube, while the schedule number refers to the Wall thickness of the tube. Together, the NPS and schedule number determine the dimensions and weights of the seamless tube.

Seamless tubes are available in a wide range of sizes, from 1/8 inch to 36 inches in diameter. The standard specifies the dimensions and weights for each size of seamless tube, ensuring that manufacturers and users have a clear understanding of the specifications. By following the guidelines set forth in the ASME B36.10M standard, manufacturers can produce seamless tubes that meet the required dimensions and weights for their intended applications.

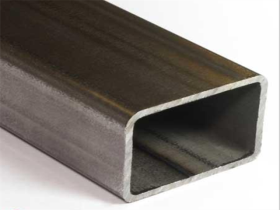

1 4 Tubing steel

In addition to the dimensions, the ASME B36.10M standard also provides guidelines for the weights of seamless tubes. The Weight of a seamless tube is determined by its dimensions, including the outside diameter, wall thickness, and Length. By calculating the weight of the tube, manufacturers can ensure that it meets the necessary requirements for strength and durability.

Transitional phrases such as “in addition to,” “according to,” and “together, the NPS and schedule number” help guide the reader through the article and connect the different ideas presented. By using these transitional phrases, the article flows smoothly from one concept to the next, making it easier for the reader to follow along and understand the information being presented.

Overall, understanding the dimensions and weights of seamless tubes according to the ASME B36.10M standard is essential for ensuring the quality and performance of these critical components. By following the guidelines set forth in the standard, manufacturers can produce seamless tubes that meet the necessary specifications for their intended applications. Adhering to the ASME B36.10M standard helps to promote uniformity and consistency in the manufacturing and use of seamless tubes, ultimately leading to safer and more efficient industrial processes.