Benefits of Using Seamless steel Pipes in Various Industries

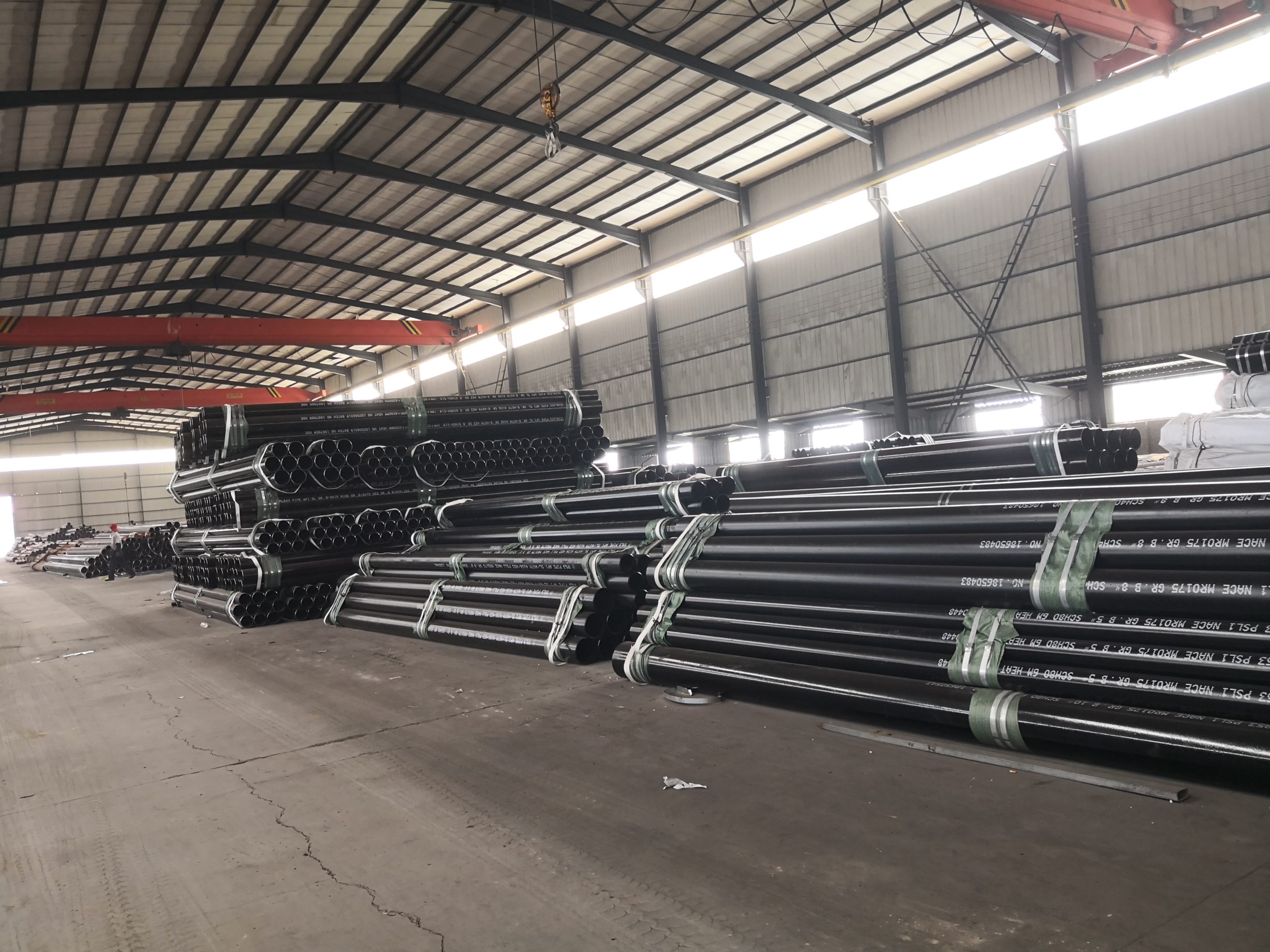

Seamless steel pipes are a crucial component in various industries due to their numerous benefits and applications. These pipes are made from solid round steel billets that are heated and pierced to create a hollow tube. The absence of a seam in seamless steel pipes makes them stronger and more reliable than welded pipes, making them ideal for high-pressure applications.

One of the key benefits of using seamless steel pipes is their ability to withstand high pressure and temperature. The seamless construction of these pipes eliminates the weak points that are often found in welded pipes, making them suitable for transporting fluids and gases at high pressures. This makes seamless steel pipes a popular choice in industries such as Oil and gas, petrochemical, and power generation.

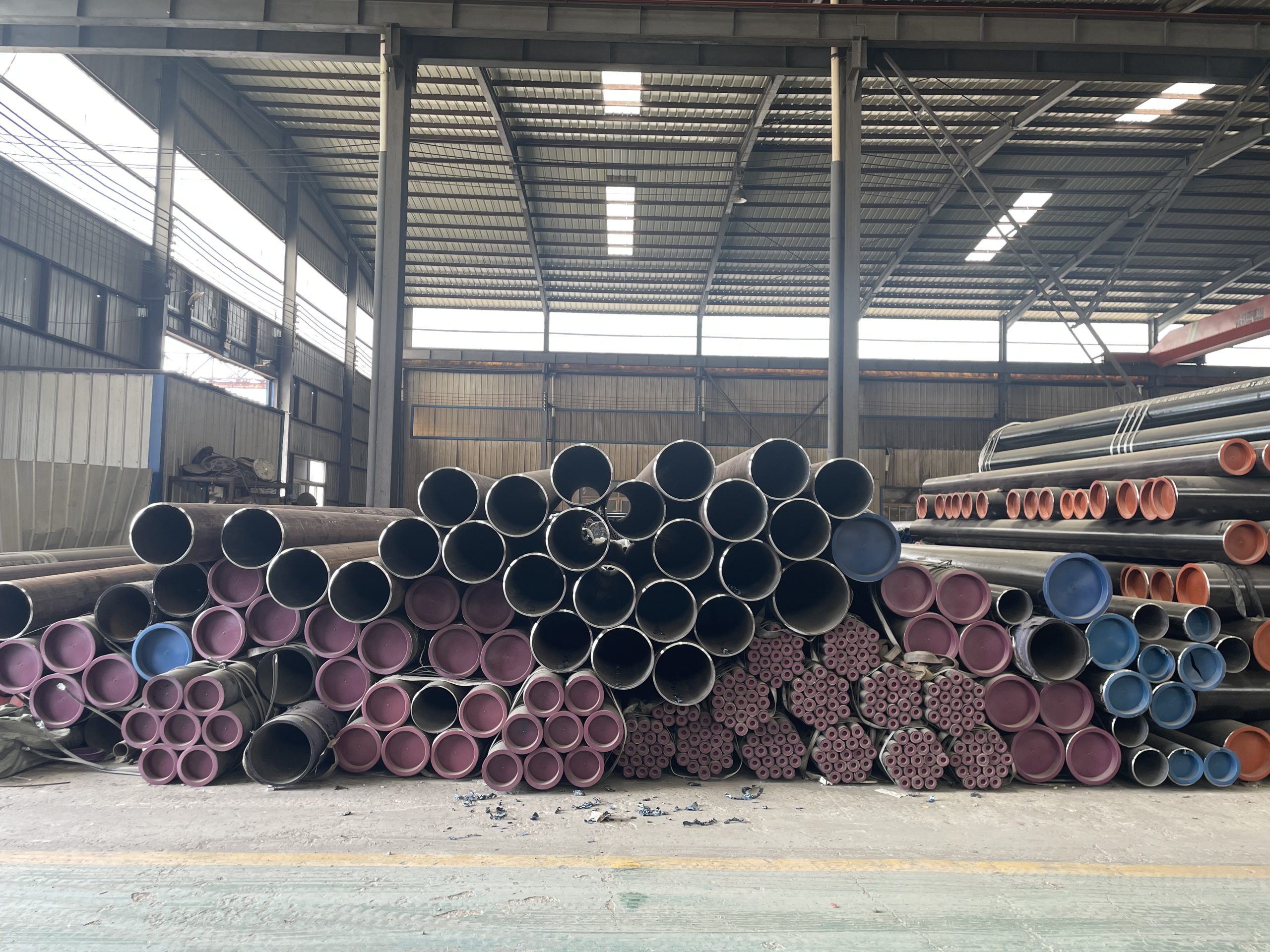

Another advantage of seamless steel pipes is their uniformity in shape and size. The seamless manufacturing process ensures that each Pipe is consistent in diameter and Wall thickness, which is essential for applications that require precise measurements. This uniformity also makes seamless steel pipes easier to install and maintain, reducing the risk of leaks and failures.

Seamless steel pipes are also known for their Corrosion resistance. The absence of a seam in these pipes eliminates the possibility of corrosion along the weld line, making them more durable and long-lasting. This corrosion resistance is particularly important in industries such as chemical processing, where exposure to corrosive substances can cause damage to traditional pipes.

In addition to their strength and durability, seamless steel pipes are also highly versatile. These pipes can be manufactured in a wide range of sizes and shapes to meet the specific requirements of different industries. Whether it’s for transporting water, gas, oil, or steam, seamless steel pipes can be customized to suit a variety of applications.

Furthermore, seamless steel pipes are known for their smooth interior surface, which allows for efficient flow of fluids and gases. The absence of seams and welds in these pipes reduces friction and turbulence, resulting in lower pressure drop and energy consumption. This makes seamless steel pipes an energy-efficient option for industries that require the transportation of large volumes of fluids.

1 inch square metal tubingOverall, the benefits of using seamless steel pipes in various industries are clear. From their strength and durability to their corrosion resistance and versatility, seamless steel pipes offer numerous advantages over welded pipes. Whether it’s for high-pressure applications in the oil and gas industry or for precise measurements in the chemical processing industry, seamless steel pipes are a reliable and efficient choice for transporting fluids and gases.