Benefits of Using Stainless steel Pipe for Sewage Treatment

Stainless steel pipes have become a popular choice for sewage treatment applications due to their numerous benefits. These pipes are made from a durable and corrosion-resistant Material that can withstand the harsh conditions of sewage systems. In this article, we will explore the advantages of using stainless steel pipes for sewage treatment.

One of the main benefits of stainless steel pipes is their resistance to corrosion. Sewage contains various chemicals and substances that can cause corrosion in traditional pipes, leading to leaks and contamination of the surrounding environment. Stainless steel pipes are highly resistant to corrosion, making them a reliable choice for sewage treatment plants.

In addition to their Corrosion resistance, stainless steel pipes are also known for their strength and durability. These pipes can withstand high pressure and temperature fluctuations, making them ideal for sewage treatment applications where the conditions can be harsh and demanding. Stainless steel pipes have a long lifespan, reducing the need for frequent replacements and maintenance, which can save time and money in the long run.

Another advantage of using stainless steel pipes for sewage treatment is their hygienic properties. Stainless steel is a non-porous material that is easy to clean and maintain, making it a sanitary choice for handling sewage. The smooth surface of stainless steel pipes prevents the buildup of bacteria and other contaminants, ensuring that the sewage remains clean and safe for treatment.

Stainless steel pipes are also environmentally friendly. These pipes are 100% recyclable, making them a sustainable choice for sewage treatment plants. By using stainless steel pipes, sewage treatment facilities can reduce their carbon footprint and contribute to a more sustainable future.

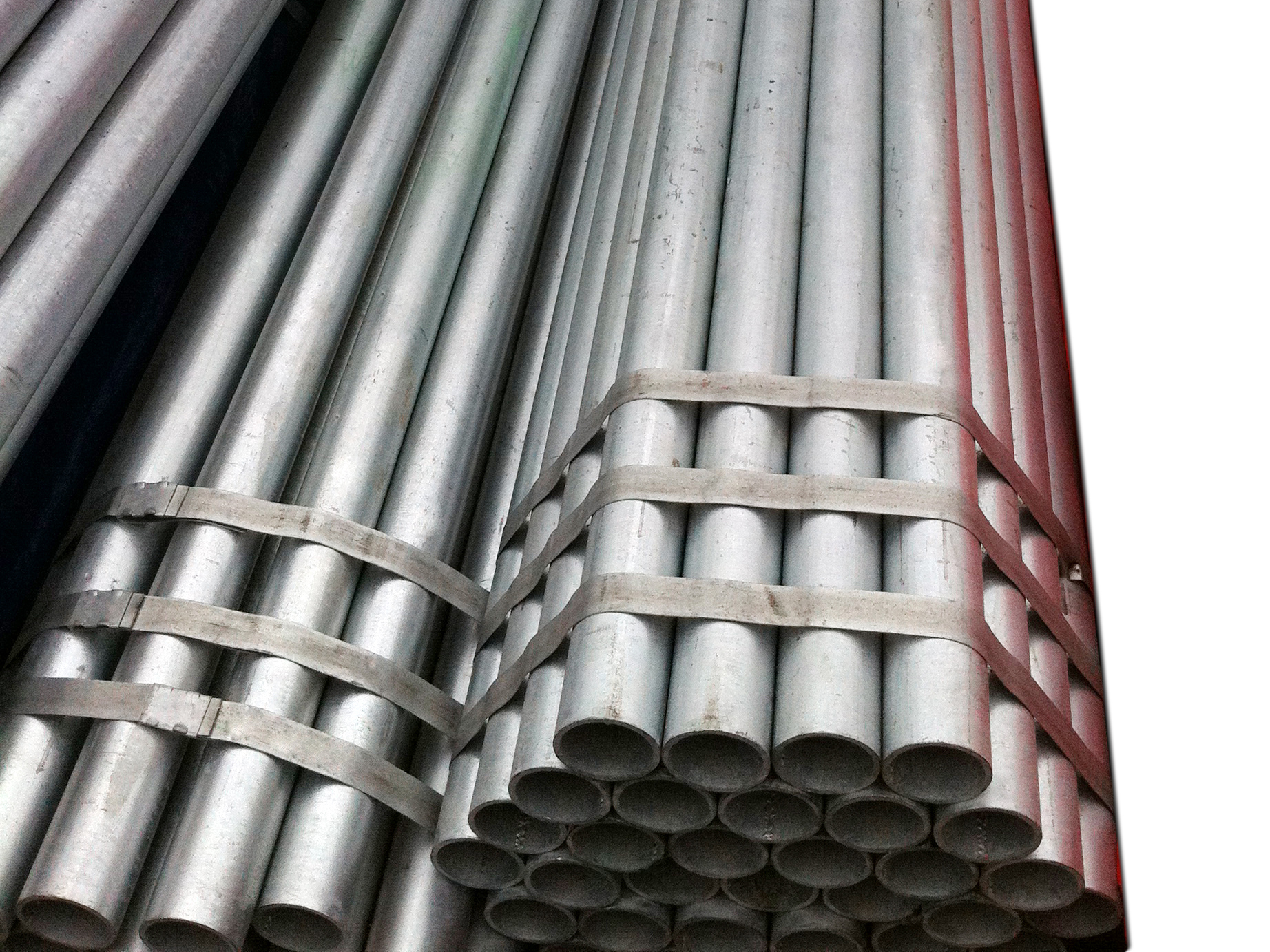

Furthermore, stainless steel pipes are versatile and can be customized to meet the specific needs of sewage treatment plants. These pipes come in a variety of sizes and thicknesses, allowing for flexibility in design and installation. Stainless steel pipes can be welded or Seamless, depending on the requirements of the project, making them a versatile choice for sewage treatment applications.

In conclusion, stainless steel pipes offer numerous benefits for sewage treatment plants. From their corrosion resistance and durability to their hygienic properties and environmental friendliness, stainless steel pipes are a reliable and sustainable choice for handling sewage. By using stainless steel pipes, sewage treatment facilities can ensure the safety and efficiency of their operations while contributing to a more sustainable future.

Comparison of Different Grades of Stainless Steel Pipe for Sewage Treatment

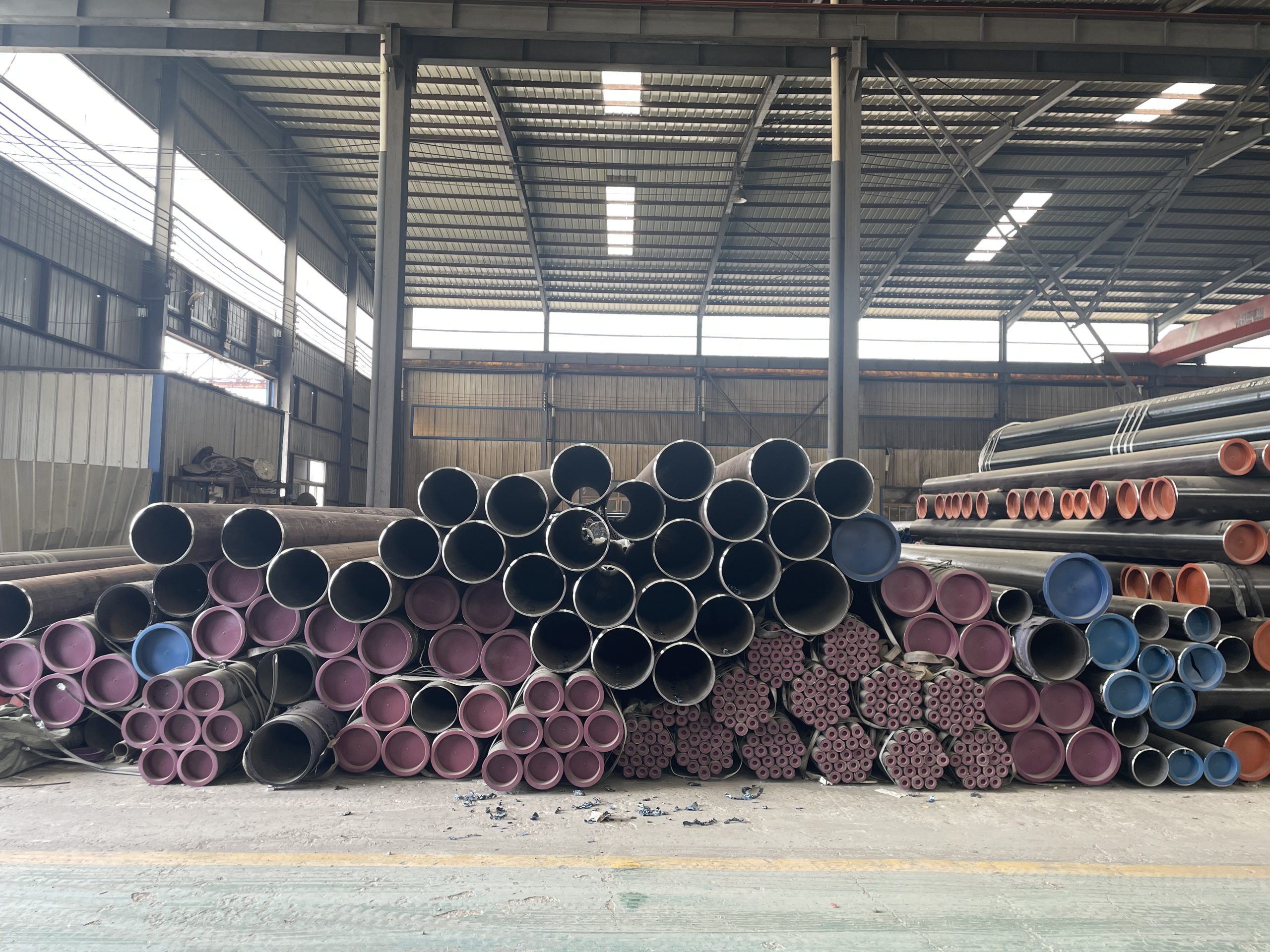

Stainless steel pipes are widely used in sewage treatment plants due to their corrosion resistance, durability, and strength. When it comes to choosing the right grade of stainless steel pipe for sewage treatment applications, there are several options available, each with its own unique properties and advantages. In this article, we will compare different grades of stainless steel pipes commonly used in sewage treatment plants, including 304, 304L, 304H, 316, 316L, 316H, 321, 32H, 317L, 347, 347H, 310S, 310, and 310H seamless pipes.

304 stainless steel is one of the most commonly used grades in sewage treatment plants due to its excellent corrosion resistance and ease of fabrication. It is suitable for a wide range of applications, including transporting wastewater and chemicals. 304L stainless steel is a low-carbon variant of 304, which offers improved weldability and resistance to sensitization. 304H stainless steel, on the other hand, has a higher carbon content, making it suitable for high-temperature applications.

316 stainless steel is another popular choice for sewage treatment plants, thanks to its superior corrosion resistance, especially in harsh environments. 316L stainless steel is a low-carbon variant of 316, which offers improved weldability and resistance to intergranular corrosion. 316H stainless steel, with its higher carbon content, is suitable for high-temperature and high-pressure applications.

321 stainless steel is a stabilized grade that offers excellent resistance to intergranular corrosion and high temperatures. 321H stainless steel is a high-carbon variant of 321, which provides improved creep resistance and strength at elevated temperatures. 317L stainless steel is a low-carbon variant of 317, which offers improved resistance to sensitization and corrosion in acidic environments.

347 stainless steel is a stabilized grade that offers excellent resistance to intergranular corrosion and high temperatures. 347H stainless steel is a high-carbon variant of 347, which provides improved creep resistance and strength at elevated temperatures. 310S stainless steel is a high-temperature grade that offers excellent resistance to oxidation and sulfidation. 310 stainless steel is a general-purpose grade that offers good corrosion resistance and high-temperature strength. 310H stainless steel is a high-carbon variant of 310, which provides improved creep resistance and strength at elevated temperatures.

In conclusion, when choosing a grade of stainless steel pipe for sewage treatment applications, it is essential to consider factors such as corrosion resistance, weldability, temperature resistance, and strength. Each grade of stainless steel pipe has its own unique properties and advantages, so it is crucial to select the right grade based on the specific requirements of the sewage treatment plant. By comparing different grades of stainless steel pipes, sewage treatment plant operators can make an informed decision and ensure the long-term performance and reliability of their piping systems.