Benefits of Using Wholesale Black Mirror 304 316 2205 Round ASTM A270 304 316 254 Smo Seamless Pipe

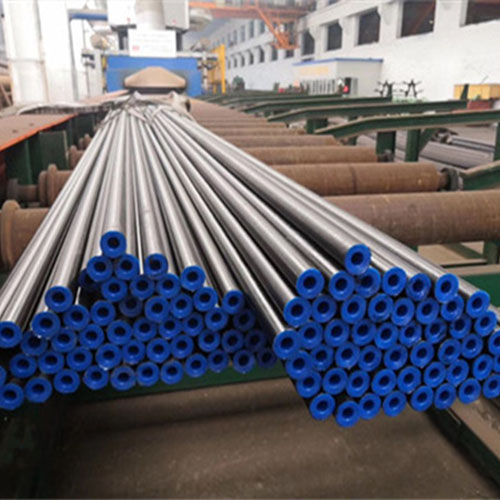

Stainless steel pipes are a crucial component in various industries, including construction, automotive, and manufacturing. When it comes to choosing the right stainless steel pipe for your project, wholesale black mirror 304 316 2205 round ASTM A270 304 316 254 smo seamless pipes are an excellent option. These pipes offer a range of benefits that make them a popular choice among professionals in the industry.

One of the key advantages of using wholesale black mirror stainless steel pipes is their durability. These pipes are made from high-quality materials that are resistant to corrosion, rust, and other forms of damage. This means that they can withstand harsh environmental conditions and heavy usage without deteriorating. As a result, wholesale black mirror stainless steel pipes have a longer lifespan compared to other types of pipes, making them a cost-effective investment in the long run.

In addition to their durability, wholesale black mirror stainless steel pipes are also known for their strength. These pipes have a high Tensile strength, which means they can withstand high pressure and heavy loads without bending or breaking. This makes them ideal for applications that require a reliable and sturdy piping system, such as in industrial settings or construction projects.

Another benefit of using wholesale black mirror stainless steel pipes is their versatility. These pipes come in a variety of sizes, shapes, and thicknesses, making them suitable for a wide range of applications. Whether you need a small diameter pipe for a residential plumbing project or a large diameter pipe for an industrial application, wholesale black mirror stainless steel pipes can meet your requirements.

Furthermore, wholesale black mirror stainless steel pipes are easy to work with. They can be cut, bent, and welded to fit specific project requirements, making them a flexible and customizable option for professionals in the industry. This versatility allows for easy installation and maintenance, saving time and effort during the construction process.

In addition to their practical benefits, wholesale black mirror stainless steel pipes also offer aesthetic advantages. The black mirror finish of these pipes gives them a sleek and modern look that can enhance the visual appeal of any project. Whether used in a residential, commercial, or industrial setting, wholesale black mirror stainless steel pipes can add a touch of sophistication and style to the overall design.

Overall, wholesale black mirror 304 316 2205 round ASTM A270 304 316 254 smo seamless pipes are a reliable and cost-effective choice for professionals in the industry. With their durability, strength, versatility, and aesthetic appeal, these pipes offer a range of benefits that make them a popular option for a wide range of applications. Whether you are working on a small-scale project or a large industrial installation, wholesale black mirror stainless steel pipes can meet your needs and exceed your expectations.

Techniques for Cutting and Bending Seamless Stainless Steel Pipe

Stainless steel is a versatile and durable Material that is commonly used in a wide range of industries, from construction to automotive to food processing. One of the key advantages of stainless steel is its resistance to corrosion, making it an ideal choice for applications where exposure to moisture or harsh chemicals is a concern. Seamless stainless steel pipe, in particular, is prized for its smooth, uniform surface and high strength, making it a popular choice for piping systems in a variety of industries.

When it comes to working with seamless stainless steel pipe, cutting and bending are two essential techniques that are often required to create custom piping systems that meet specific project requirements. In this article, we will explore some of the techniques and tools that are commonly used for cutting and bending seamless stainless steel pipe.

Cutting seamless stainless steel pipe requires precision and care to ensure a clean, straight cut that does not damage the integrity of the pipe. One of the most common methods for cutting stainless steel pipe is using a circular SAW with a carbide-tipped blade specifically designed for cutting metal. This method is fast and efficient, but it can generate a significant amount of heat, which can cause the stainless steel to warp or discolor. To minimize heat buildup, it is important to use a cutting fluid or lubricant to cool the blade and reduce friction during the cutting process.

Another popular method for cutting seamless stainless steel pipe is using a plasma cutter. Plasma cutting is a versatile and efficient cutting technique that uses a high-temperature plasma arc to melt through the stainless steel. This method is ideal for cutting thick stainless steel pipe or for creating intricate shapes and designs. However, plasma cutting can produce a rough edge that may require additional finishing to achieve a smooth, clean surface.

Once the seamless stainless steel pipe has been cut to the desired Length, it may need to be bent or shaped to fit the specific requirements of the project. Bending stainless steel pipe can be a challenging task, as the material is known for its high strength and resistance to deformation. One of the most common methods for bending stainless steel pipe is using a hydraulic pipe bender. Hydraulic pipe benders are powerful machines that use hydraulic pressure to bend the pipe around a die to achieve the desired angle or radius. This method is ideal for creating smooth, uniform bends in stainless steel pipe without causing damage to the material.

Another popular method for bending seamless stainless steel pipe is using a mandrel bender. Mandrel benders are precision machines that use a mandrel, or rod, inserted into the pipe to support the inner wall and prevent it from collapsing during the bending process. This method is ideal for creating tight-radius bends in stainless steel pipe without causing wrinkling or distortion.

In conclusion, cutting and bending seamless stainless steel pipe require precision, skill, and the right tools to achieve professional results. By using the techniques and tools outlined in this article, you can create custom piping systems that meet the specific requirements of your project while maintaining the high quality and durability that stainless steel is known for. Whether you are working in construction, manufacturing, or any other industry that requires stainless steel piping, mastering the techniques for cutting and bending seamless stainless steel pipe is essential for achieving success in your projects.